Plasma polymerization and chemical functionalization

The COAD® process as a versatile tool for controlling adhesion in surface treatment and coating

The COAD® (COntrolled ADhesion) process developed at Fraunhofer IST can be used to chemically functionalize or coat planar and 3D surfaces in order to optimize adhesion in a targeted manner. First, the materials are functionalized or cleaned by reactive species in the plasma. Subsequently, a precursor is added to the gas during plasma polymerization, which is activated by the plasma and creates an extremely thin, highly reactive layer on the surface. The right choice of precursor enables a wide range of layer functions. The coatings applied using the COAD® process can increase the adhesion of adhesives and sealants, paints and varnishes, or biological molecules such as proteins or cells, as well as create non-stick properties and antimicrobial or switchable surfaces.

Sustainable process without wet chemistry and energy-intensive intermediate steps

As so-called “cold plasmas”, plasmas at atmospheric pressure or in a rough vacuum offer many advantages, particularly in the functionalization and coating of temperature-sensitive materials. Since the processes take place at or near ambient pressure and do not require wet chemistry or time-consuming drying steps, they can be easily integrated into existing process chains. Thanks to the equipment available at Fraunhofer IST and many years of process experience, the COAD® process can be flexibly adapted to different materials, component sizes, and quantities. In addition, it causes very low CO₂ emissions, especially when using renewable energies.

Outlook – This is what awaits you!

The expansion of plasma polymerization to high-molecular, complex film formers opens up new potential applications that currently still require a combination of plasma and wet chemical processes. In addition, we are also addressing triggerable adhesion systems in order to further optimize material cycles and enable materials to be reused or recycled despite being coated.

In terms of scalability, the COAD® process also offers great potential for even more sustainable design – especially when precursors from waste streams can be used.

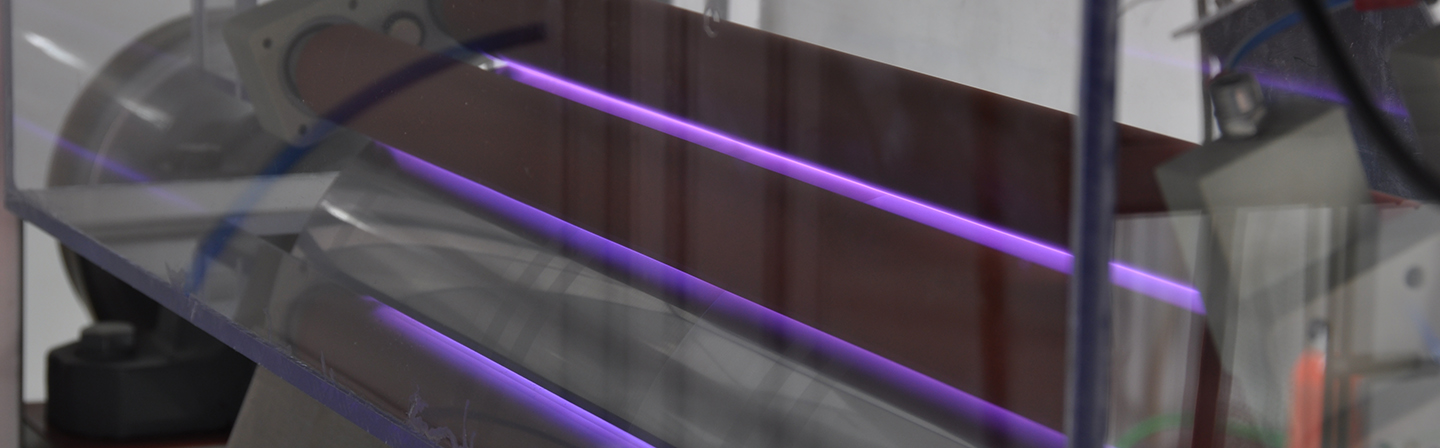

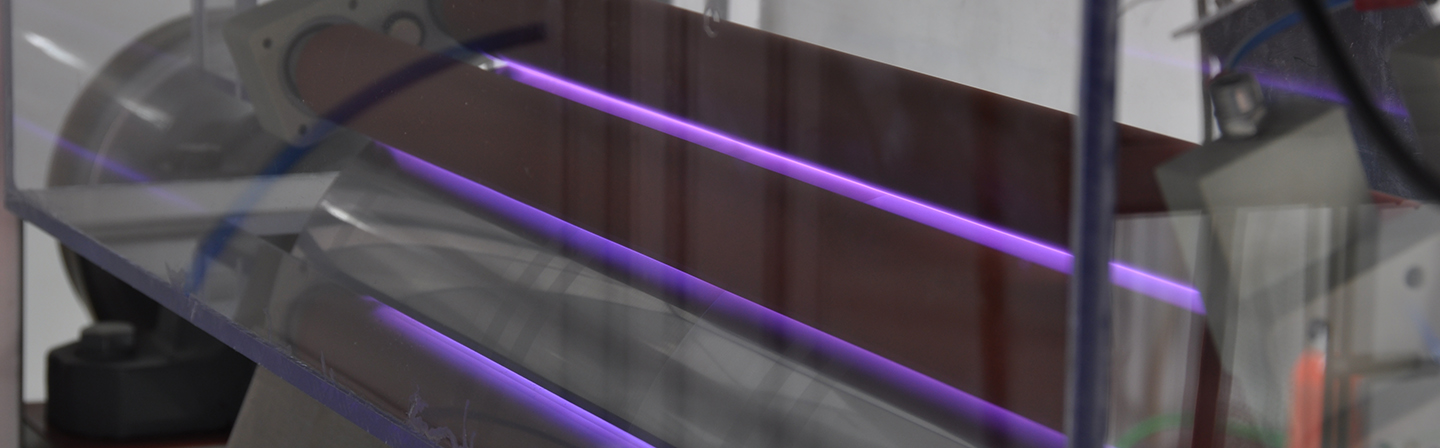

Facilities for functionalization and coating

At the Fraunhofer IST, a number of facilities are available for the functionalization and coating of planar and three-dimensional substrates using plasma processes at atmospheric pressure and in rough vacuum. The systems are based on the principle of dielectric barrier discharge (DBE) and are suitable for both conductive and insulating materials. The processes can be carried out both in batch processes and in a roll-to-roll system. The focus of the work at IST is the development of new coating processes for the optimization of the functionality of the base material.

Specifications / Technical data

- Roll-to-roll systems at atmospheric pressure with treatment speeds of up to 30 m/min

- Batch processes at atmospheric pressure for sheets measuring 1000 x 350 x 3 mm³

- Batch processes in a rough vacuum for components measuring up to 800 x 800 x 400 mm³

- Plasma jets on cobots and in additive manufacturing for local treatment and coating

- High oxygen-free process control possible

- Coating and functionalization to control adhesion

- Development of customized electrode systems