Digitization of electroplating production processes

Innovative solutions in the area of sustainable process development and control as well as in quality management

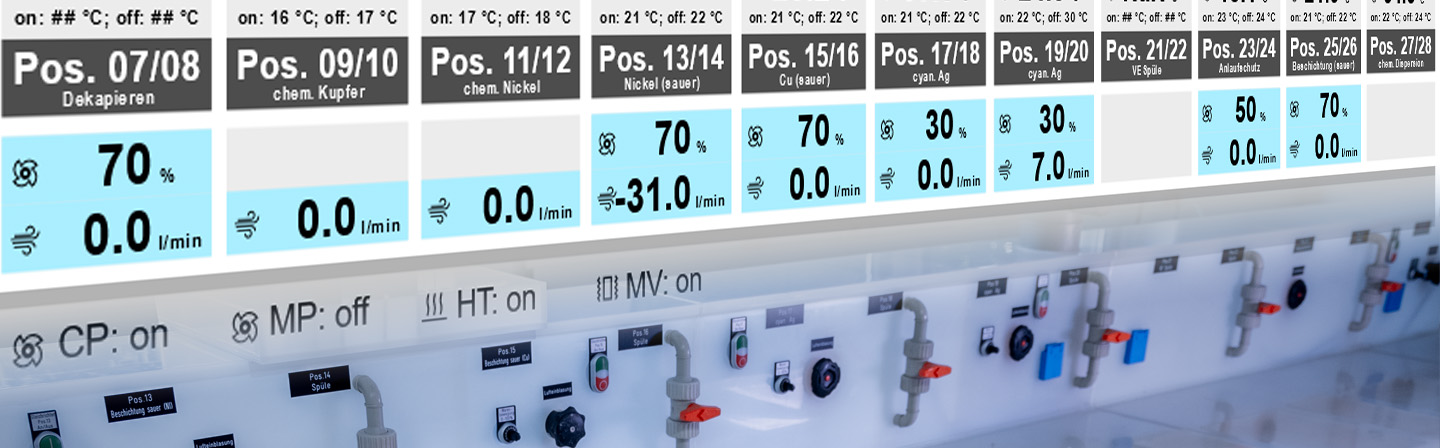

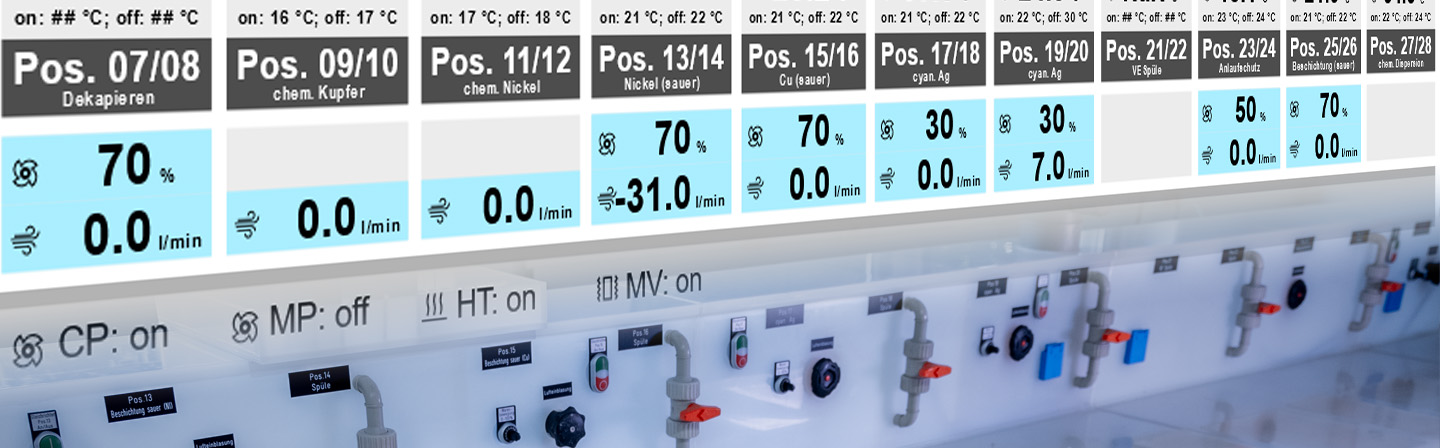

Modular plant concepts with extensive inline, online and atline analytics as well as specifically developed software solutions for automated data acquisition and processing enable the digital mapping of electroplating production processes at the Fraunhofer IST. We thereby pursue the goal of controlling and optimizing the processes on the basis of models as well as predicting the necessary maintenance. As a result, the quality, throughput and reproducibility of the coating processes can be improved with simultaneous resource efficiency, thereby creating the basis for a circular economy.

Life-cycle assessment in parallel with REACH-compliant process development for the most diverse products, processes and services in electroplating technology

Since the European chemicals regulation REACH came into force in 2007, increased attempts have been made to find substitutes for critical substances such as chromium(VI). In many cases, however, solely the replacement of the critical input substances has been addressed, whilst the potential shifting of problems to other life-cycle phases and environmental-impact categories has not been taken into consideration. At the Fraunhofer IST, a systematic analysis of environmental effects is therefore being increasingly carried out, parallel to the process, with the aid of a life-cycle assessment in accordance with ISO 14040. The aim is to avoid such problem shifts throughout the entire life cycle.

“Through the utilization of digital methods, we see the possibility of making electroplating processes more agile, flexible and sustainable in the future.”

Rowena Duckstein M.Sc. / Group Manager