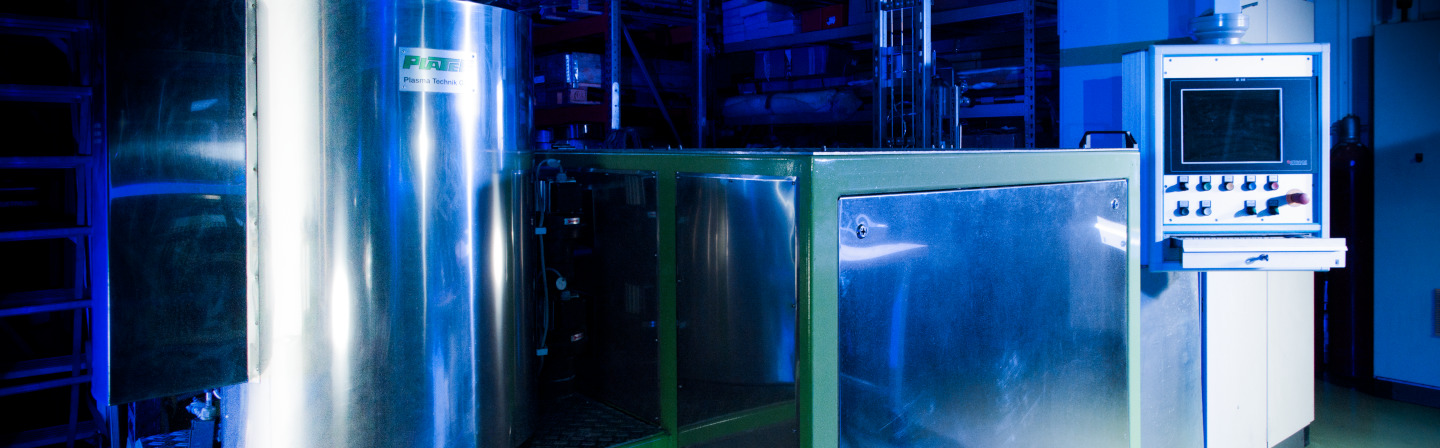

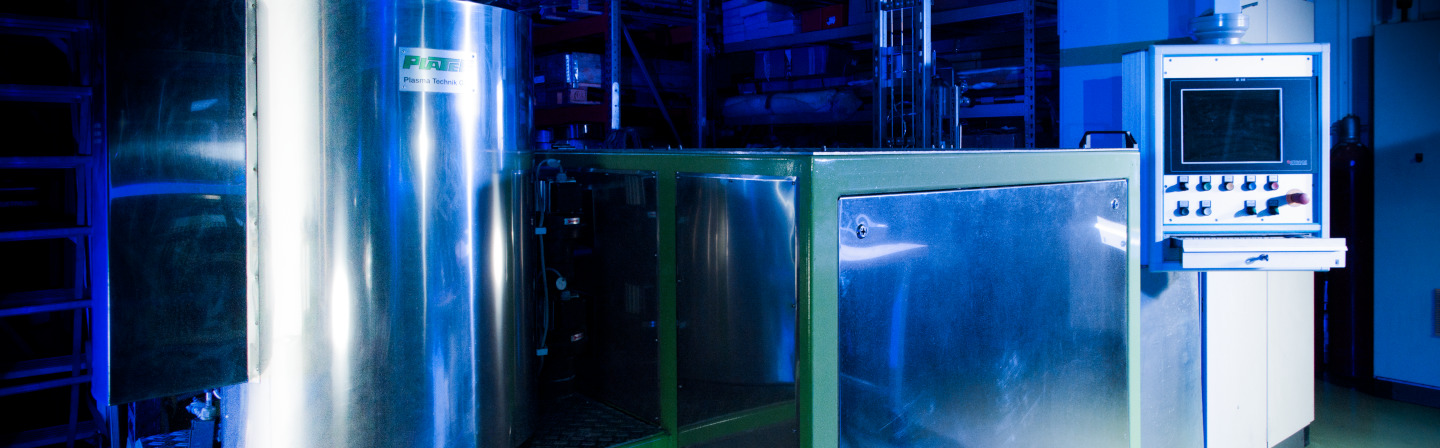

Chemical, mechanical and thermal surface treatment

Applying the optimal surface treatment to create the desired functional surface

Surface treatment is a complex interaction of an entire series of decisions that need to be made in order to develop a (surface) system that is appropriate for the customer. The initial step is the definition of the functional surface as regards the requirements. The Fraunhofer IST can hereby provide advice and guidance. The resulting surface treatment usually consists of several steps.

Our service for you – The solution for your application

The configuration of the topography thereby forms the first adapted modification. In addition, a subsequent cleaning in our wet-chemical cleaning facility can be performed, before a variety of surface treatments can be carried out. Subsequently, various surface treatments with nitrogen, boron or metallic elements are available. A further option is offered through targeted decoating by chemical or mechanical means.

We would be pleased to advise you concerning your specific requirements.