Innovative composite layers by means of atmospheric PECVD

Lamination plates are currently used, for example, in the production of documents such as passports, driving licenses, national identity cards and bank cards. The trend towards integrating more and more functions and features on such cards is, however, placing more intensive demands on the lamination process and on increasingly finer structures. Structures with a thickness of nm and a width of merely µm are desired on the film. At present, however, it is not possible to produce these as the adhesion between the substrate and the laminating tool is too high, as a result of which parts of the polymer remain stuck to the metal plate following the lamination process. The Fraunhofer IST is therefore working on a suitable non-stick coating for the surface of the lamination plates; this solution should solve these problems and, furthermore, enable the use of materials such as polyethylene terephthalate glycol and polyurethane (PET-G and PU) in the future.

The solution approach

Within the scope of the BMBF-funded project “MONK” (Funding ref.: 13XP5046), a new type of non-stick coating on the basis of composite materials was researched at the Fraunhofer IST. The coatings, which are produced from process gases with two different silicon precursors, are characterized by good adhesion to the substrate material and, at the same time, excellent non-stick behavior with respect to various polymers.

Innovative material classes with optimum surface properties

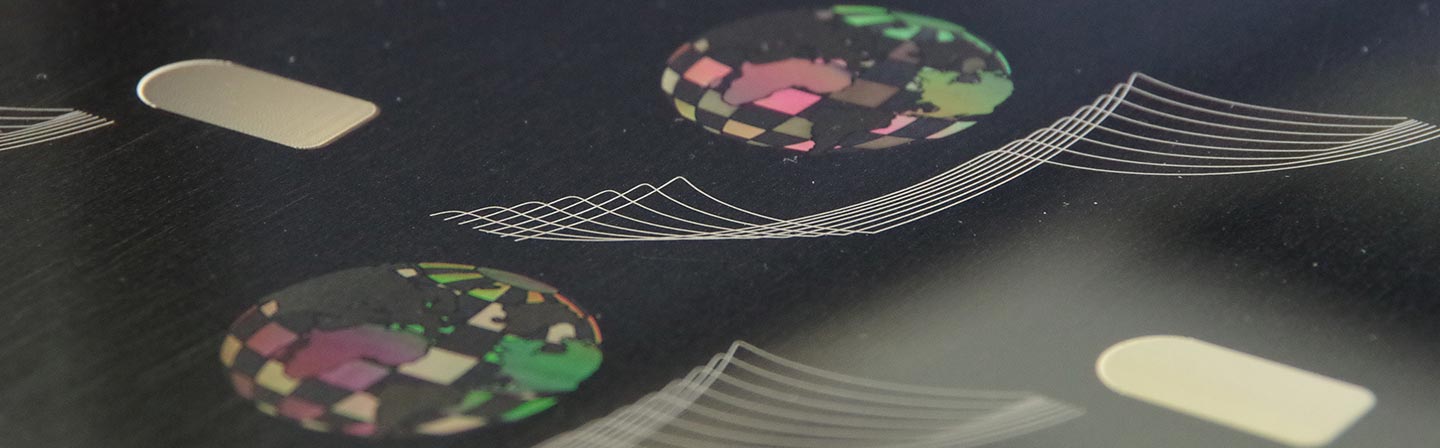

In a first step, potentially suitable layer-formers were selected, namely two silicon-containing compounds, one of which has adhesion-promoting properties and the other non-stick properties. The layer-formers were applied – sometimes also as a mixture – in order to produce three different types of composite coatings on the lamination plates by means of atmospheric-pressure plasma processes (see adjacent above Figure):

1. Nanolaminate: This coating consists of two different individual layers of only a few nanometers in thickness, which are deposited alternately. The undermost layer is the adhesion-promoting layer, whilst the uppermost layer is the non-stick coating.

2. Gradient: The gradient layer is characterized by two precursors which change their concentrations in opposite directions across the layer thickness in order to achieve a smooth transition from the adhesion-promoting layer to the non-stick layer

3. Copolymer: Here, both precursors are mixed before entering the plasma zone and simultaneously deposited on the substrate, thereby forming a tight network.

The results

After coating, the lamination plates were brought together with polyurethane (PU) films under specific pressure and temperature and separated again for evaluation of the layers by means of peel tests.

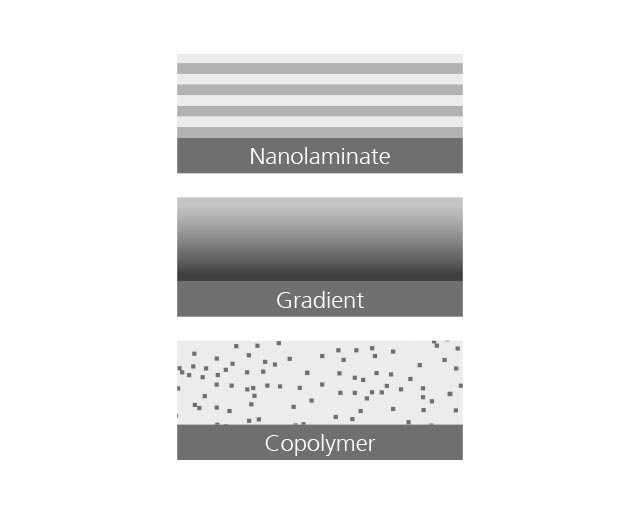

The graph in the middle shows subtracted ATR-FTIR spectra generated by measuring the polymer films after lamination and the subsequent peel test. Following the measurement, reference spectra were subtracted from the measured spectra and peak areas were determined. Peaks in the wave number range of 1000 – 1200 cm-1 are attributed to the presence of Si-O bonds in the plasma coatings. A comparison of the peak areas of the three different coating systems showed that in the case of the copolymer, a significant amount of the coating was transferred to the polymer during the lamination process. In contrast, the spectra of the gradient and nanolaminate coatings did not show any vibration bands typical for the Si-O bond, which is considered proof that no coating transfer has occurred. Consequently, the gradient and nanolaminate coatings are fundamentally suitable for a coating between lamination plate and film.

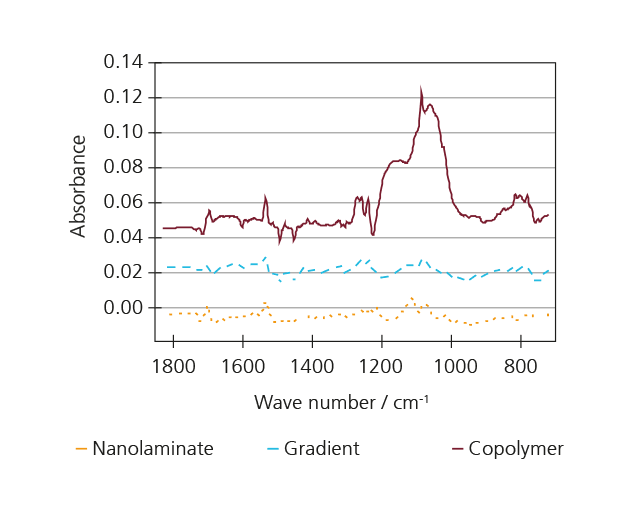

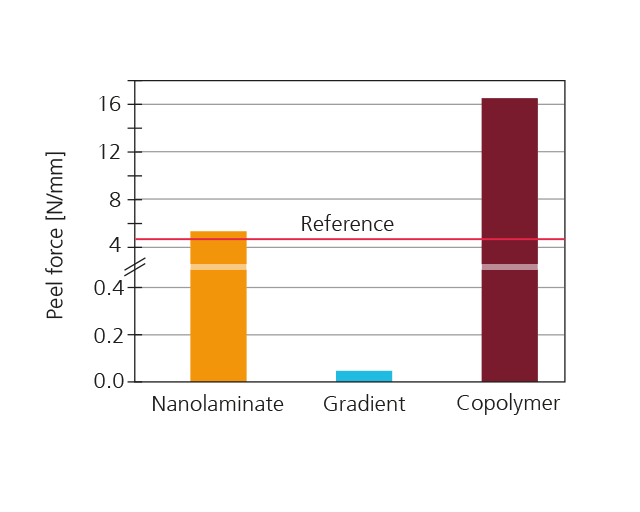

The lower diagram shows the peel-off values of the sheets. The non-stick effect of the copolymer is very weak. It seems to adhere strongly on both sides, both on the lamination plate and on the laminated film. During the peel test, the coating exhibits a coherent failure due to the strong adhesion at both interfaces. In contrast, the nanolaminate yielded significantly better results than the copolymer. Here, the peel forces were only one third of those of the copolymer, but no improvement could be observed compared to the uncoated reference.

The best results in terms of the desired non-stick effect were achieved with the gradient layer. Here, the peeling force is 100 times lower than for the reference material. The laminating film more or less “falls” off the lamination plate.

Outlook

Through utilization of the new layers, it will be possible in the future – in addition to the use of further materials – to laminate the most diverse types of plastics by means of robot-assisted automated rapid lamination.

This article is part of the annual report 2019.