Plastic metallization

Environmentally friendly plastic pretreatment and metallization

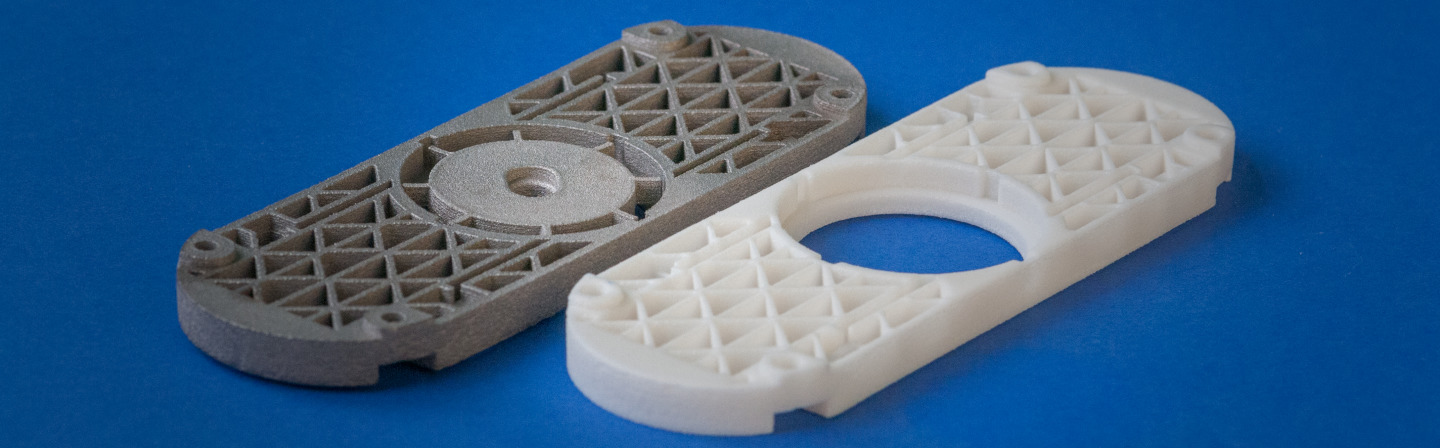

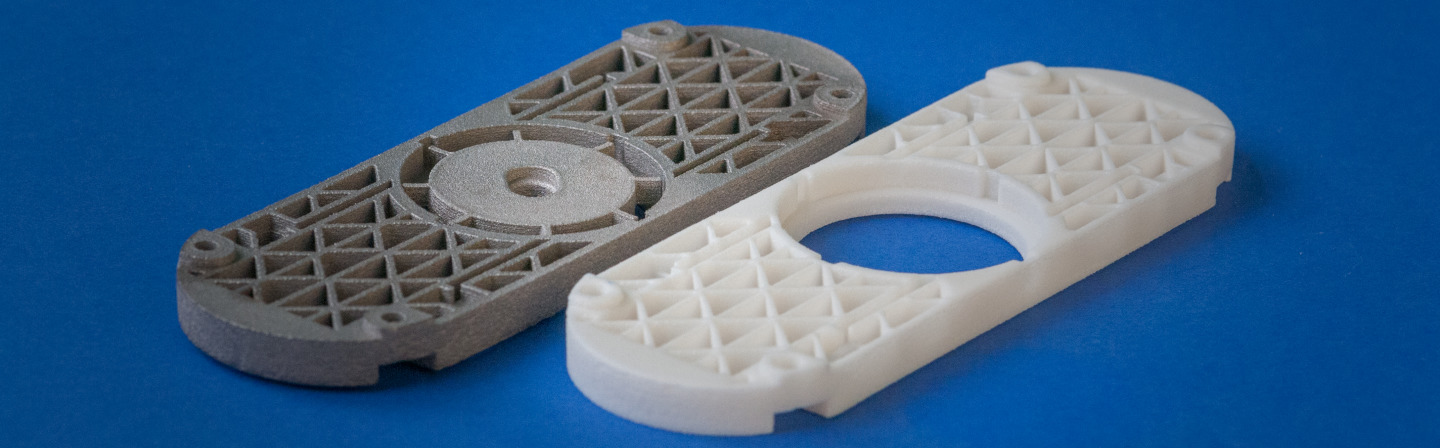

Via metallization of the surface, the functional and decorative properties of the plastic component are adjusted. The many years of expertise accumulated by the Fraunhofer IST in this field hereby lie in the REACH-compliant pretreatment of plastics, which is of crucial importance for the quality of the coating. Building on this, a wide variety of metals, alloys, coating systems and multi-material systems are applied with contour precision to surfaces and then tested by means of standardized processes. For the subsequent surface finishing, we offer various metal coatings, alloys and multi-material systems. Special attention is hereby paid to rack construction and process control for complex component geometries.

Together, we make a difference

We offer our customers sustainable process and coating development tailored to their base material and application, beginning with prototypes and extending all the way to scaling-up to industrial scales, subject to the proviso of closed material and substance cycles. Our modern plant technology enables us to react quickly and flexibly to customer requests and to coat even very complex geometries such as additively manufactured components and internal surfaces. We combine this with in-process quality monitoring and film characterization.