Improving inhalation therapy by means of anti-adhesive surfaces

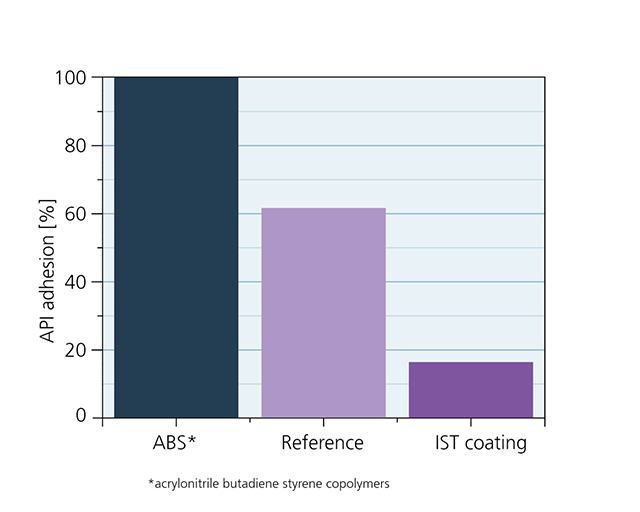

Particularly in the case of chronic lung diseases such as asthma, many people use inhalers in order to ensure that their airways remain unobstructed. However, a proportion of the particles to be inhaled often remains adhered to the inhaler itself. By means of an optimized ultrathin coating of the plastic surfaces in inhalers, the Fraunhofer IST has been able to demonstrate that the surface properties of these medical devices can be specifically adjusted. With the aid of the coating, it was possible to significantly reduce surface adhesion for very fine drug particles. As a result, the application safety of inhalers and the effective utilization of drug doses can be substantially increased.

Small particles – large interactions: Loss of active pharmaceutical substances during application

For the administration of API into the lungs, they must be applied as mists or particle aerosols with a particle size of less than 5 µm in order to reach their target site deep in the respiratory tract. Due to their small size, however, the API particles have a strong tendency to adhere, especially to the surfaces of the inhalers used for their application. This can lead to reduced or fluctuating dose delivery of the API to the patients and, consequently, a jeopardization of therapy safety.

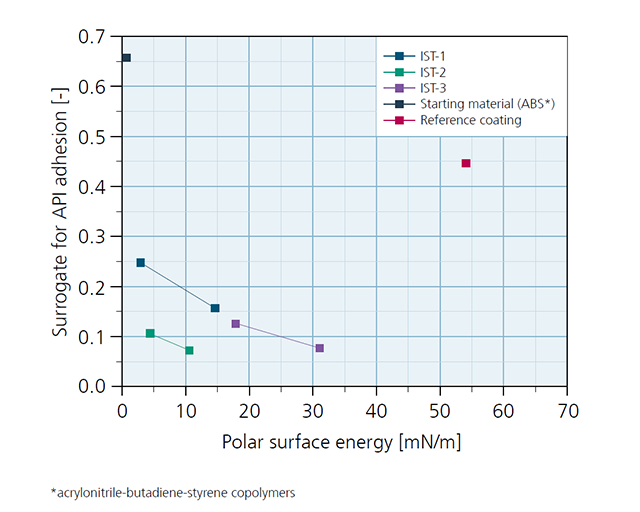

Customized ultrathin coatings significantly inhibit the adhesion of API

Through the functional coating of the inner plastic surfaces of inhalers, their physicochemical properties can be controlled in such a way that the interaction potentials can be aligned to the properties of the API particles, thereby enabling the knowledge-based reduction of the adhesion tendency. The chemical precursors employed for the coating as well as the parameters of the coating process thereby serve the control of the coating properties.

Reduce losses – Improve therapy – Protect the environment

By specifically reducing the deposition of API particles, the dosage of the medication delivered to the patient becomes significantly more precise and reproducible, thereby increasing therapy safety. Furthermore, quantities of API that would otherwise remain in the inhaler can be saved. The cleaning effort for the inhaler is reduced, as is the environmental impact caused by the unused quantities of API removed from the inhaler.

Part of a whole – Pharma-related research at the Fraunhofer IST

Research into the adaptation of the interaction between medication forms and surfaces is part of the still-young field of application for medical and pharmaceutical technology at the Fraunhofer IST. It is located in the High-Performance Center Medical and Pharmaceutical Engineering, in which the IST is active in collaboration with the Fraunhofer Institute for Toxicology and Experimental Medicine ITEM and the Fraunhofer Research Institution for Individualized and Cell-Based Medical Engineering IMTE. Further fields of application of the Fraunhofer IST are here the coating and functionalization of pharmaceutical particle systems, the development of adhesion- and wear-resistant coatings for process equipment and tools, functional coatings of primary packaging materials, and the further development of vaccines.

Outlook

The solution approach for adhesion control in inhalers can be transferred almost generically not only to other fields of application within the pharmaceutical industry but also outside of it, in order to control the deposition of ultra-fine particles, customized to their properties. In combination with the functional coating of API particles, it is possible not only to improve application safety but also, for example, to prolong the release profile of medications and, consequently, their realease profile over time, or to “program” a release in response to specific stimuli.

This article is part of the Annual Report 2021.