Environmentally-friendly surface cleaning

In surface technology, effective surface cleaning plays a key role in the entire production process, because high demands are placed on surface quality even before the coating process.

Cleaning as part of the production process

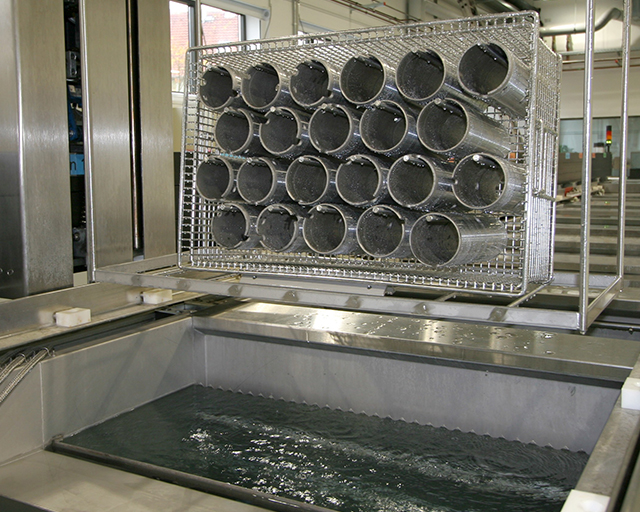

The coating techniques used at the Fraunhofer IST impose high demands on surface quality. Effective surface cleaning consequently plays a key role in the entire production process, because high demands are placed on surface quality even before the coating process. The Fraunhofer IST solves this task by means of a high-performance cleaning technology on an aqueous basis. It is suitable for the preparation of surfaces for subsequent processes, in particular for plasma-supported coating procedures. Aqueous cleaning ensures intensive but gentle cleaning of various materials such as metals, glass, plastics, etc.

Aqueous cleaning is environmentally friendly

Aqueous cleaners are superior to hydrocarbon-based cleaners not only in terms of their cleaning effect in the case of contamination with salts and shavings, but also with regard to their ability to modify the material surface. Aqueous cleaning covers a broad cleaning spectrum from coarse cleaning to ultra-fine cleaning. Furthermore, aqueous systems have a lower environmental impact, are predominantly biodegradable and, as a result, incur lower disposal costs.

Cleaning technology with a modular design

Specific tasks in the cleaning of surfaces require individual solutions. For this purpose, the Fraunhofer IST has designed a high-performance, environmentally-friendly 15-stage facility for cleaning on an aqueous basis. This is composed of the following modules:

- a spray-cleaning chamber (0.5 to 3 bar / up to 70 °C)

- five ultrasonic-assisted immersion baths (up to 40 kHz / up to 70 °C)

- five carryover-minimizing rinsing baths

- a triple cascade for ultra-clean rinsing

- a drying chamber with circulating air, vacuum and inert gas

Specifications / technical data

- Maximum dimensions: 960 x 560 x 360 mm

- Maximum weight: 80 kg

Permanent control over the bath quality

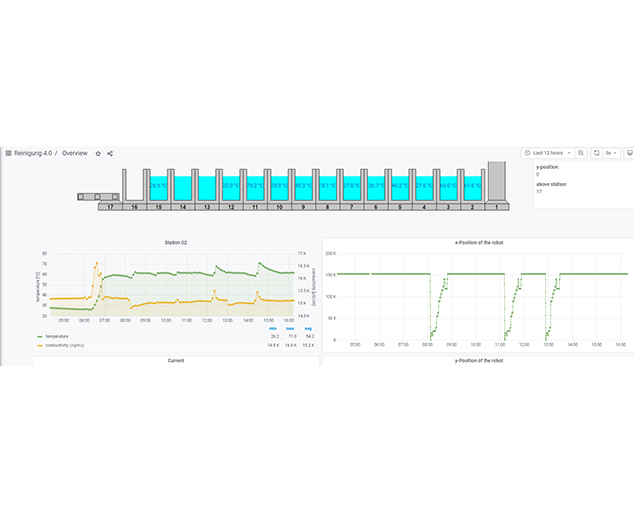

Intelligent flow management of the rinsing liquids, innovative rinsing and treatment techniques, and a powerful automated process-control system result in reproducible, optimum cleaning and spotless surfaces with a very low carryover rate. By means of the integrated sensors, conductivity measurement data, amongst other values, are continuously recorded by all modules of the cleaning line and converted into a control signal for fresh water or detergent dosing to ensure optimum chemical concentration. This results in a consistently high bath quality.

Our range of services: Industrial component cleaning

In process development, customer-specific cleaning operations are possible using a variety of material-optimized chemical cleaning systems, including drying and corrosion protection. We would be pleased to provide you with advice on the integration of a cleaning system into existing manufacturing processes and to support you in the transfer of the cleaning technology into the plant and the training of the employees.

Cleaning 4.0

The ”Reinigung 4.0” (Cleaning 4.0) project has enabled the Fraunhofer IST to tap into new technological competence in the field of cyber-physical systems. It facilitates seamless documentation of all relevant process data and sequences. At the same time, it provides approaches for the further optimization of existing cleaning processes. As the first representative project in the field of “Oberflächentechnik 4.0” (Surface Technology 4.0), it forms the basis for the ongoing modernization at the