The ”Patient room of the future” in Braunschweig

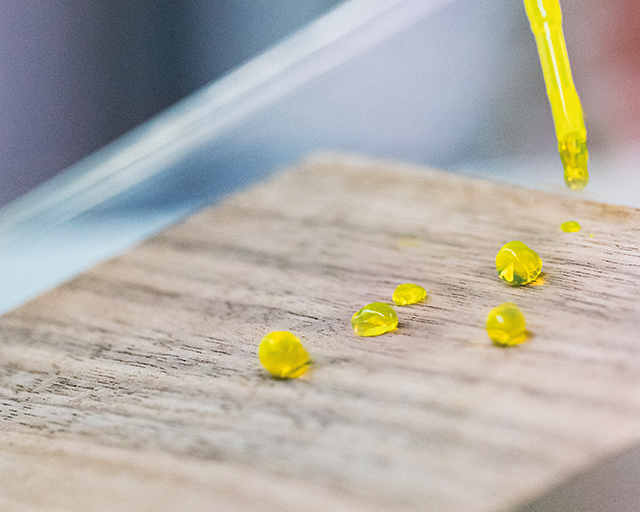

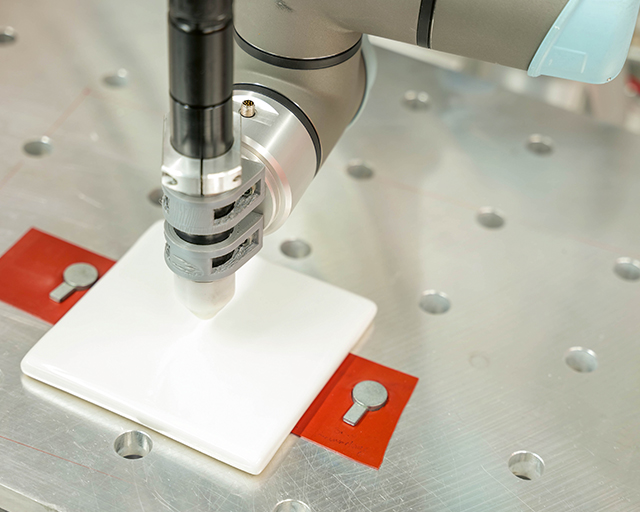

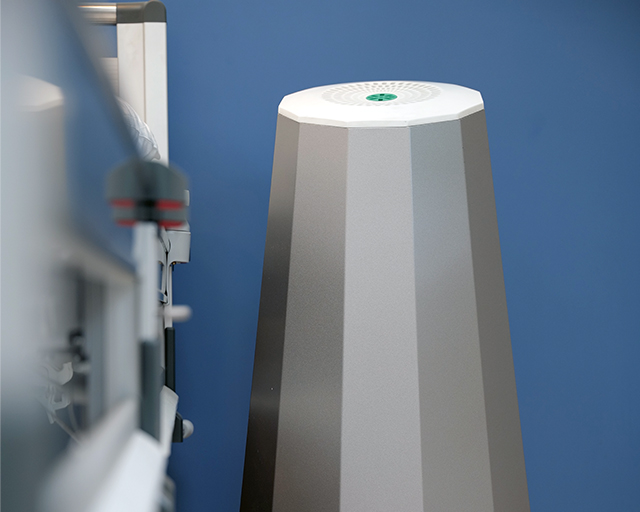

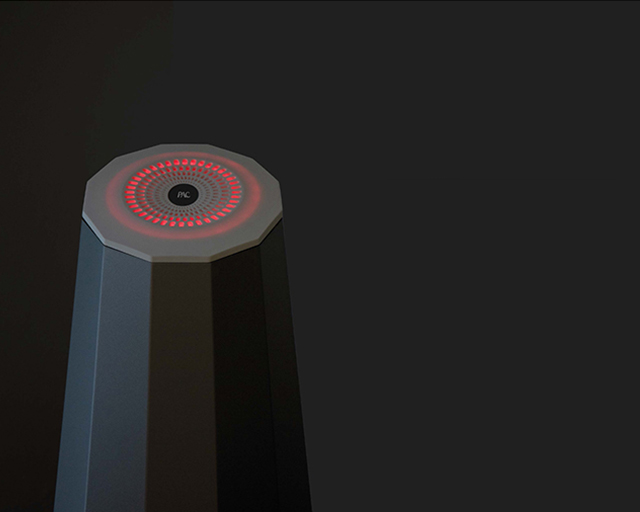

Patient comfort and secure care are not mutually exclusive. This is demonstrated by the Fraunhofer IST, the Institute for Construction Design, Industrial and Health Care Building (IKE) of TU Braunschweig, and the Städtisches Klinikum Braunschweig in the “Patient room of the future”. The real laboratory was constructed in the grounds of the clinic in 2022. Within the framework of the cooperation, application-related issues with a focus on infection prevention and cleaning in normal care are to be addressed. The emphasis is on the development of innovative, practicable technical construction sample solutions, smart materials and surfaces, and future-proof equipment elements and products. In line with the motto “from bedside to bench and back”, new ideas are continuously being implemented in the real laboratory, questions from the hospital’s day-to-day practice are transferred to research, and innovative solutions are tested with regard to their practical suitability in the patient room.

To ensure that the ideas quickly find their way into application, the three research partners are working closely together with various manufacturers. Currently, 20 partners are active in the accompanying industry consortium. Further research projects are initiated on a regular basis, thereby taking into account the needs of neighboring sectors, with a view to maximizing efficiency and effectiveness. Questions which form the focus for the Fraunhofer IST in the “Patient room of the future” are oriented to the following topics:

Resilient surfaces for infection prevention

New cleaning and disinfection systems for surfaces and devices

Recyclability of the utilized materials and processes

Digitalization

”The ‘Patient room of the future‘ is more than just a room with two beds and two showers.”

Dr. Kristina Lachmann, Project Manager