Robot-guided plasma treatments enable the structured modification of the surface chemistry of three-dimensional components. This makes it possible, for example, to control and improve the adhesion of coatings and bondings to surfaces. At the Fraunhofer IST, a corresponding treatment system has been successfully established and tested in order to enable the treatment of application-related components and the investigation of the influence of this treatment.

Robot-guided plasma treatment of 3D surfaces

Possibilities with plasma treatment

With the aid of atmospheric-pressure plasmas, the surfaces of the most diverse materials – such as polymers, ceramics or metals – can be modified. Depending on the process gas, it is possible to etch, roughen, oxidize, reduce, functionalize or coat the surfaces. The surface properties and further processability of workpieces by means of bonding, painting or fusing can be significantly improved through plasma treatment. Contaminations can be removed, and wetting and adhesion can be enhanced. This is already being used intensively in technological applications, particularly on 2D surfaces such as polymer films and plates, and is the current state-of-the-art. A wide variety of plasma sources with varying functional principles and application possibilities are available for this purpose.

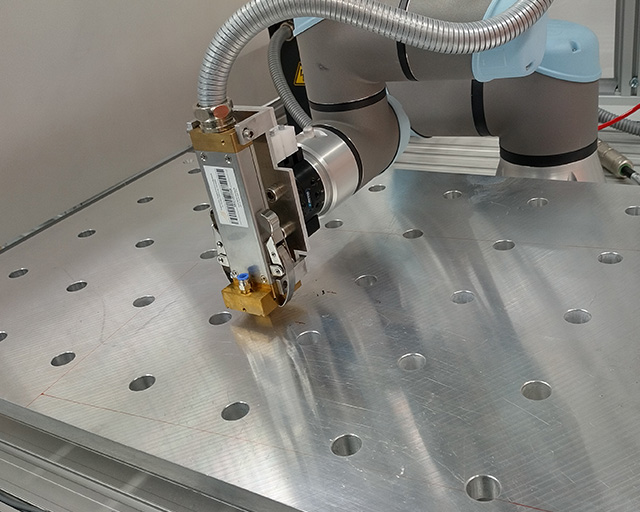

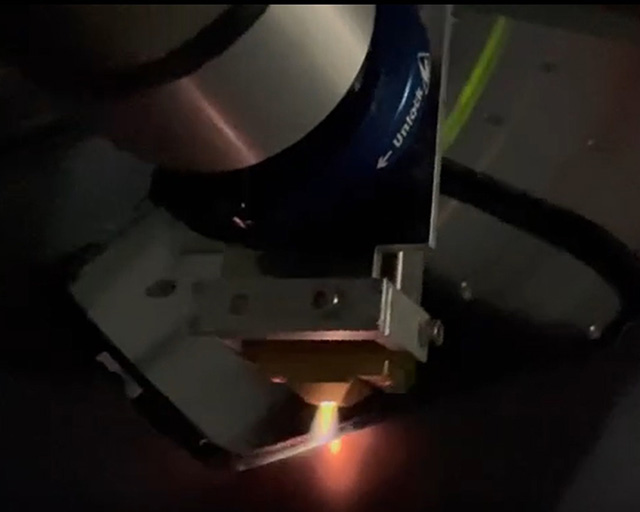

Robot-guided treatment with plasma jets

One interesting type of plasma source is the so-called plasma jet. These generate a jet of ionized and activated gas – plasma – which can treat a highly defined surface area. As a result of the activated gas, the chemical bonds necessary for surface modification can be broken. Plasma jets are particularly suitable for use in robot-guided systems, in order to carry out treatment on spatial components.

At the Fraunhofer IST, an atmospheric-pressure plasma treatment system for medium-sized 3D components (< 50 x 50 x 80 cm³) with robot-guided plasma jet has been constructed. With this system, dielectric and electrically conductive materials can be treated with a nitrogenous plasma. The system features a housing with an extractor, with which harmful process gases can be removed. The modification of the components is performed using a resolution of around 1 cm and a high power density of around 500 W/cm², with treatment speeds of up to 1 m/s. The improvement of, in particular, the adhesion of coatings and bondings on injection-molded polymer surfaces has already been successfully demonstrated with this method.

Outlook

In the future, in addition to cleaning and plasma activation, the Fraunhofer IST will also be increasingly investigating the layer deposition of e.g. adhesion-promoting layers on 3D surfaces. As well as improved automation ability of the processing, the focus will also be directed at the integration of the treatment into specific process chains.