Functional surfaces and coatings in the patient room of the future

Stringent requirements in the patient room of the future

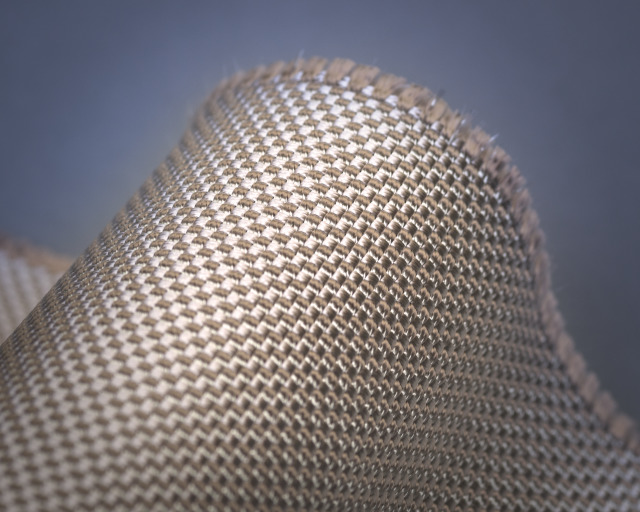

The materials and surfaces in a patient's room must be capable of withstanding high demands. In addition to resistance to everyday mechanical stresses, e.g. of floors or door and window handles, chemical resistance to cleaning agents and disinfectants is also necessary. The scientists at the Fraunhofer IST are therefore working on solutions for the application of functional coatings which are mechanically and chemically stable. Simultaneously, the processes and coating patterns required for this should be as sustainable as possible. One example concerns bio-based coating formers for the production of dirt-repellent surfaces. In this case, natural oils are used as the starting material for a coating that exhibits very good dirt-repellent effects - even as a thin film.

Surface and coating technology for improved protection against infection

Das Fraunhofer IST verfügt über zahlreiche insbesondere The Fraunhofer IST has numerous – in particular gas-phase-based – coating processes at its disposal with which thin films can be produced or surfaces directly modified or altered. Depending on the application, the surfaces are endowed with different functions and properties, e.g. dirt repellency, antifouling, corrosion protection or antimicrobial effectiveness. In order to prevent biofilm formation – and, therefore, antimicrobial contamination – various approaches are possible. In addition to the chemical composition, the topography and film structure can be adjusted in such a way that, for example, adhesion of particles or germs is minimized, which is often the starting point for biofilm formation and, consequently, antimicrobial contamination.