The increasing scarcity of raw materials makes the development of sustainable consumption and production patterns an important goal for the UN. The Fraunhofer IST's contribution to ensuring sustainable consumption and production patterns focuses on:

SDG 12: Sustainable consumption and production patterns

More efficient use of resources

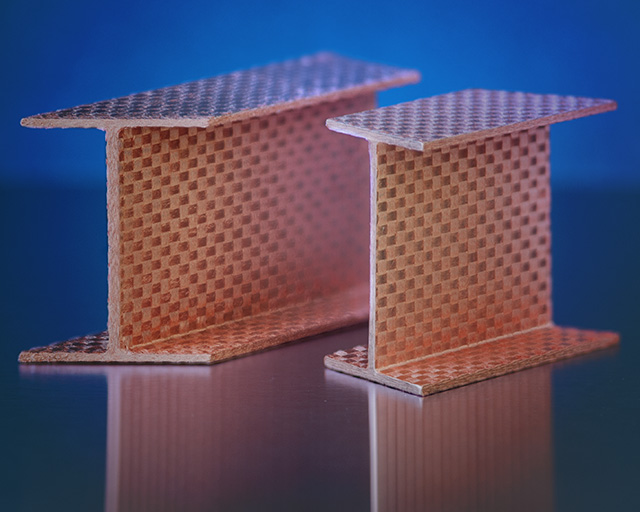

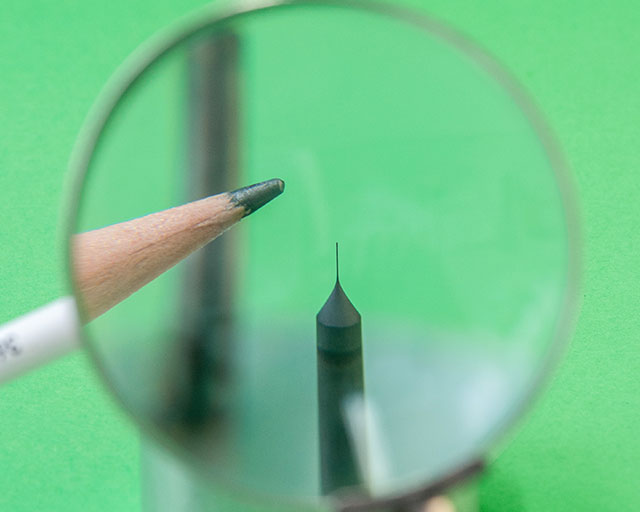

At the Fraunhofer IST, innovative processes and materials are developed which reduce the use of raw materials during production. As an example, combination processes of atmospheric-pressure plasma procedures and electrochemical methods enable a more precise application of materials. Moreover, optimized hard-material and nanostructured film systems for forming, cutting or machining tools extend the service life of diverse facilities, which leads to a more economical and therefore resource-saving production. Furthermore, the development of new materials also plays an important role. By combining existing films and basic bodies, materials with new properties are realized at the institute.

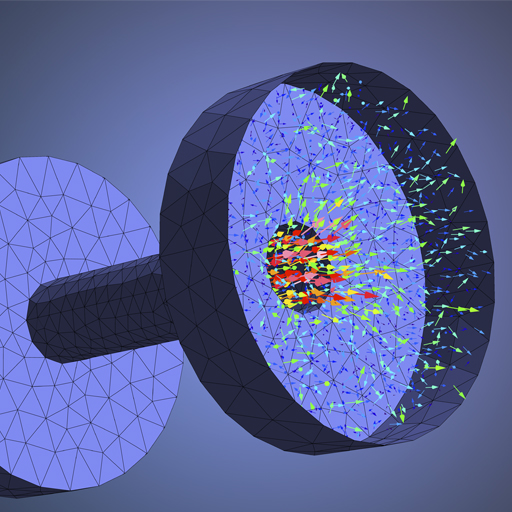

Simulation-supported production

A further thematic focus at the Fraunhofer IST is presented by the field of simulation and modeling. Simulations enable ever-shorter development times; highly efficient production chains, for example, can be realized through the model-based design and implementation of coating processes. Furthermore, by coupling specific simulation models, interactions between products and production systems become evaluable, thereby enabling savings potentials to be made visible. The development of cyber-physical production systems enables a more sustainable production design. Through the use of so-called “digital twins”, design alternatives can be analyzed in real time.

Less waste

Recycling is an important keyword for the work at the Fraunhofer IST. In order to reduce the amount of waste and simultaneously promote the more environmentally friendly handling of chemicals, the institute is carrying out work in the fields of material development and substitution. Examples include the development of alternative materials and production processes, with the aim of replacing diverse environmentally harmful substances such as indium tin oxide (ITO) or chromium (VI).