Digital economy: Simulation solutions in surface technology

Industry 4.0 in surface technology and digitalization of production lines

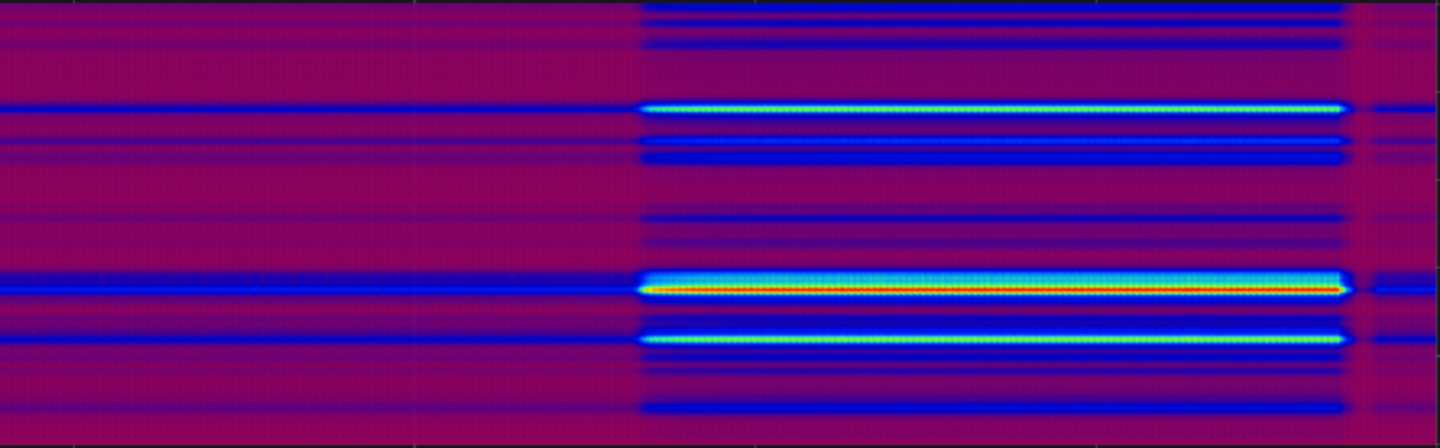

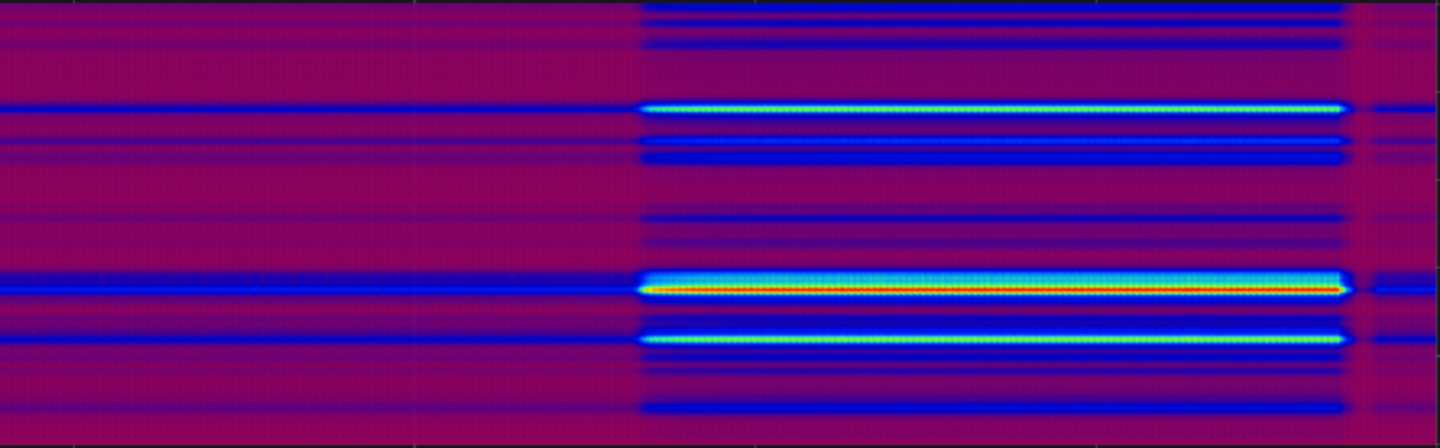

The continuously increasing demands on coating products with respect to efficiency, reproducibility and sustainability call for systematic acquisition of product and process data. Digital Twins make use of these data in order to identify the origins for process drifts or defects and to reveal complex interdependencies between different process steps and can thus aid in process optimization in surface technology. While in thin film technology, digital twins exist for selected sub-processes, a digitalization of complete process lines is nowadays still a big challenge.

Contribution of Fraunhofer IST for digitalization in thin film technology

Fraunhofer IST offers simulation codes in the field of thin film technology in combination with long-term experience from real coating processes and film analytics. Thus, all prerequisites to create experimentally validated simulation solutions are available in place. Based on these tools we offer simulation case studies for process optimization or knowledge transfer by software licensing and hands-on training workshops. Furthermore, we offer to support the digitalization of production lines via sensor data acquisition, conception and implementation of databases. Additionally, we offer support in the field of high performance computing hardware and cloud computing.

Holistic digital process chain – from material to high-tech product

At the Fraunhofer Institute for Surface Engineering and Thin Films IST, we keep an eye on the entire product life cycle and develop sustainable products and associated production systems. Digitization, networking and automation are the keys to a holistic design of process chains and their embedding in production systems. Central to our work is a profound understanding of the relationships between the process parameters, the resulting structure of thin films and surfaces, and the final properties of the product. Inline and laboratory analytics create the foundation for this and provide important data for simulation-based approaches, e.g. for a simulation of layer growth or new data-driven approaches based on machine learning.