Process automation with MOCCA+®

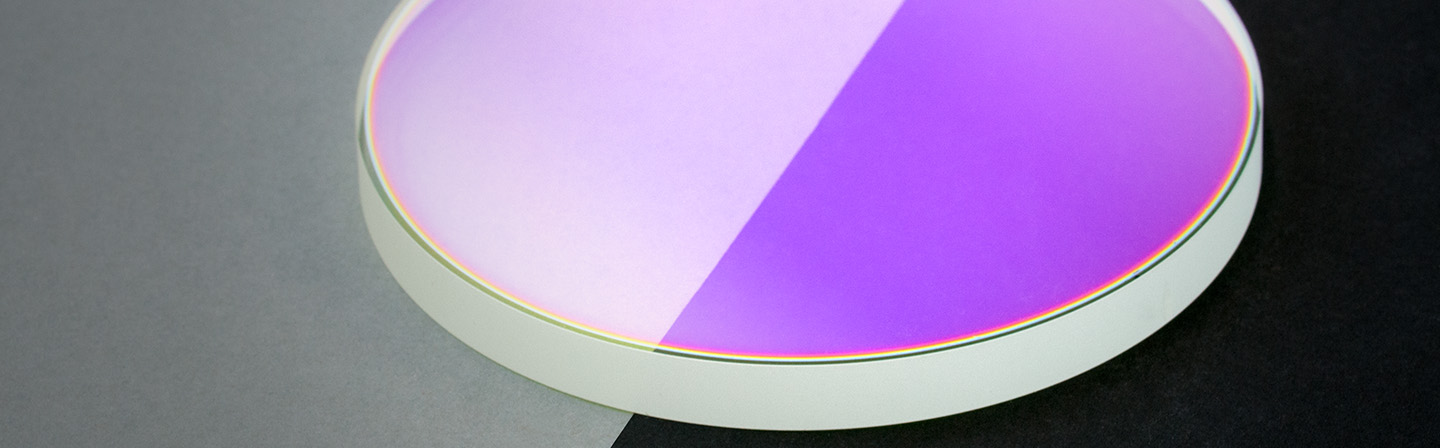

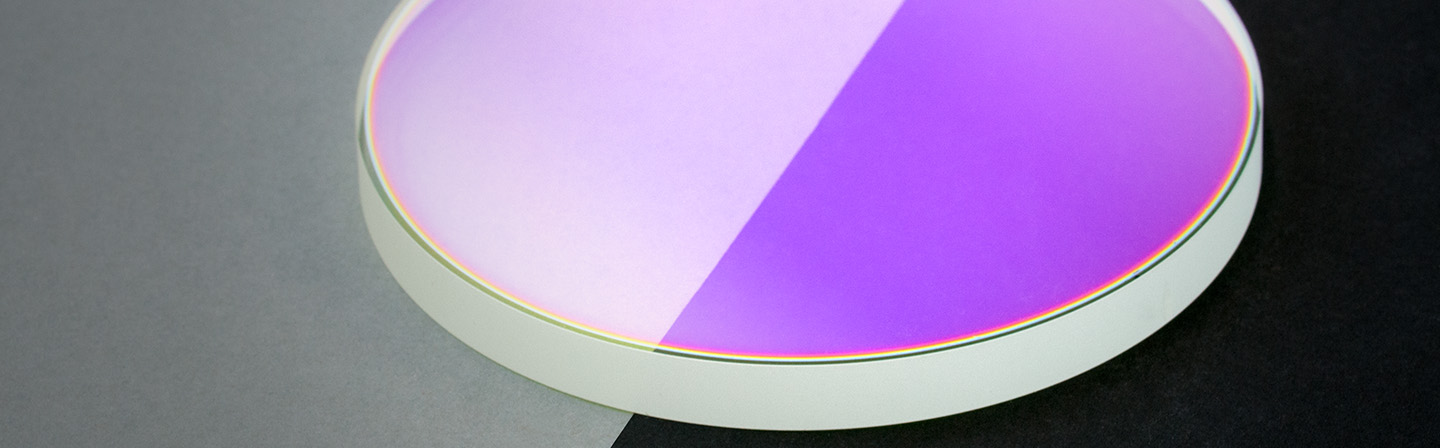

The complexity and product diversity of industry-relevant optical systems is increasing continuously. With advancing digitization, flexible product changes are becoming a necessity. Users, including those in the thin-film industry, expect an ever higher degree of automation of the systems. With the EOSS® technology (Enhanced Optical Sputtering System), the Fraunhofer IST offers the possibility of flexible production of optical thin-film systems of the highest quality. The MOCCA+® software (Modular Optical Coating Control Application) developed at the Fraunhofer IST is capable not only of optical broadband-monitoring of the individual layers of a filter but also of controlling the EOSS® facility. Between the individual coating tasks, intervention by the user is no longer necessary, as the exchange of the substrates is performed automatically.

Production planning

Producers of optical components and their coatings are increasingly demanding the possibility of planning many coating batches in succession, for example in order to be able to continue production throughout the weekend. The production planning integrated in the MOCCA+® software is capable of taking over this task. For this purpose, the system operator defines the substrate types to be coated for each individual process in a visual interface - simply and conveniently by drag-and-drop. Before the process starts, the system determines whether the defined substrate types are available in the required quantities in the process chamber and the magazine chamber. If this is the case, the coated substrates are automatically discharged and new uncoated substrates are transferred to the process chamber.

The actual coating process takes place under high vacuum. Through the use of a separate magazine chamber, ventilation is, however, also possible during an ongoing process. As a result, coated substrates can be removed from the magazine chamber at any time, and uncoated substrates can be inserted for the next planned processes. Once the substrates have been successfully exchanged, the magazine is then pumped out again. In order to ensure the uninterrupted completion of several processes in succession, the operator therefore only needs to ensure that the magazine is ready again at the end of the current coating process.

Process reliability

MOCCA+® is directly linked to the PLC (programmable logic controller), the main component for the control of the coating facility. This enables a very fast reaction in the event of, for example, error messages and therefore significantly increases process reliability. By avoiding the failure of entire coating batches, both time and material can be saved. MOCCA+® is able to stop the coating process if a critical deviation from the expected coating process is detected. Furthermore, the PLC pauses the process as soon as one of the system components deviates from its specified parameter range. As a result of these quick interruptions, undesirable coating conditions can be avoided. Once the operator has resolved the cause of the problem, coating can continue.

In the event of a power failure, this is also communicated to MOCCA+® and the process and the PC can be shut down in an orderly manner while the UPS (uninterruptible power supply) is still active. This prevents data loss and, in many cases, even enables subsequent successful coating.

As a result of the modular structure of the MOCCA+® software, it is also possible to perform adaptations on other types of coating facilities. Contact us and we can discuss the possibilities together.

This article is part of the Annual Report 2021.