Artificial intelligence for the automation of services in distributed network infrastructures

Challenge

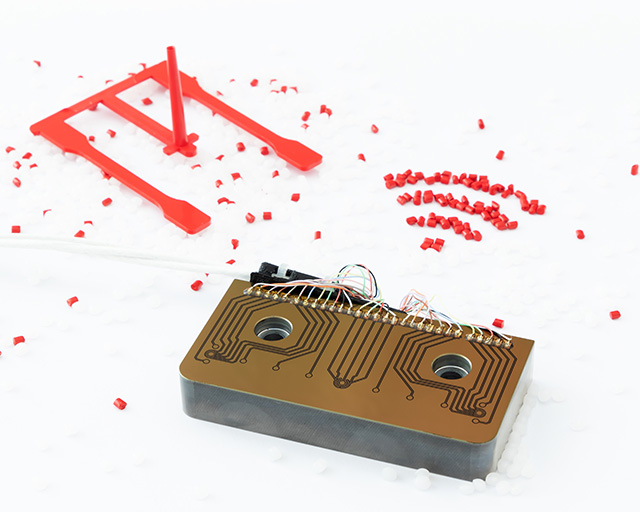

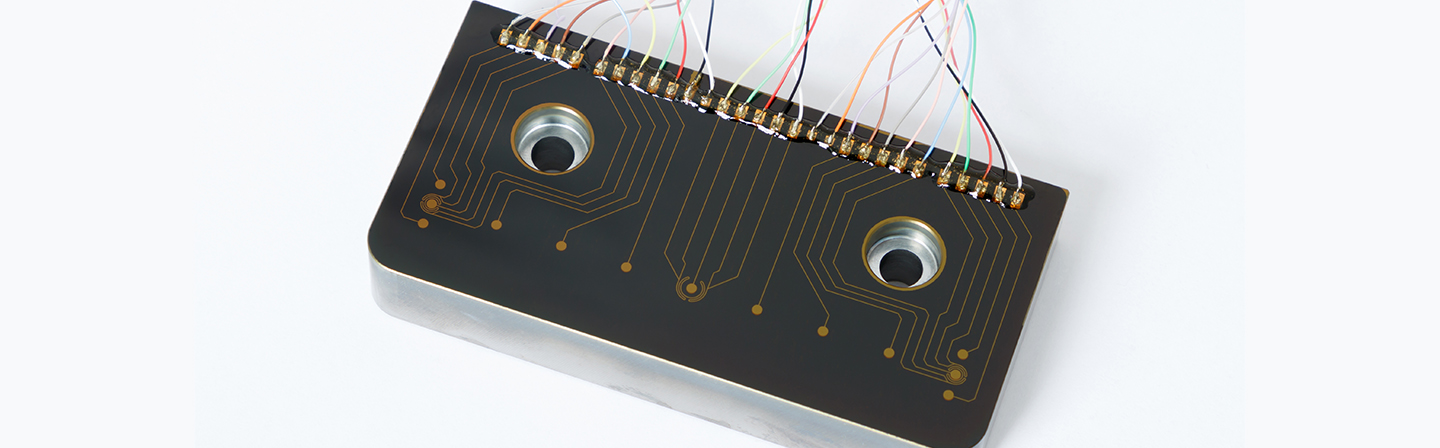

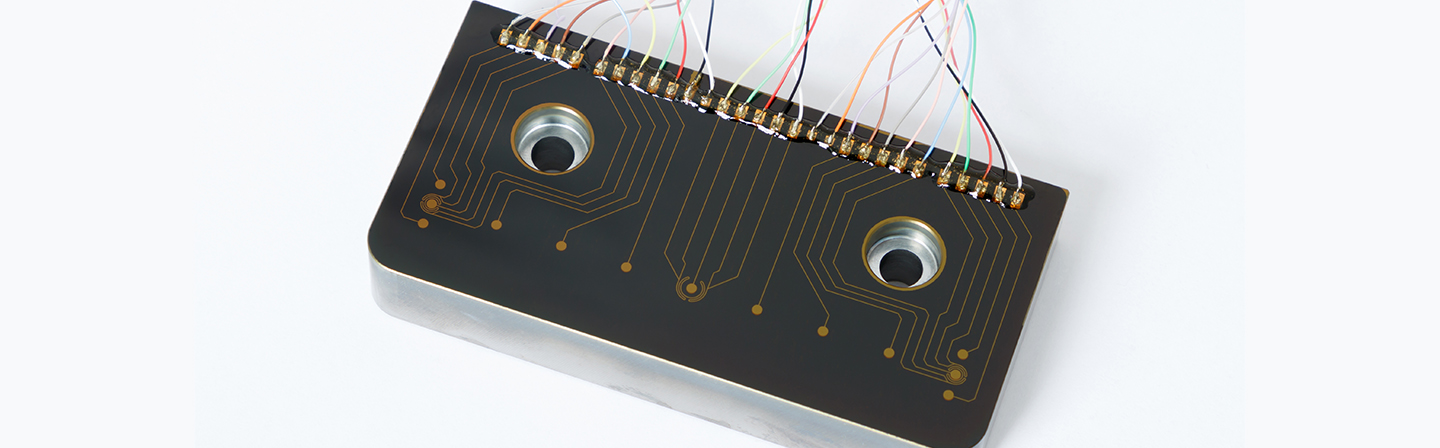

Digitalization is of enormous importance, and developments such as robotics and Industry 4.0 will continue to exert a significant influence on our lives. In the “ANIARA” project, the Fraunhofer IST is working on the development and interconnection of intelligent thin-film sensors for automated, wireless data exchange on the basis of concrete use cases in the context of production technology.

Solution

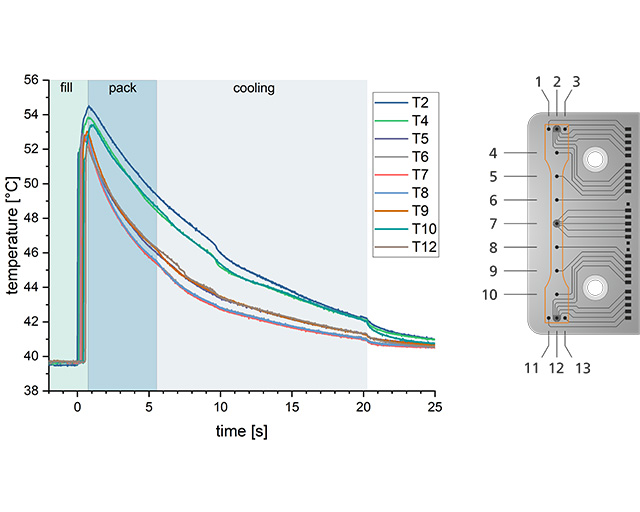

ANIARA brings together three fields of technology: Communication networks and technologies for 5G and prospectively 6G, usage-related data centers, and artificial intelligence (AI). The Fraunhofer IST will thereby develop real-time-capable sensor systems which can be integrated into existing infrastructures and utilized for data analysis with AI algorithms. By means of automated error detection and the derivation of virtual product properties, optimal operating strategies are to be developed and the entire process chain monitored.

Added value

The results of the research project enable a systematic and goal-oriented development and interconnection of real-time-capable thin-film sensors to automated network and communication structures. Consequently, the generated sensor and measurement data can be used more efficiently and comprehensively in the future, including across different locations.