Coatings for aluminum and magnesium die-casting tools

In the industrial series production of aluminum and magnesium components, die casting plays an important role. With this technology, parts such as casings or structural components can be produced in various dimensions in large quantities. They are characterized by a favorable strength-to-weight ratio and are therefore suitable for energy-efficient mobility and drive applications. In recent years, the demands placed on these components as regards their geometry or the small draft angles have increased – and, consequently, the demands on the molds as well. Both the service life and the wear behavior of the tools can be increased enormously through targeted surface technology, thereby supporting efficient and economical production.

Highly stressed tools

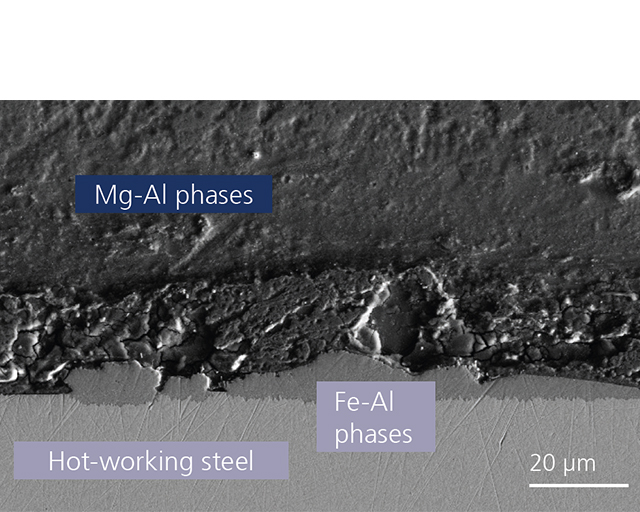

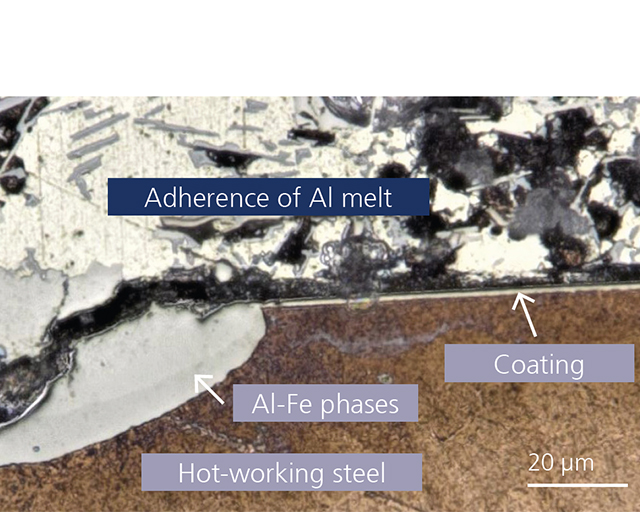

Tools for the die-casting of aluminum and magnesium are subject to high stresses and often fail after only short periods of operation. One potential cause is geometry deviations, which can be induced by a multitude of wear mechanisms. In addition to chemical attack by the molten metal, it is common to adhere on the die surface and severe leaching can occur in areas of high flow velocity due to particle erosion on the die surface. The resulting topography changes can cause massive amounts of adhesion. In combination with thermal stress, this can lead to chemical attack. Furthermore, cracks can form due to the high thermal-shock load.

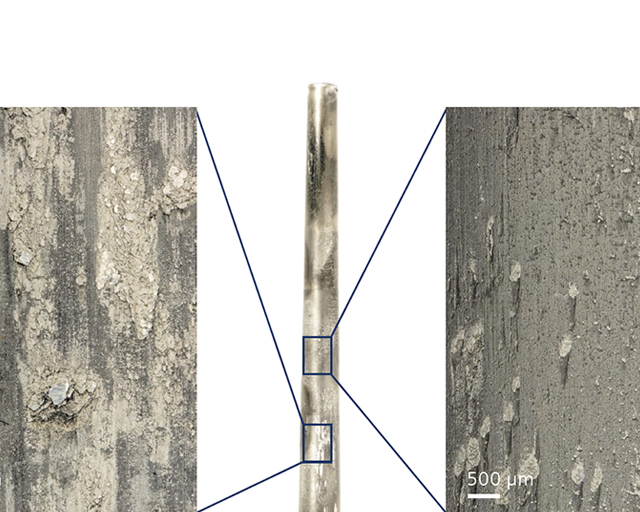

Extended tool life

The shorter the downtime and set-up times, the greater the economic benefit of a plant in production operation. At the Fraunhofer IST, the process chain for surface treatment was therefore adapted to the loads. By combining and optimizing blast treatment, nitriding and coating, it was possible to achieve tool-life increases of up to 500 percent for the aluminum die-casting tools. During the development described above, knowledge was gained which constitutes an important basis for the optimization of surfaces in accordance with the incurred stresses – also for other applications such as aluminum permanent-mold casting, gravity die-casting and magnesium die-casting.

Are you looking for support in the wear-protection treatment of die-casting tools which are optimally adapted to your products? With the process chain for wear-protection treatment developed at the Fraunhofer IST, considerable increases in performance can be achieved. This has been substantiated for small tools, cores and even large tools in series operation. Treatments, coatings and process chains are specifically adapted to the geometry and application field of the tools. Contact us!