Sealless rolling bearings that can be used under media lubrication possess high potential for utilization in energy-efficient and resource-saving applications. Standard rolling-bearing materials are, however, of very limited use under these combined stresses of corrosion and wear. A remedy can be offered through edge-zone treatment by means of low-temperature plasma nitriding. The aim of the POSEIDON-II project, on which the Fraunhofer IST worked in collaboration with project partners, was to optimize the material development initiated in the predecessor project POSEIDON-I and to provide rolling-bearing steels capable of withstanding stresses with regard to mechanical, tribological and chemical-corrosive boundary conditions.

Treatment possibilities for components subjected to tribocorrosive stresses

Challenges

In tribocorrosive environments, both corrosion and wear – and the combination of both – play a significant role. In these cases, standard materials exhibit either good corrosion resistance or good wear resistance. For materials to remain resistant within this complex tribological system with corrosion attack, both requirements – high corrosion resistance as well as wear resistance – must, however, be fulfilled. In addition to the corresponding development of treatment solutions on a laboratory scale, the transfer to industrial batch treatment of the rolling bearings is also essential in order to ensure the economic viability of production.

Solution approach

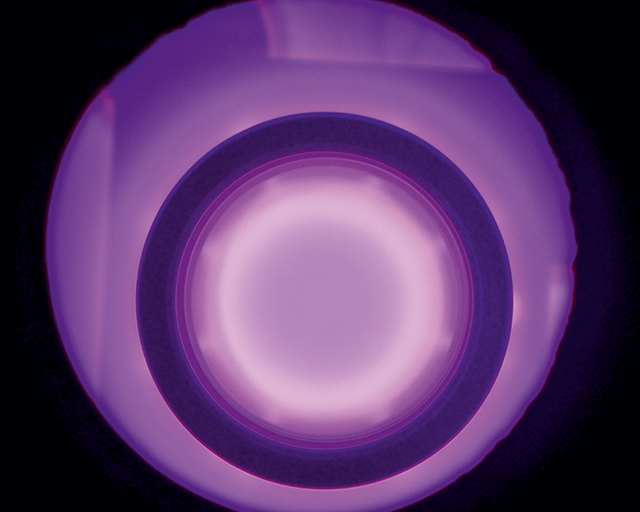

One possibility, through which stainless steels can withstand these stresses, is edge-layer treatment by means of low-temperature plasma nitriding. In this process, nitrogen is dissolved in the interstitials of the material, resulting in an increase in hardness. The advantage of this process compared to a conventional nitriding process is that the low treatment temperature prevents the precipitation of chromium nitrides, which maintains or even improves the corrosion resistance of the base material. Investigations conducted by the project partner Ruhr University Bochum showed an improvement in tribocorrosion resistance of up to 70% for the edge zones produced at the Fraunhofer IST.

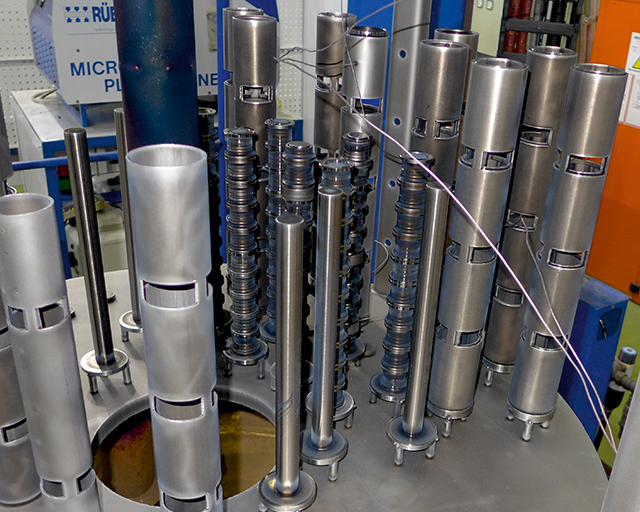

Process transfer to industrial scale

In order to be able to implement the advantages of this type of treatment in the application, it is necessary – from an economic point of view – to treat large quantities. With the aim of making the results usable on an industrial scale, investigations were therefore conducted regarding the transfer of process control to industrial scales. Knowledge was thereby gained concerning the homogenization of the process with regard to plasma conditions and temperature and gas distribution, and recommendations for batching were derived.

The project

The described work was undertaken within the framework of the joint project “POSEIDON-II”, funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK), as part of the 6th Energieforschungsprogramm (energy research program). The Fraunhofer IST is engaged in the sub-project “Randschichtmodifikation des Grundmateriales, Duplexbehandlungen” (Edge-zone modification of the base material, duplex treatments) (FKZ 03ET1477D).

Outlook

Through this project, a contribution has been made towards the industrial utilization of edge-layer treatment processes. The findings provide the foundation for further optimization and, in addition, demonstrate the potential for application in other industrial sectors. Moreover, the topic field of tribocorrosion, with its complex interrelationships, offers a wide range of additional research opportunities that can contribute towards a better understanding of this system.