Energy efficiency through increased service life of bearings under tribocorrosive operating conditions

Challenge

Seal-less rolling bearings that can be used under media lubrication possess a high potential for utilization in energy-efficient and resource-saving applications. Under these highly tribocorrosive conditions, standard rolling-bearing materials can only be used to a very limited extent.

Solution

Within the framework of the BMWi project, cost-effective novel steels on an austenitic (carnite CN0.96) and martensitic (M340, MNS) basis are optimized by means of edge-layer treatments using adapted low-temperature plasma-diffusion treatment. As a result, zones of expanded austenite and expanded martensite are created in the vicinity of the edge, thereby enabling an increase in hardness whilst also improving corrosion resistance in media-lubricated applications.

Added value

As an industrially scalable process, low-temperature plasma nitriding is capable of enhancing the properties of cost-effective martensitic and austenitic steel materials. For the respective materials, reference processes were determined which achieve the target definition for hardness and thickness as well as corrosion properties of the edge layers. In order to implement the results in an industrial process, investigations are being conducted which will enable the very positive results to be exploited.

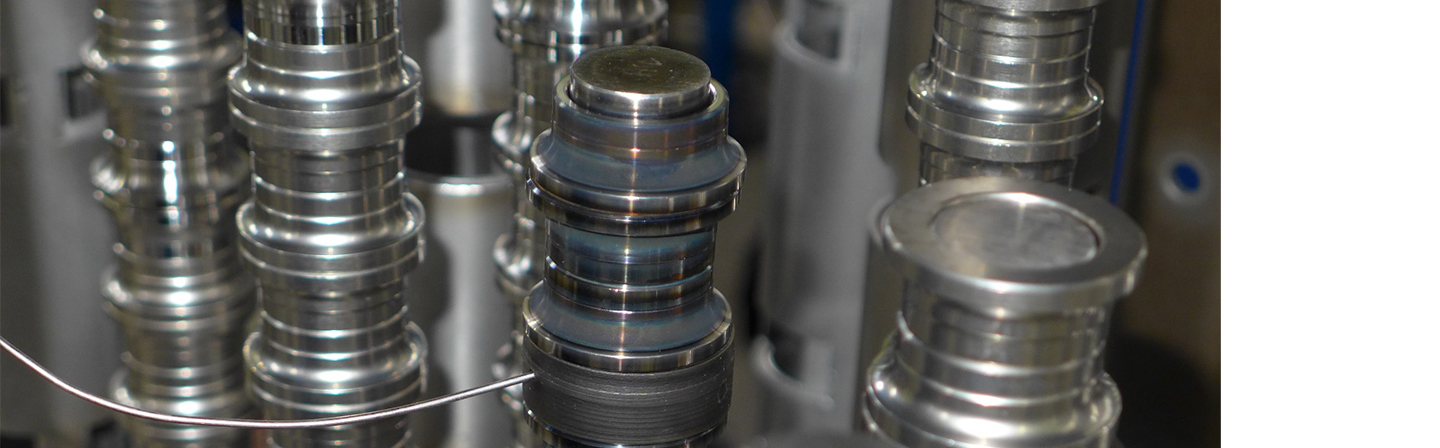

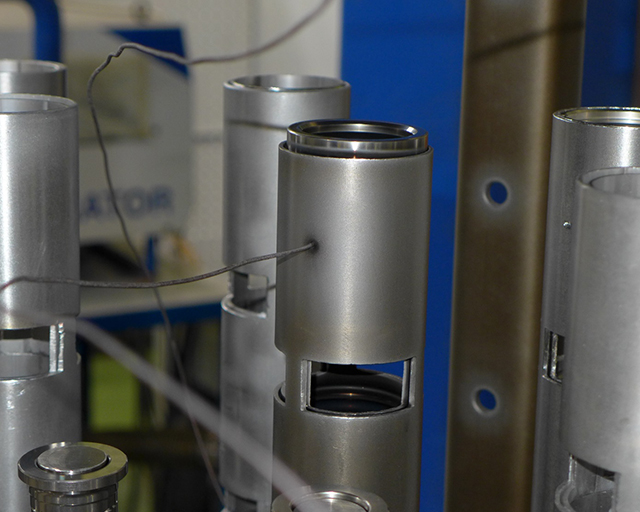

Insights into the project

Funding reference

The joint project POSEIDON II is funded by the BMWi within the framework of the German government's 6th energy research program “Forschung für eine umweltschonende, zuverlässige und bezahlbare Energieversorgung“ (Research for an environmentally friendly, reliable and affordable energy supply). The Fraunhofer IST is undertaking the sub-project “Randschichtmodifikation des Grundmateriales, Duplexbehandlungen“ (Edge-layer modification of the base material, duplex treatments) (FKZ 03ET1477D).