Adapted surfaces for all application scenarios

Versatile treatment possibilities qualify surfaces for all types of loading and application cases

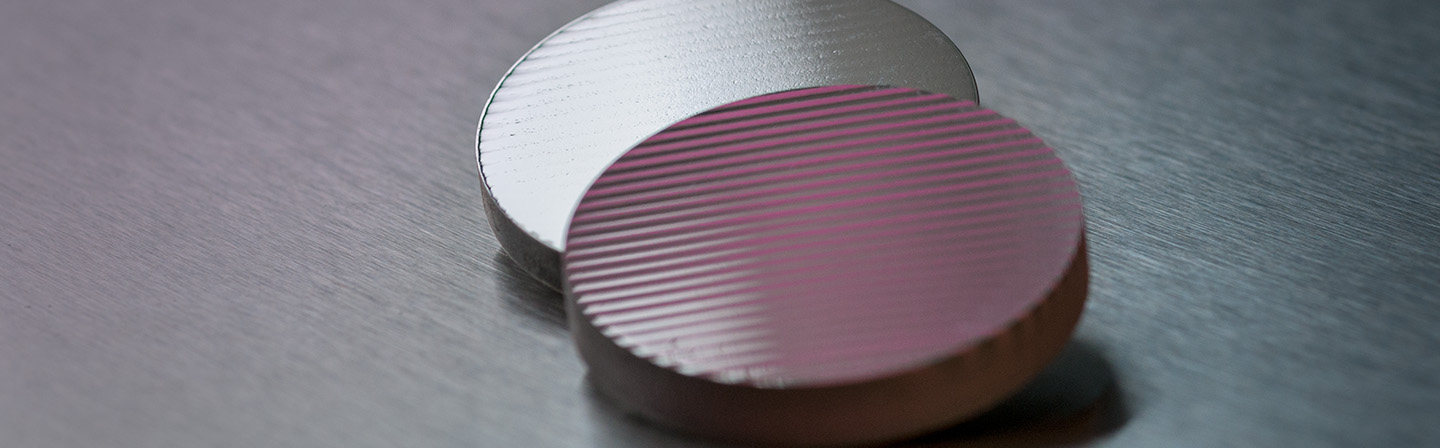

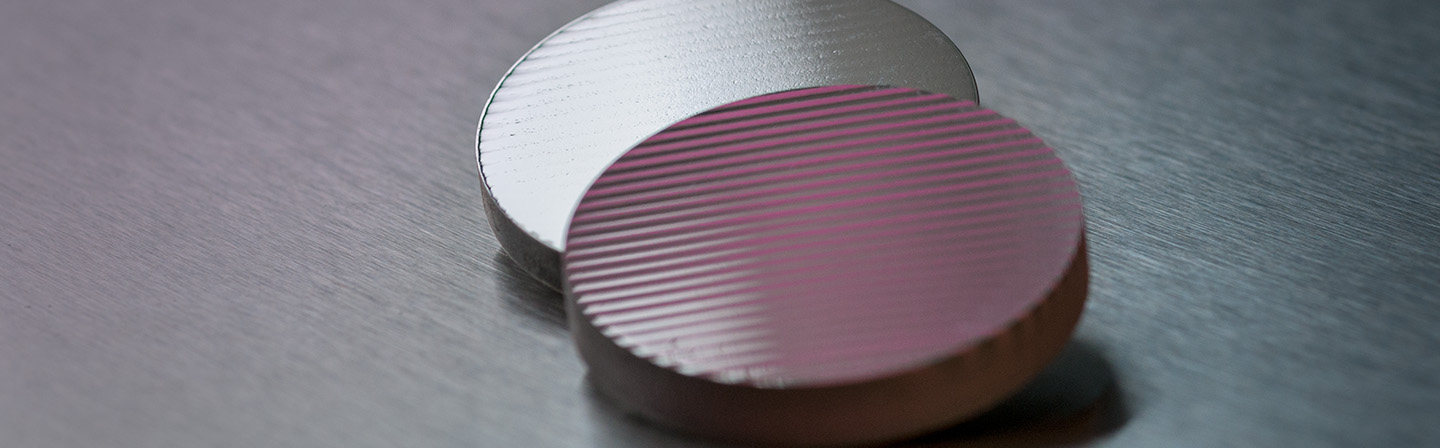

At the Fraunhofer IST, the most diverse tools are available for the production of resilient and highly functional surfaces. Once the application has been analyzed in detail, the optimum solution is created through the combination of mechanical, thermal and plasma-technology treatment processes. Defined roughness, extreme smoothness, thermal and plasma-driven diffusion treatments and, of course, coatings interact to increase the usage value of the surfaces and, in many cases, make the application possible in the first place.

New and efficient production and application processes through adapted surfaces

What requirements are placed on the component or tool and what must its surface be capable of? Be it, for example, high wear resistance, low friction, pronounced wettability or resistance to disintegration at high temperatures: Through the combination of suitable treatment processes and a goal-oriented experimental design, the individual requirements are met. For this purpose, we have procedures for mechanical surface treatment such as blasting, polishing, edge-layer treatment (diffusion process) and coating at our disposal.