EOSS® – Production of optical coatings of the highest quality and with high throughput is no contradiction in terms

Across precision optics and applications in defense and security, environmental monitoring, smart farming, laser protection and many more, ultra‑precision optical coatings on optical assemblies are key to achieving tailored reflection, transmission, polarization, scattering, and color—enabled at industrial scale by our EOSS® platforms OPTA X and FHR.Star-EOSS® for producing these exacting optical filters.

Deposition of optical interference filters

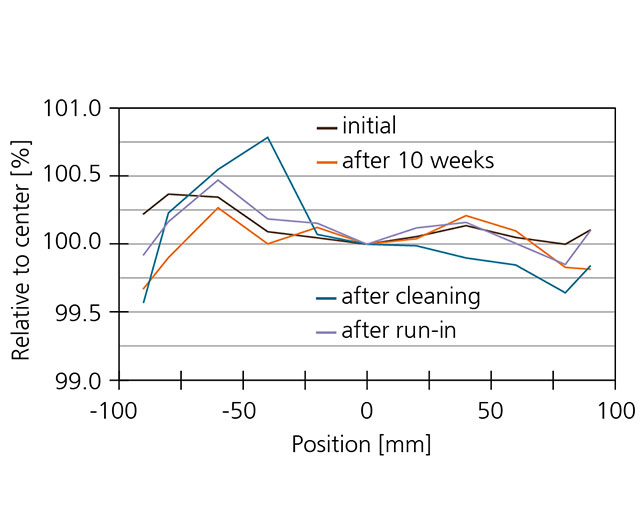

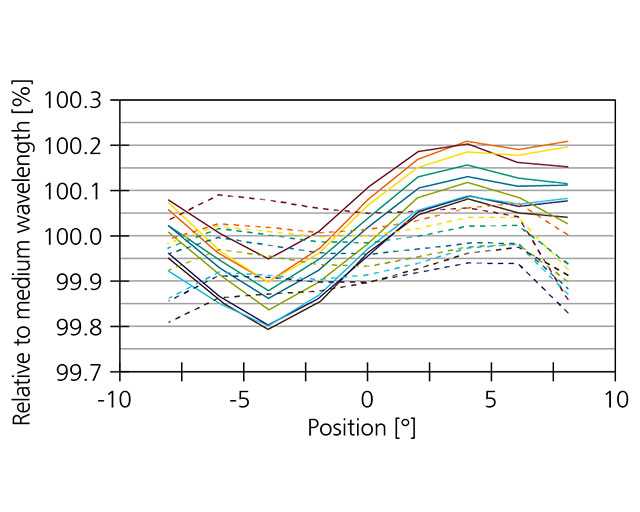

Interference filters for modern applications in the consumer sector as well as in special applications consist of highly complicated layer designs with different individual thicknesses. These must be deposited with both extreme precision and low defect rates. For the user, the stability of the process and the adjusted layer properties are also of great importance for productivity. This is largely determined by the uniformity of the coating thickness over the component, because this has a direct influence on the spectral characteristics which determine the function.

Innovative coating platform: The EOSS®-coating concept

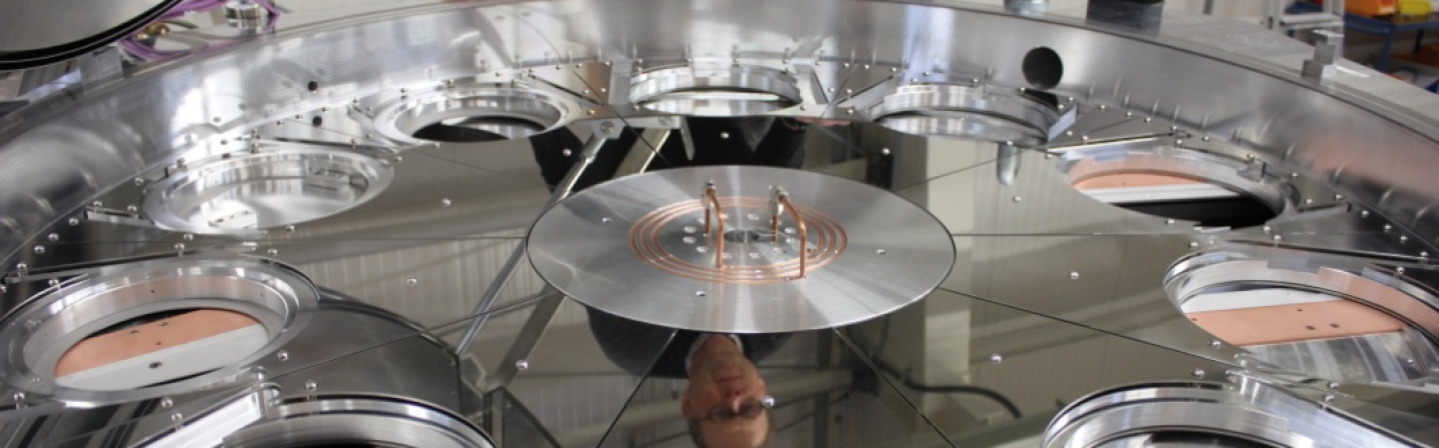

The Fraunhofer IST uses magnetron sputtering technology for the production of optical coatings. In the EOSS® coating concept (EOSS® stands for "Enhanced Optical Sputtering System"), the substrates are arranged on a rapidly rotating turntable. Deposition takes place from the metallic or sub-stoichiometric rotating tube target and complete oxidation takes place using a plasma source. The high gas-chamber separation means that it is possible to achieve a permanently stable process without feedback control. Material properties are replicated just as reliably as the layer-thickness distribution over very long periods of weeks and months without readjustment. The productivity of the coating facilities of our customers can be enhanced through our MOCCA+® software, which not only allows optical in-situ monitoring, but can also adaptively control the coating process. The technology is patented by Fraunhofer IST and licensed to equipment manufacturers. The machines FHR.Star-EOSS® and OPTA X are both based on the EOSS® concept.

Both the EOSS® system platform and the MOCCA+® control software are continuously developed. The latest generation of this platform enables simultaneous double-sided coating, with optical in-situ monitoring from both sides via MOCCA+®. It further provides improved in-situ adjustability of the thickness distribution, allowing fine tuning at the per-mille level. Stable deposition of stacks exceeding 50 µm total thickness and comprising many hundreds of individual layers is achieved with excellent properties, while highly productive runs with few but extremely precise layers are equally supported. Material capability now includes coatings composed of up to three different materials (including a-Si:H) and metal–dielectric designs. This latest generation of the EOSS® platform is the basis of the OPTA X coating machine.

Industrial benefit

By taking a holistic view of the entire process chain and the system characteristics of your tools and components, we engineer application-specific, load‑optimized optical coatings and filters. Our EOSS® platform– licensed to equipment manufacturers – enable industrial‑scale production of novel, highly sophisticated optical coatings with outstanding process stability, repeatability, and yield. We complement this with expert support and demonstration coatings – please contact us to discuss your application.

”With the EOSS®, we are able to realize many things that seemed impossible 10 years ago. Today, we are working on the further development of this innovative technology, where digitalization is playing an increasingly important role.”

Dipl.-Phys. Stefan Bruns, Senior Scientist