Magnetron sputtering – a newly discovered technology for the deposition of high-precision optical coatings on 3D components

Challenge

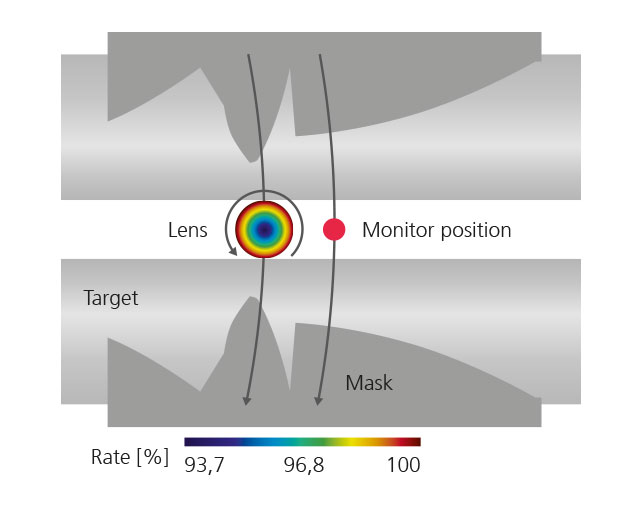

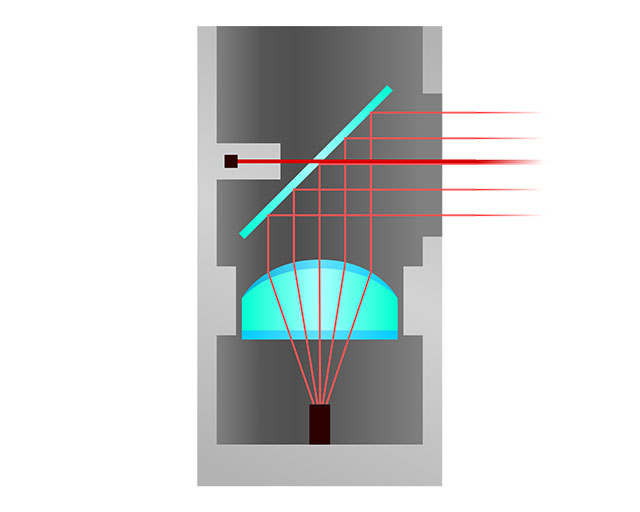

Future applications will require far more complicated coatings that can no longer be achieved through classic processes. Magnetron sputtering offers excellent layer quality; the desired layer distributions are, however, not achieved. The EPIC-Lens project is exploring possibilities for the intelligent control and monitoring of coating distributions.

Solution

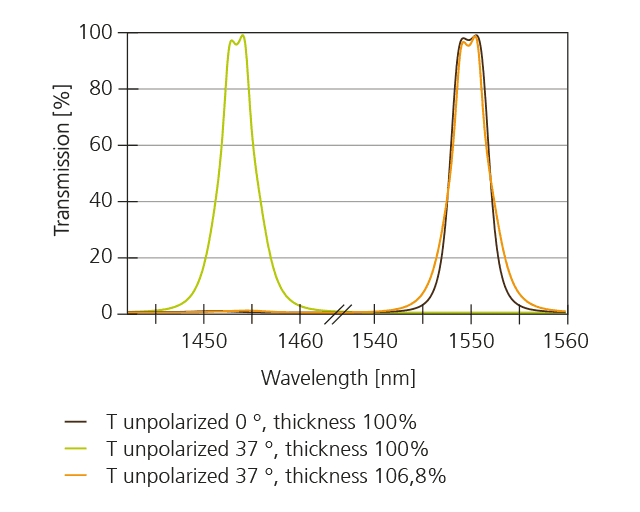

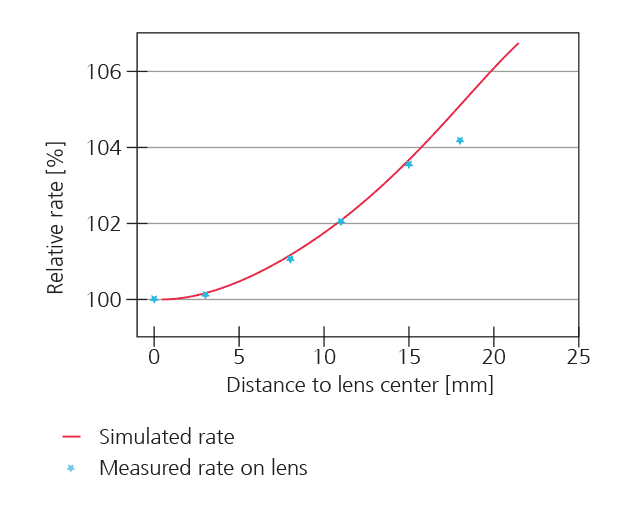

The problem was solved by developing a technology with which arbitrary layer-thickness gradients can be deposited on 2D and 3D components. In order to achieve this, intelligent, automated control of the coating process was undertaken in combination with appropriate in-situ monitoring and control of the coating.

Added value

As a result, more precise gradient layers can be created on planar and curved surfaces with the desired optical function. In subsequent steps, the technology is being transferred into production engineering so that rapid industrial implementation can take place.