Narrow IR bandpass filter on three-dimensional surfaces

So-called LIDAR (light detection and ranging) systems for distance measurement play an important role not only in the automotive industry, e.g. for autonomous driving, but are also essential in the aerospace industry. Here they provide the data required for a space capsule to dock precisely with a satellite station. In order to prevent errors caused by interfering light, e.g. from the sun, a narrow-band infrared bandpass filter (IR bandpass filter) with wide blocking is placed in front of the actual optics. The aim is the development of more compact and, above all, lighter systems in the future. The Fraunhofer Institute for Surface Engineering and Thin Films IST is providing a building block for this purpose through the development of a process which will enable the direct deposition of a bandpass filter on the lens.

The challenge

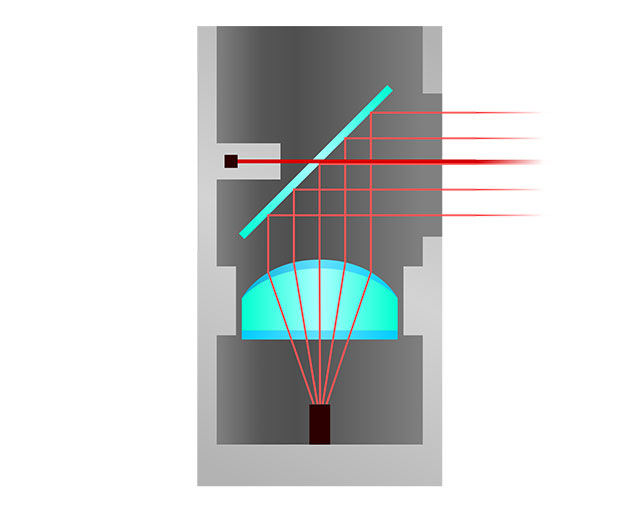

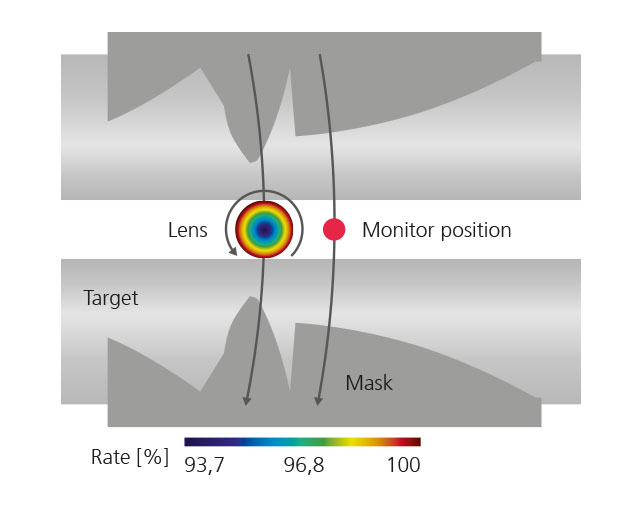

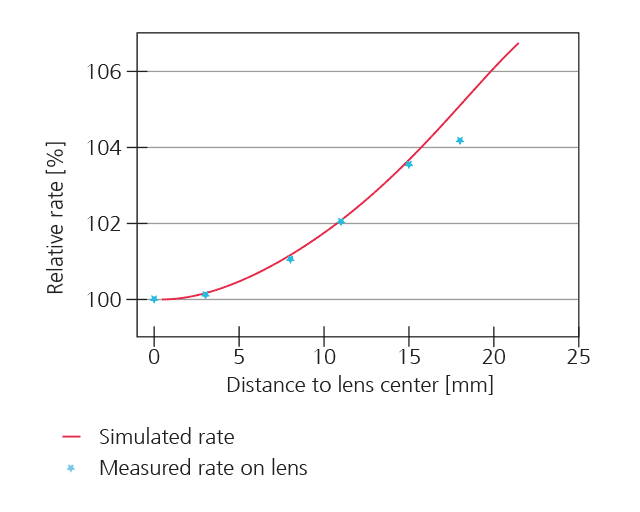

For the production of narrow IR bandpass filters with wide blocking, a complex system consisting of a multitude of individual layers is deposited with high precision in the EOSS® sputtering system at the Fraunhofer IST. Deposition on three-dimensional surfaces such as aspherical lenses thereby poses a major technical challenge, as the coating rate depends heavily on the distance and angle of the coating surface relative to the coating source.

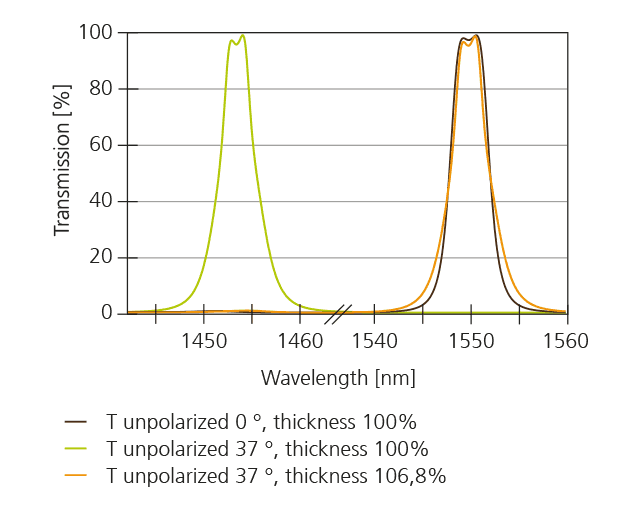

Without corrective measures, this results in the coating of a plano-convex lens being thicker in its center than at the edges. Furthermore, the angle of incidence also changes depending on the position on the lens. Both effects - the decreasing layer thickness towards the edge of the lens and the increasing angle of incidence - intensify each other mutually and shift the bandpass to smaller wavelengths (see adjacent upper graphic).

The Fraunhofer IST solution

In order to compensate for both negative effects, a homogeneous coating of the three-dimensional surface alone - e. g. by means of the ALD process (atomic layer deposition) - is not sufficient. For an ideal compensation, a layer thickness gradient is necessary in which the thickness towards the edge of the lens increases in such a way that the shifting of the bandpass is also corrected through the increasing angle of incidence. For this purpose, a process was developed at the Fraunhofer IST with which the optical filters can be precisely deposited on a plane/convex aspherical lens with a diameter of 50 mm by means of magnetron sputtering.

The central wavelength of the bandpass lies at 1550 nm. For the suppression of interfering light, the filter should exhibit blocking from 400 to 1800 nm. This very wide blocking of the filter system is achieved with two differing layer designs: Firstly, the plane rear side of the lens is homogeneously coated with a blocker in the form of a longpass, and secondly, a bandpass with a gradient aperture is precisely deposited on the convex side. The necessary layer thickness.

Outlook

Following the successful development of the process, plans have been made to deposit the complete narrow IR bandpass filter with wide blocking onto the lens and to test it in the LIDAR system.

The project

The narrow IR bandpass filter on a plano-convex aspherical lens with a diameter of 50 mm for a LIDAR application was developed within the framework of the BMBF research project “EPIC Lens” (FKZ 13N14583).

This article is part of the annual report 2019.