EPMA-Analysis of thin films: Film thickness and composition

The chemical composition and thickness of thin coatings are often the most important parameters determining the function of a film. Quality assurance of these parameters is therefore essential, during both development and production. Electron Probe Micro Analysis (EPMA) is a versatile method for the characterization of thin films with thicknesses ranging from nanometers to millimeters. This multilayer analysis allows the non-destructive determination of the chemical composition and, in the case of films in the sub-micrometer range, also of the film thicknesses - with high accuracy and detection sensitivity.

The measuring principle

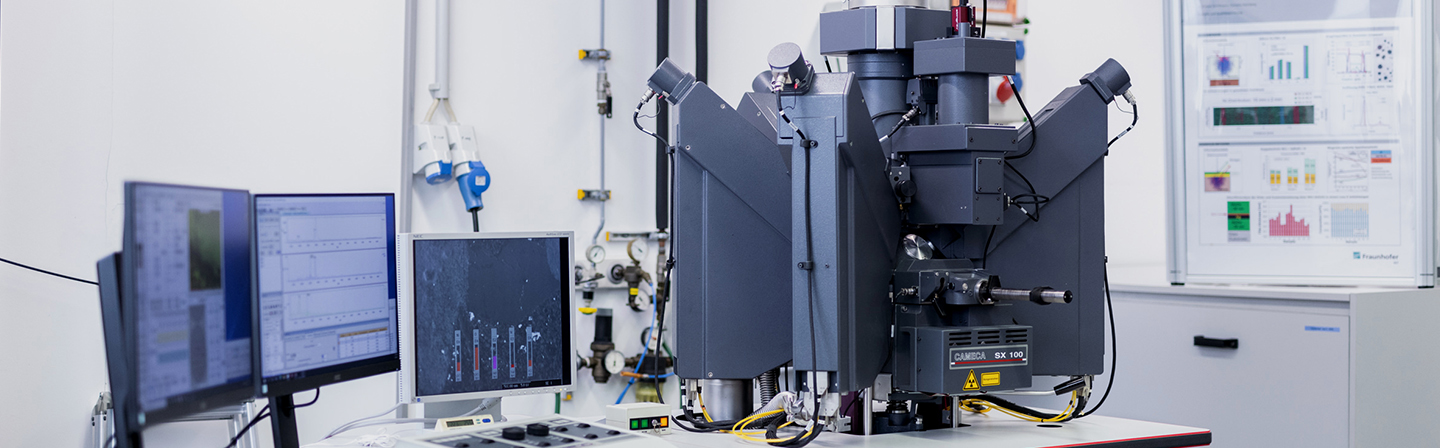

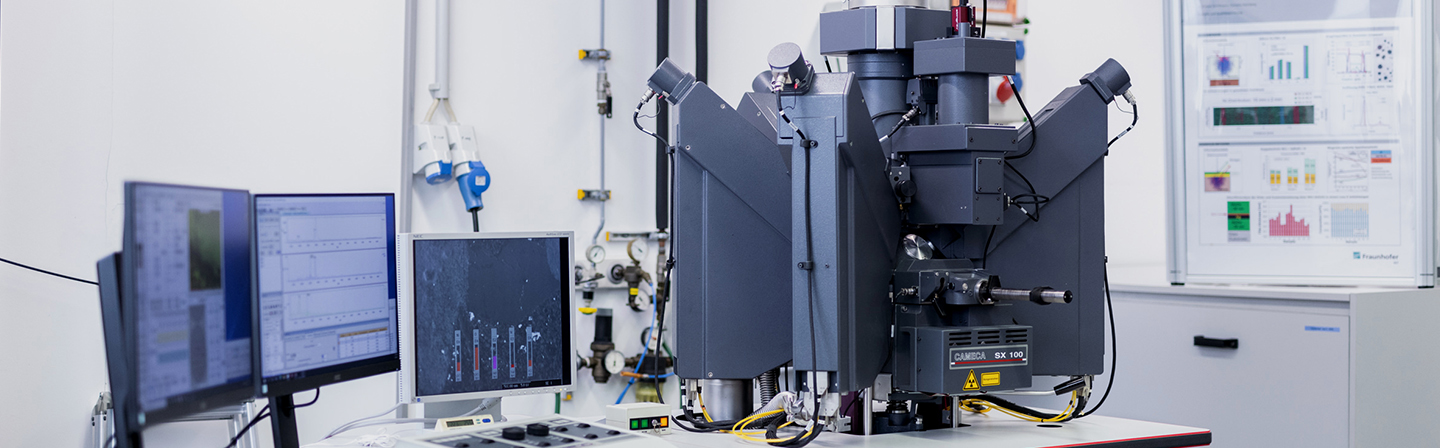

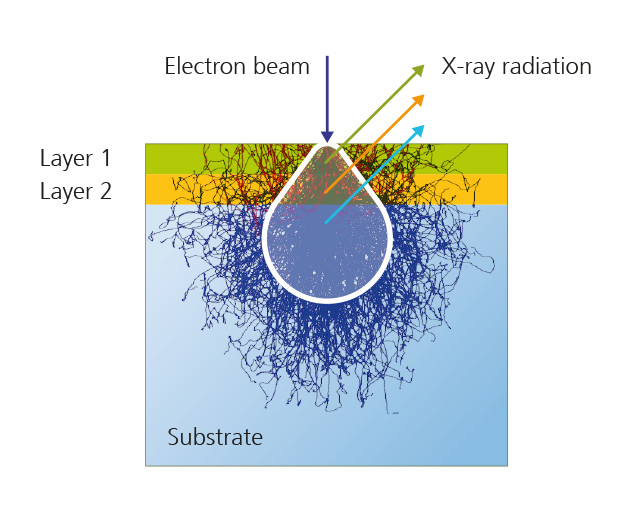

In EPMA analysis, a finely focused electron beam is directed to the sample surface in order to excite X-rays, which are then analyzed with the aid of several wavelength-dispersive crystal spectrometers. From the intensity of the characteristic X-ray radiation, the chemical composition can be determined with an absolute accuracy of 1-3 wt%. In the case of films thinner than 500-1000 nm, the thickness of single and multi-layer coatings can also be determined non-destructively under certain boundary conditions.

Bulk analysis of the chemical composition

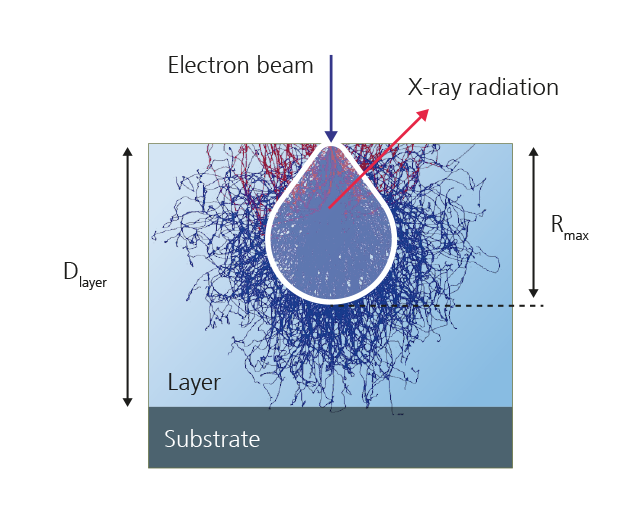

If the layers are relatively thick, i.e. >1µm, the chemical elemental composition can be measured independently of the substrate (see adjacent Figure above). The detection limit is thereby approx. 0.01 wt% and the relative accuracy 0.1 wt%. The spatial resolution lies at around 1µm due to the finely focused electron beam. Consequently, one and two-dimensional distribution of the chemical composition can be measured very well. For films of >10µm, this is also possible at the cross-section to measure depth profiles of chemical composition. Adjacent Figure (right) shows a cross-section through a piece of cast iron with graphitic precipitations. A linescan across one of the particles shows, in addition to the carbon in the particle, 0.03 wt% phosphorus and up to 0.13 wt% boron in a shell of the particle close to the surface (left). This demonstrates the high detection sensitivity and the very good spatial resolution of the method.

Thin-film analysis

For films which are thinner than 500-1000 nm, the film thickness can be measured simultaneously with the chemical composition. In this case, the electron beam will penetrate through the film into the substrate. The method is even possible with twofold or threefold film systems (see adjacent figure of a multilayer analysis). The prerequisite is that each chemical element only occurs in one of the layers or in the substrate, in order for the element radiation to be unambiguously assigned to one of the layers or the substrate.

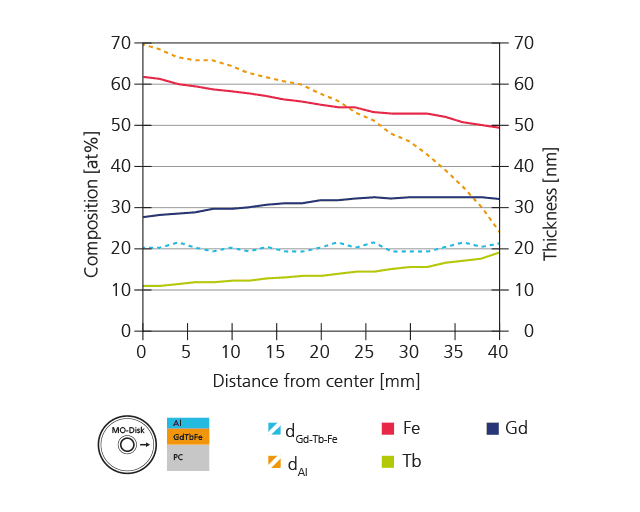

The adjacent graphic below shows an example of a magneto-optical storage disk made from polycarbonate with a Gd-Tb-Fe functional layer at the base, which is furnished with an Al protective layer. With the aid of EPMA thin-film analysis, the thickness of both films and the stoichiometry of the concealed magneto-optical layer can be simultaneously determined position-dependent point-by-point over the radius of the disk. A strong gradient in the film thickness of the GdTbFe film from 70 to 20 nm can be observed. At the same time, the (Gd+Tb)/Fe ratio varies significantly over the radius of the disk. The measurement duration for this analysis was approx. 45 min.

The thin-film analysis is so sensitive that, under favorable conditions, even monolayers of a material lying below some 10-100 nm of another material can be detected and measured. In a low-e glass coating, for example, it was possible to determine the thickness of a 0.3 nm-thick NiCr film below 30 nm of several metal oxide layers and to measure the stoichiometry from Ni to Cr.

More detailed explanations and further examples can be found in Vakuum in Forschung und Praxis, Vol. 31, No. 3 (June 2019), pp. 26-36.

This article is part of the annual report 2019.