Hygiene and cleaning through plasma and surface technology

Automated and sustainable solutions for clean surfaces

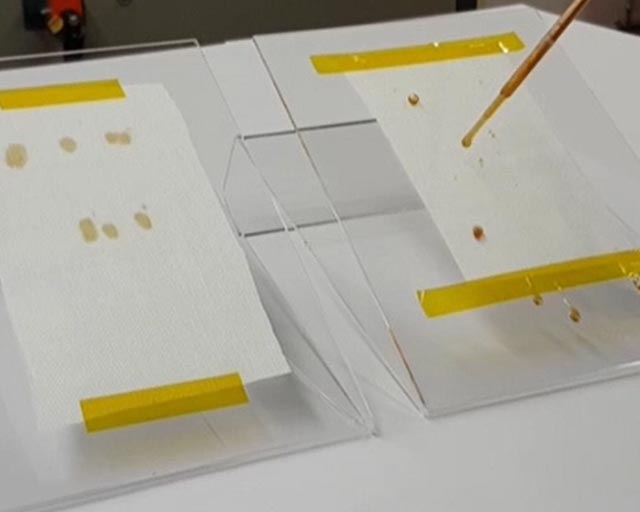

The COVID-19 pandemic has demonstrated it clearly: Whether in the medical sector or in mobility, clean and/or germ-free surfaces always play an important role. Two main areas of research are required here. Firstly, sustainable surfaces which preferably exhibit several easy-to-clean functions and, at the same time, retain a high level of long-term stability. Secondly, there is an increasing demand for mobile self-sufficient cleaning systems which can, for example, determine the contamination and the material, select the optimum cleaning procedure from this data, and then perform and document the cleaning in an automated manner.

Multifunctional surfaces and innovative self-sufficient cleaning systems

At the Fraunhofer IST we develop customer-specific solutions for multifunctional surfaces which exhibit, for example, antimicrobial, dirt-repellent or flame-retardant properties. We have comprehensive surface analytics at our disposal. This enables, amongst other things, coating composition and stability as well as wetting and microbiology to be verified. We are developing new cleaning systems and sensors at the IST. These include the in-situ production of e.g. ozonated water as well as the development of µ-plasma sources which can be integrated into robot-guided and mobile self-sufficient systems.

We offer you the optimal cleaning solution for your requirements

We develop functional surfaces and customized, integrable cleaning systems for you which are optimally adapted to your products. Benefit from our expertise along the entire process chain using modern plasma and electrochemical processes.