M2ARS – Modifications of membranes for wastewater treatment of heavy metals

Fraunhofer IST has developed an atmospheric pressure plasma process to specifically functionalize filter membranes in order to improve the purification of wastewater from heavy metals.

The Challenge

According to the Food and Agriculture Organization (FAO), 1.8 million people in the United States alone will suffer from absolute water shortages in 2025. The treatment of water of suitable quality is therefore of enormous importance. The aim of the "M2ARS" project was to develop a surface-functionalised filter membrane made of low-cost polypropylene (PP) which binds harmful metal ions contained in water to the surface of its pores in a highly selective manner. A further advantage in addition to this selectivity is that the filtering is based on the principle of adsorption, so that the membrane does not have to be nanoporous. This eliminates the need for high pressures. At the same time, the risk of blockage of the membrane is significantly reduced. The atmospheric pressure plasma process for functionalizing the membrane allows plasmas to be ignited even in the smallest cavities down to 10 µm.

The Surface Treatment

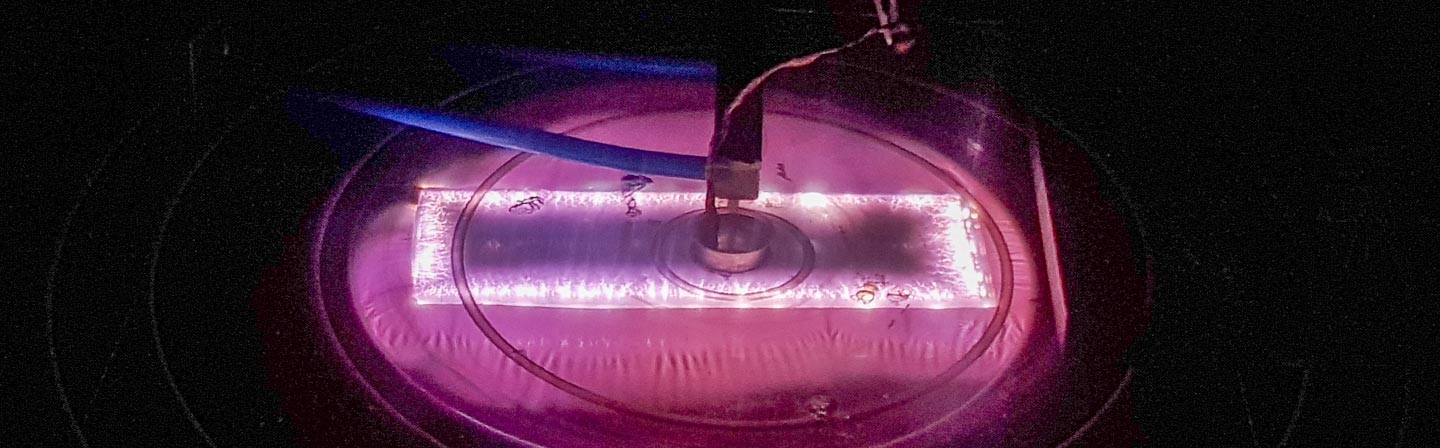

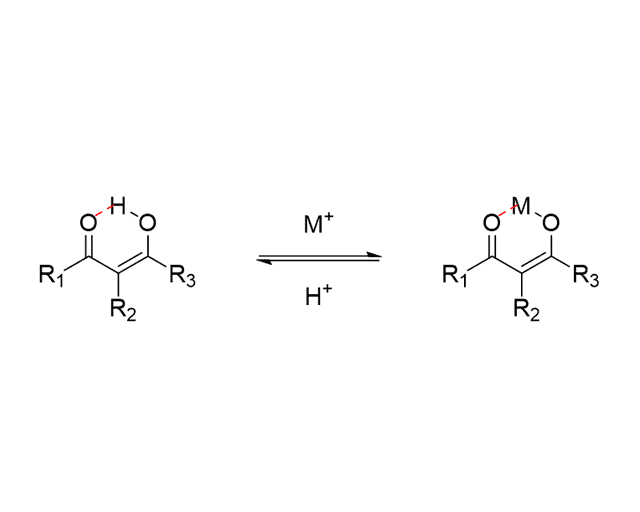

Metal ions can be bound in the form of so-called chelate complexes. The metal ions form the central atom, which is bound by a multidentate ligand, i.e. a molecule which has at least two free electron pairs. In this coordinative bond, the binding electrons are provided solely by the ligand. Using atmospheric pressure plasma functionalization, the Fraunhofer IST was able to generate so-called β diketones on the PP surface, which bind the metal ions as ligands in the form of chelate complexes (see figure on the opposite). To this end, a suitable test rig for the generation of β diketones was first set up and tested using a plasma process based on the principle of dielectric barrier discharge (DBD) at atmospheric pressure. By using porous electrode materials, the gas flow could be directed through the membrane (see figure above).

The Results

Within the project period, a basic functional proof on flat substrates could be provided: the β diketones on the PP surface as well as the binding of metal ions could be successfully proven by FTIR-ATR and XPS spectroscopy. On the β diketone-functionalized PP surface, for example, corresponding chelate complexes with iron(III) ions were formed after maturation in an aqueous iron(III) solution.

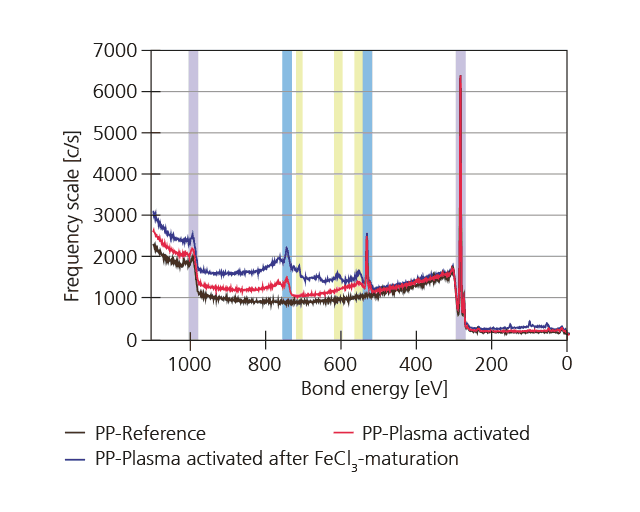

The opposite figure shows the overview XPS spectra of an untreated PP layer, a plasma-activated PP layer and a plasma-activated PP layer after maturation in an aqueous iron(III) solution. The desired oxygen-containing functionalization was achieved by plasma activation. Iron was clearly detected on the removed sample, whereas hardly any chlorine was detected. Thus, it could be shown that only iron ions were bound on the surface. In another test series, the plasma-functionalized PP layer was matured in a copper(II) solution. Here, too, the adsorption of copper was successfully demonstrated. The process was also transferred to the 5 mm thick filter material. The penetration depth of the treatment was examined by staining with methylene blue. So far, no complete penetration of the material has been achieved.

The Outlook

In the future, optimizing plasma-activation and adapting membrane material (e. g. thickness, membrane material) should result in full material activation. Additional plans include testing membrane material with regard to filtration performance of metals. One important focus will thereby be the membrane regeneration and the relating recovery of filtered metals. On the basis of the evaluated plasma process, which can be easily transferred into an industrial roll-to-roll process, further interesting research fields can be opened up, such as the isolation of fine chemicals from industrial waste materials. In paper production, for example, more than 500 million tons of black liquor are produced annually worldwide, which, in addition to lignin as the main product, contains other valuable chemicals such as vanillin, pesticides and pigment carbon black.

This article is part of the annual report 2019.