Cold plasma spraying for three-dimensional molded interconnect devices

In many branches of industry, three-dimensional molded interconnect devices, MID for short, are increasingly gaining in importance. The integration of mechanical, electrical and optical functions into a component enables the miniaturization and rationalization of assembly units. Injection-molded parts are predominantly used as the basis for MID components. Under the catchword “additive mechatronization”, the development of new processes, for which the additive generation of mechanical structures is combined with electrical functionalization, is currently being brought to the fore.

Advantages over conventional metallization processes

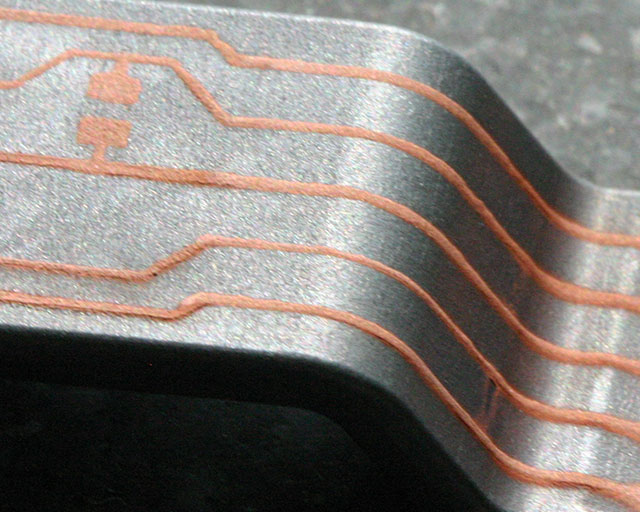

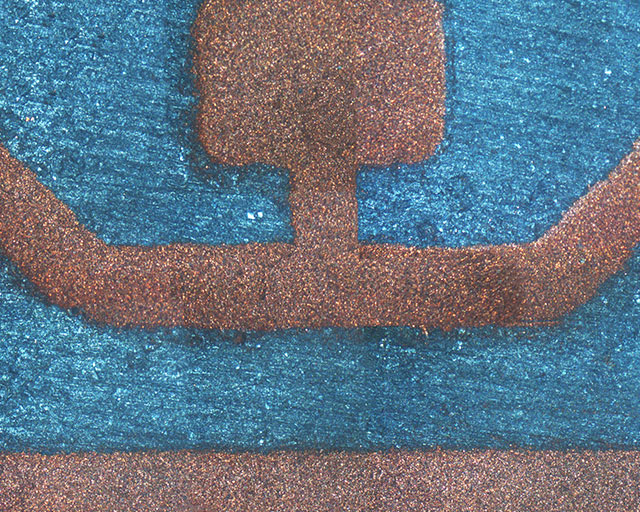

For the selective metallization of polymer surfaces, procedures are primarily applied in which galvanic or wet-chemical process steps are necessary. Through prior laser structuring (as in so-called laser direct structuring), or through drying and sintering processes subsequent to the metallization, the process chain for the established procedures is comparatively extensive. Cold plasma spraying, developed at the Fraunhofer IST Application Center for Plasma and Photonics, enables polymer components to be selectively metallized without wet chemistry and without pre- or post-treatment steps. The adjacent figures top and middle show sections of such an MID component.

The technology

The main feature of cold plasma spraying is the utilization of a low-temperature plasma jet, generated from e.g. air or nitrogen. Particle-bearing aerosols or suspensions of ultra-fine character are fed into the process gas. In comparison to the powder material used in established processes such as thermal plasma spraying or cold gas spraying, the spray additive in cold plasma spraying exhibits a smaller particle size/mass or is morphologically so designed that the specific surface area is large.The coating material can therefore be efficiently melted in a low-temperature plasma jet. The heat transfer to a substrate is locally limited at the point of impact of the spray particles and occurs within a short period of time, i.e. until the molten spray particles solidify into so-called splats. This makes it possible to apply metal coatings to thermally and mechanically sensitive underlays such as polymer and elastomer components, natural materials such as wood and paper, or thin films, without causing damage.

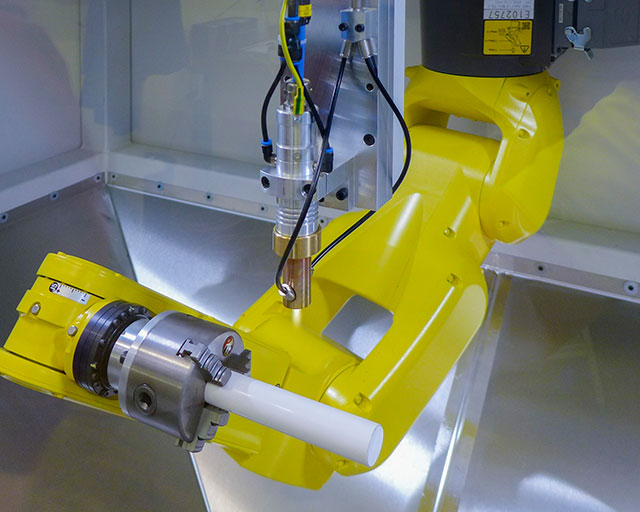

The coating is produced without the use of binders and without wet-chemical pre-procedures. Per passage, layer thicknesses of 5 - 20 μm at a coating speed of approx. 100 mm/s can be realized. The objects are additionally refined under ambient pressure, enabling the process to be integrated into more complex inline-capable procedures. Due to the high degree of automation and the kinematic flexibility of a robot-aided coating facility, it is also possible to produce more sophisticated 3D molded interconnect devices (see the adjacent figures top and bottom). This enables the production of a wide range of functional layers for plastics. For example, plastics can be metallized in order to stabilize the substrate or can be equipped with a high electrical or thermal conductivity or antibacterial effect.

Further application examples include:

- Anti-static coatings

- Coatings for shielding against electromagnetic interference radiation

- Thermally conductive layers

- Friction coefficient reduction

- Antimicrobial functional layers

- Adhesion-promoting layers

- Anti-adhesive layers

- Barrier layers

- Optical layers

- High-current-viable layers

Advantages of MID components created through cold plasma spraying

An important advantage in the application of cold plasma spraying for the production of MID components is that simple multi-layer systems can be realized. The possible layer materials encompass the most diverse metals from copper, aluminum and tin through to refractory materials such as titanium. Furthermore, plastic layers can also be deposited in which thermoplastics such as Teflon or polyethylene serve as the starting material. The wide range of layer materials also enables the combination of widely varying materials: As an example, conductive layers can be equipped with protective layers which prevent degradation under mechanically or chemically onerous environmental conditions. Bond-promoting primers can also improve layer adhesion. The targeted combination of individual layers also enables the reduction of local layer tensions, e.g. in transition areas between materials with different thermal expansion behavior.

A further advantage of cold plasma spraying is obtained through the utilization of bimodal composite particles: Carrier particles can be coated or loaded with a different material. The use of such composite particles enables the reduction of imperfections or oxide phases and therefore improves the mechanical and electrical properties of the layer. Through the utilization of mixed powders, in which differing metals are present as particles, different material properties can be combined with one another.

The general advantage of cold plasma spraying, in addition to the low-temperature process control, is the renunciation of wet chemistry and environmentally harmful solvents or binders. Furthermore, neither pre-treatment nor post-treatment of the layer products is necessary.

Outlook

At the Fraunhofer IST, cold plasma spraying is continuously being further developed in terms of both equipment and procedures. Currently, the focus is being directed on the integration of inline-capable diagnostic systems such as spray-jet and object-temperature measurement, on quality assuring analysis methods such as spatially resolved eddy current measurement, on process optimization in selective metallization with specific masking techniques, and on a combination of 3D printing processes with cold plasma spraying.