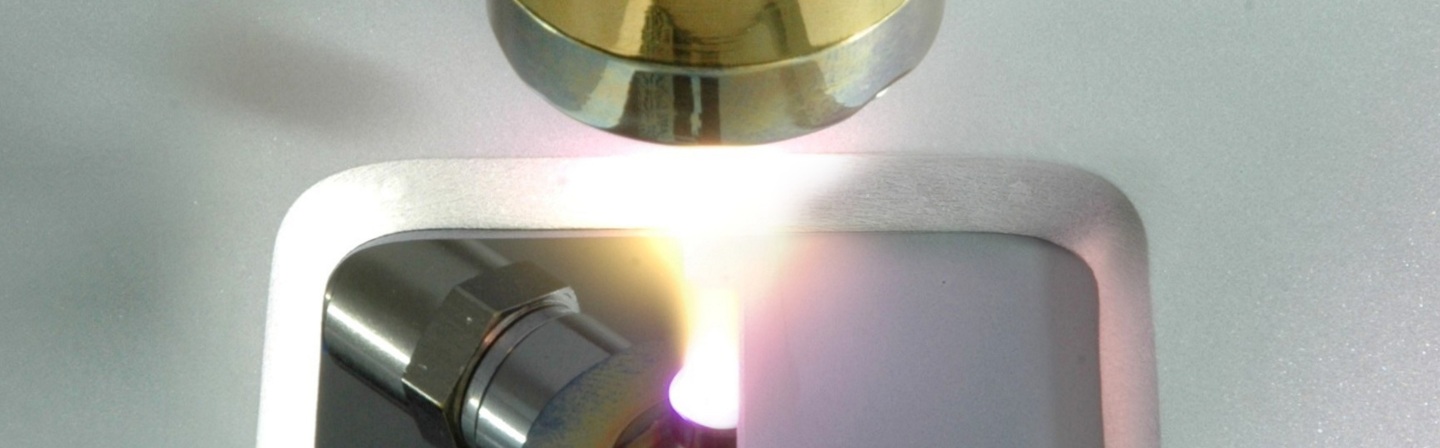

Cold plasma spraying

Innovative technology with low energy input

Cold plasma spraying is a thermo-kinetic coating technology which differs from conventional technologies such as thermal plasma spraying, which has been commercially available for decades. The main feature of the technology is a low-temperature plasma jet generated from air or nitrogen, into which ultra-fine metal particles are injected. This type of coating material is melted very efficiently in the plasma jet. In this way, not only the plasma input power and the energy consumption but also the thermal load on objects can be minimized. With this process, it is possible to create both narrow conductive path structures and coatings which cover the entire surface. Thanks to a special powder-conveying technique, aluminum, constantan, stainless steel, and titanium as well as metal combinations in the form of homogeneous or graded layer systems can be created in addition to the classic metal types used in electrical engineering.

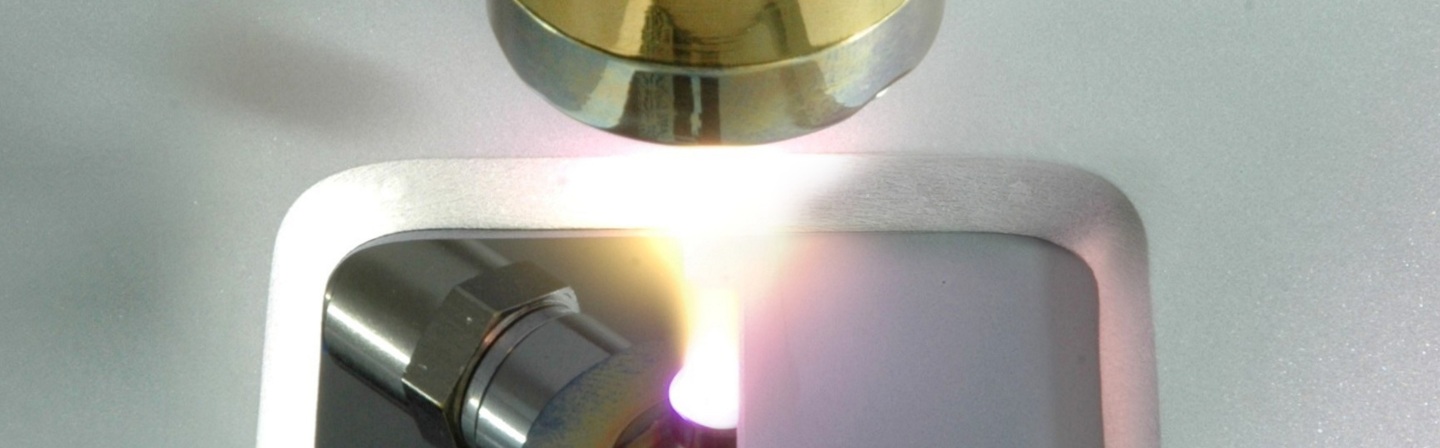

Coating of thermosensitive materials

Thermosensitive materials such as polymer films, textiles, wood, etc. can be coated, e.g. metallically, using cold plasma spraying. In the case of textile fabrics, each individual fiber is thereby coated without damage being caused to it. The reactive species present in the plasma can also effect specific chemical/physical changes in the starting materials. For example, the stoichiometry of a photocatalyst can be altered with the aid of cold plasma spraying, which has a positive effect on the band gap and, consequently, on the catalytic effect.