Smart screw connection – Wireless and energy-autonomous monitoring solution

Challenge

A drop in the pre-tensioning force can have serious consequences for load-bearing elements that are subjected to heavy mechanical or thermal loads. Safe operation can then no longer be guaranteed. For this reason, a smart screw connection should be developed as a completely integrated IoT device for energy-autonomous, wireless, tamper-proof monitoring.

Solution

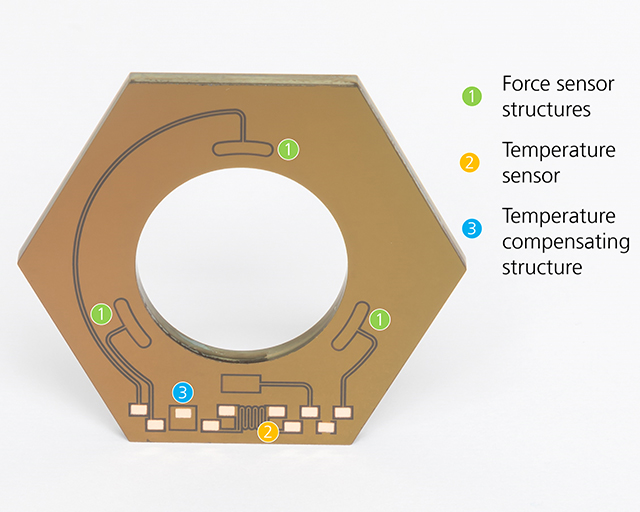

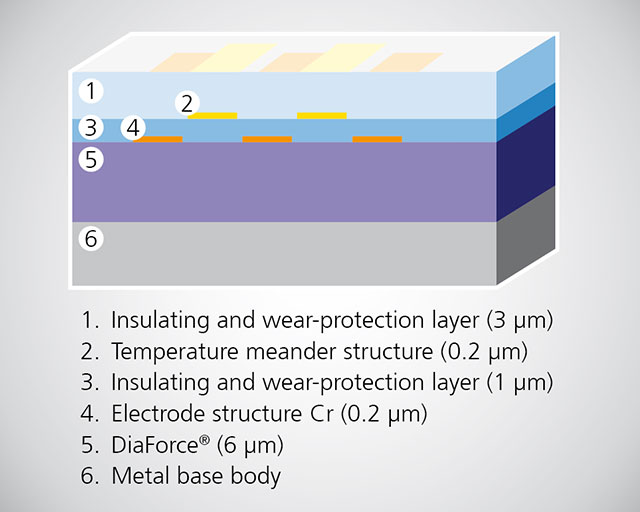

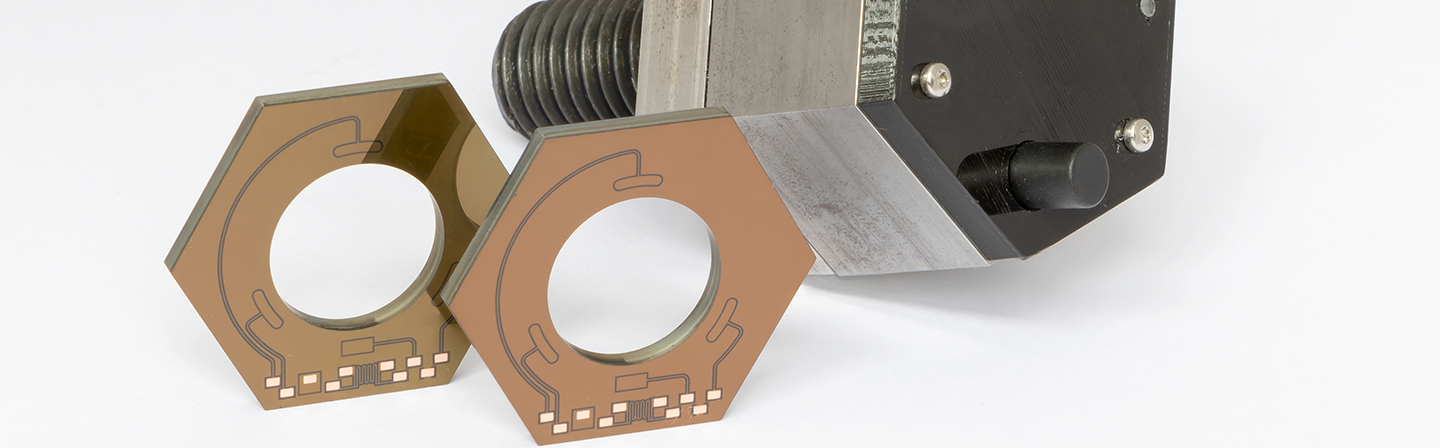

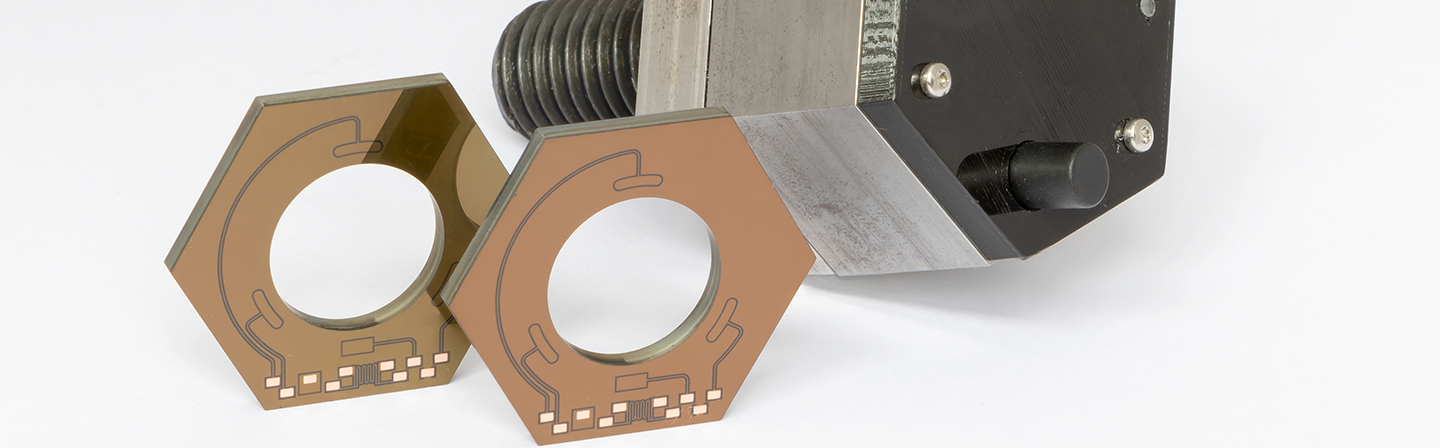

At the Fraunhofer IST, a thin-film system for force and temperature measurement was deposited on the surface of washers. This system was integrated into screw connections and combined with wireless transmission technology and energy harvesting technologies. The thin-film system consists of the piezoresistive DiaForce® layer and the electrically insulating and wear-resistant SiCON® layer, a hydrocarbon layer modified with silicon and oxygen. These are deposited by means of the PACVD process (plasma-enhanced chemical vapor deposition). In between are sensor structures made from chromium and manufactured by means of microstructuring. The total thickness of the system is approx. 10 µm.

Added value

With the “intelligent screw connection”, wireless, energy-autonomous monitoring of the preload force is possible with the help of a retrofittable sensor system for DIN screws during assembly and operation. Deviations can be detected immediately via remote maintenance and downtime or maintenance times can be avoided – a complete control of critical screw connections.

Funding reference

This solution is being developed within the framework of the Fraunhofer research center IoT-COMMs in collaboration with the Fraunhofer institutes IIS, IST, LBF and AISEC. FIoTCOMMs is part of the Fraunhofer-Gesellschaft's cluster initiative CCIT (Cluster of Excellence Cognitive Internet Technologies).