Aluminum coatings – limits of electroplating

Challenge

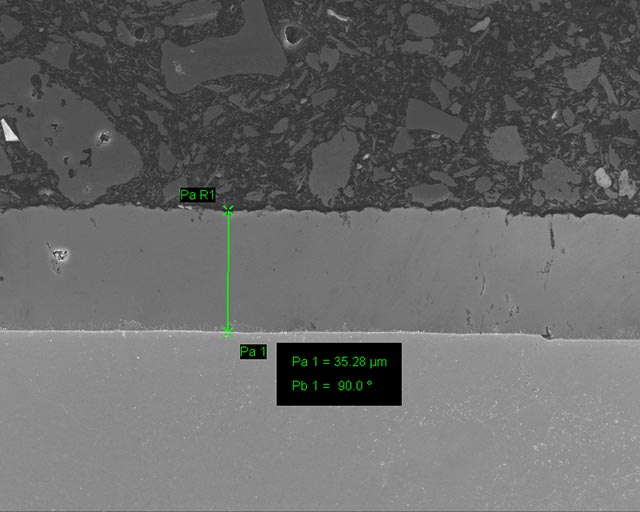

Within the scope of this project, the electrodeposition of a number of metals from ionic liquids was investigated. Metals such as titanium, tantalum or aluminum have good corrosion protection and are catalytically active, but cannot be electrodeposited from aqueous systems. The task of the IST was the up-scaling of aluminum deposition with the aim of technical implementation.

Solution

For the up-scaling of aluminum deposition, it was important to develop a system outside of a protective glove box. The processes with ionic liquids are extremely sensitive to moisture. Consequently, an open apparatus was constructed, which protected against the entry of moisture by means of a flow of dry inert gas. Special zeolites in the electrolyte were used to additionally trap incoming water molecules. The Fraunhofer IST was thereby a pioneer in the transfer of the electroplating process from the glove box to a semi-technical apparatus.

Added value

The result of the project was a greatly simplified process with a new class of (less expensive) ionic liquids for the deposition of aluminum. Further projects in the field of Li batteries as well as cadmium substitution with electroplated Al layers are planned. A DLR-funded project is currently being conducted which addresses metal extraction from lunar regolith based on ionic liquids (ELMORE).