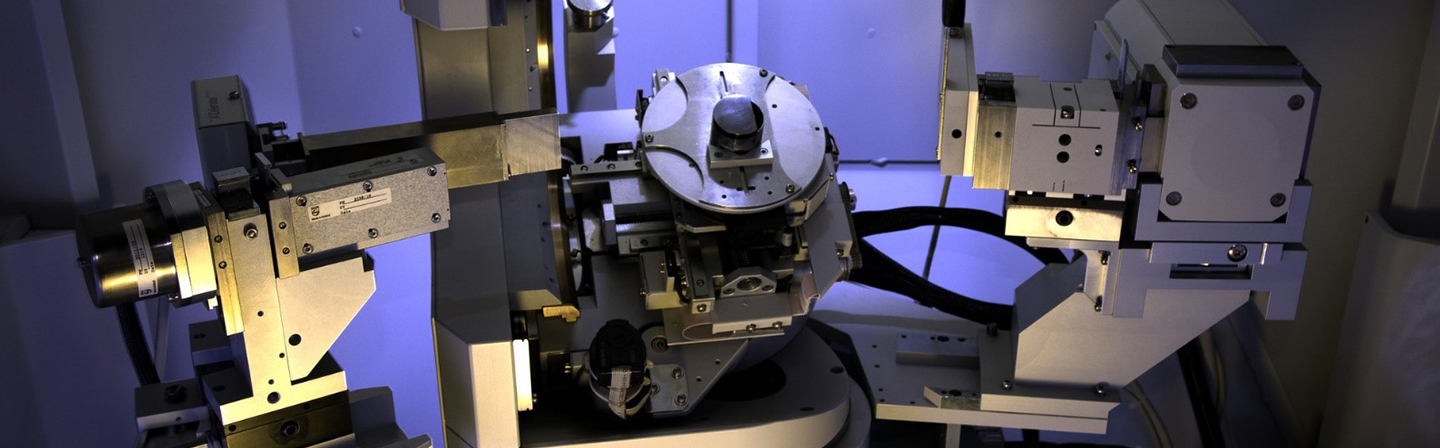

Structural investigation of crystalline materials: X-ray diffraction (XRD)

X-ray diffraction (XRD)

X-ray diffraction (XRD) is a versatile technique for studying the structure of crystalline materials, i.e. crystal structure analysis. Applications include the determination of:

- Crystallographic phases

- Grain sizes

- Textures

- Residual stresses (stress)

- Nanometer layer thicknesses, density, roughness by X-ray reflectometry (XRR)

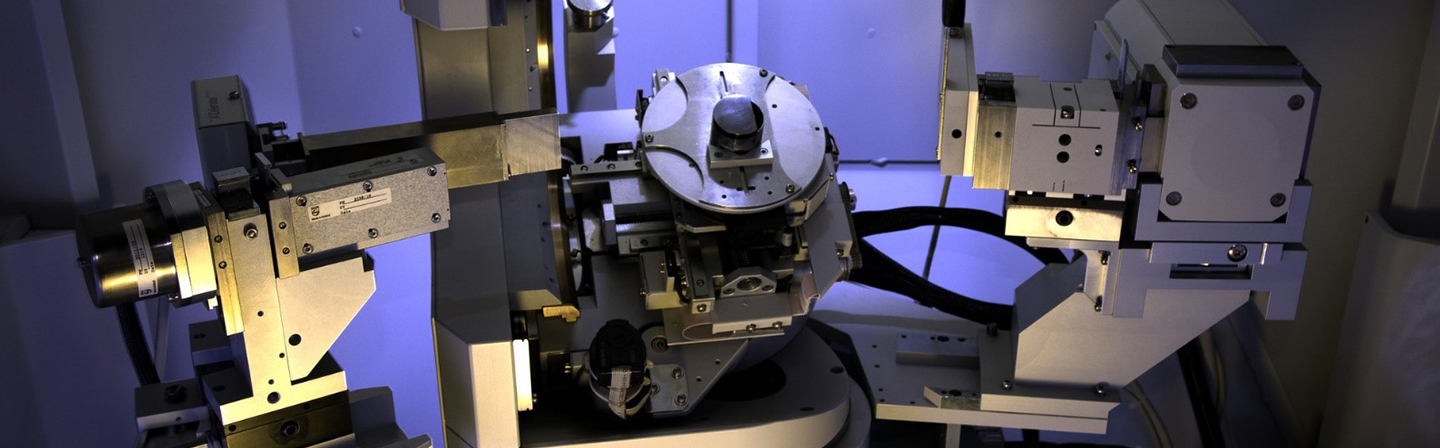

The examination can be carried out on flat as well as on curved component surfaces. One specialist field of the Fraunhofer IST is the characterization of thin films (micrometers to nanometers)

X-ray diffraction often provides complementary information to chemical characterization and these are often used in combination. A 1-dimensional position-sensitive semiconductor detector, with which standard measurements can be accelerated by a factor of 10-50, is an advantage at the IST.

Grazing incidence measurements allow the investigation of the thinnest layers down to the nanometer range, and the entire coating-technology expertise of the Fraunhofer IST is available to provide a background for the evaluation.

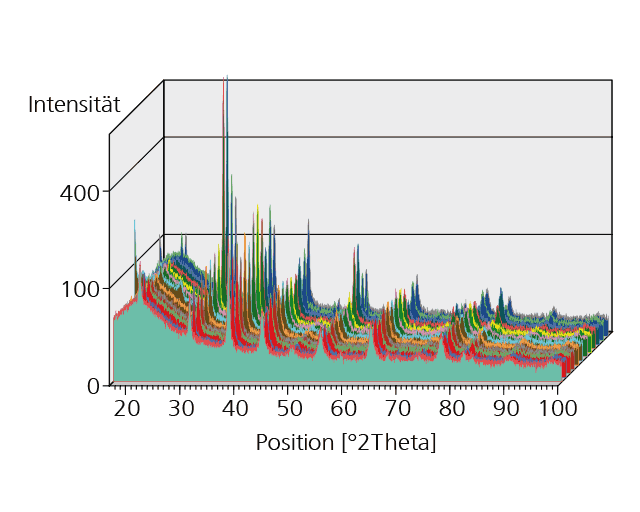

XRD phase analysis

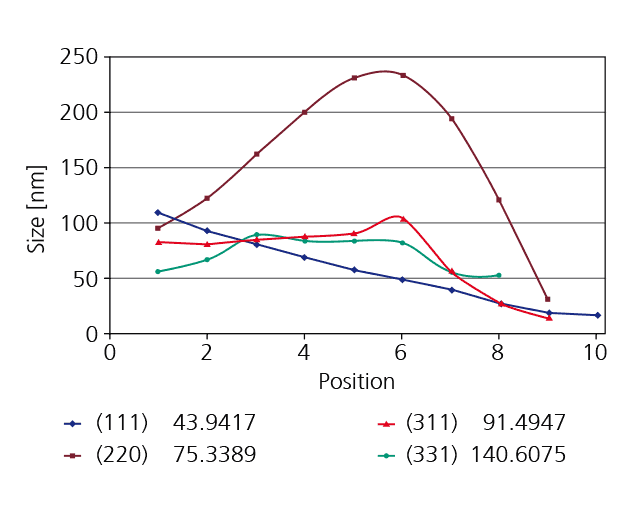

XRD grain-size determination

Spatially resolved determination of grain sizes in a polycrystalline diamond film. Measurements were made with a spatial resolution of 1 mm over a distance of 10 mm, and grain sizes were determined separately for differently oriented crystals in which the (111), (220), (311) or (331) network planes lie parallel to the sample surface.

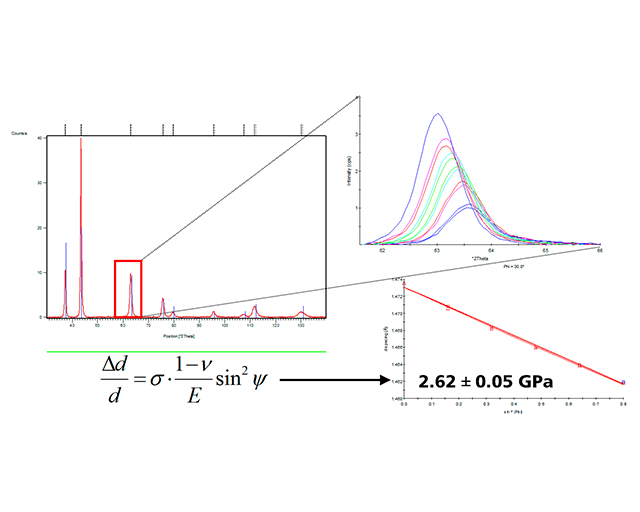

XRD residual stress analysis

In residual stress analysis, the sample is generally tilted transversely to the beam path, whereby differently stretched or compressed mesh planes are recorded. From the resulting shift of the diffraction reflections, the layer stress can be determined. Example: Residual stress of 2.6 GPa measured on a PVD CrN layer (thickness approx. 20 µm). By means of a special method, residual stresses can also be determined in grazing incidence, which means that even very thin surface layers can be characterized.