Process chains and systems for components and tools

The minimization or optimization of friction and wear is a fundamental challenge for many tools and components. The tribological properties have a significant influence on the service life and sustainability of products and the associated production systems.

Process chains and systems analysis for tools and components

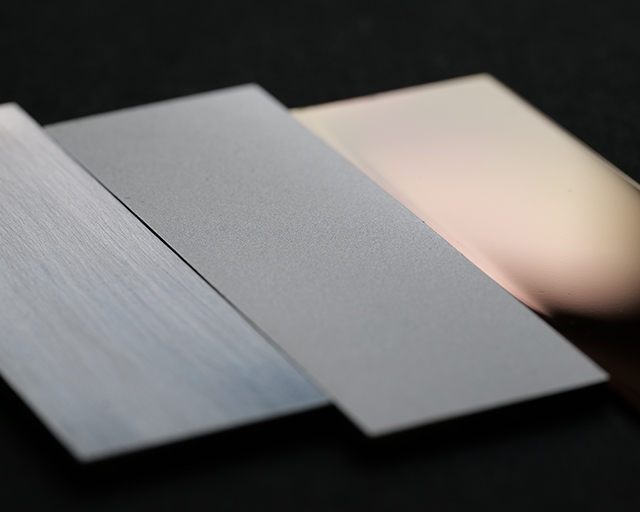

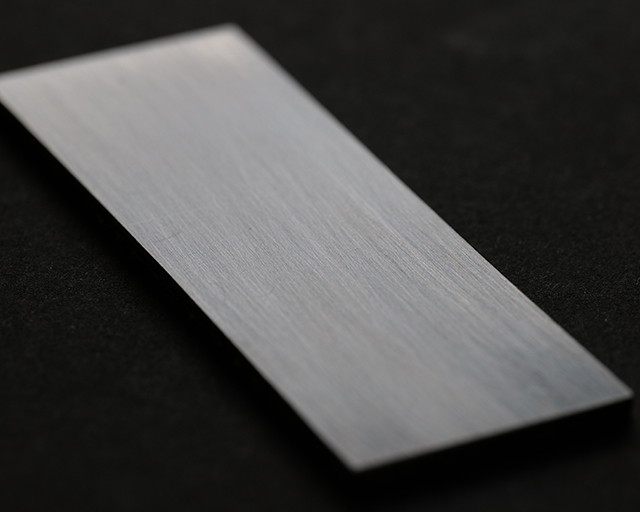

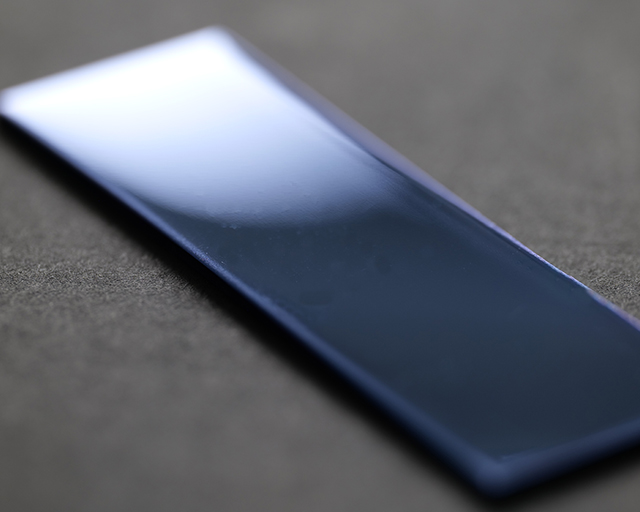

The surface properties of tools and components are decisive for their tribological effect. An increase in service life and sustainability can be achieved through consideration of the process chain and the system properties. Important influencing variables for the function and for an application-optimized design of surface treatments and coatings include, in particular, the load spectrum in the application, as well as the material, manufacturing process, surface topography, pre-treatment and post-treatment, cleaning process, etc.

Load-optimized surfaces for customer-specific applications

With our expertise in the areas of coating production, quality assurance and coating application as well as wear and application assessment for tools and components, a broad spectrum of coating classes, edge layer and surface modifications can be realized. Surface design can be supported by laboratory experiments and specific model tests. By taking into account the entire tribological system, the application profile and the complete process chain when designing the coating, we are able to optimize and adjust surfaces in customer-specific applications with regard to the load and performance needs.