Reduction of particle pollution in coating processes

In optical coatings, particles may manifest as layer defects, compromising the image quality, performance compatibility and longevity of the optics, particularly in the short-wave spectral range or in laser applications. The reduction of layer defects in optical coatings is therefore one of the most important goals of modern coating technologies. Within the framework of the “EVAPORE” project, mechanisms which can lead to the formation of particles were investigated. In order to better comprehend the behavior of dust particles in coating processes, the Fraunhofer IST had developed a program which is capable of simulating the movement and charging of dust particles, resulting in the simulation software PALADIN – Plasma Lattice Dust Integrator.

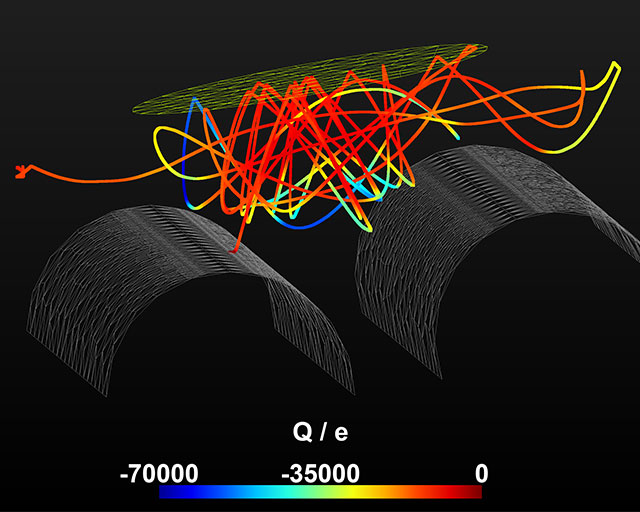

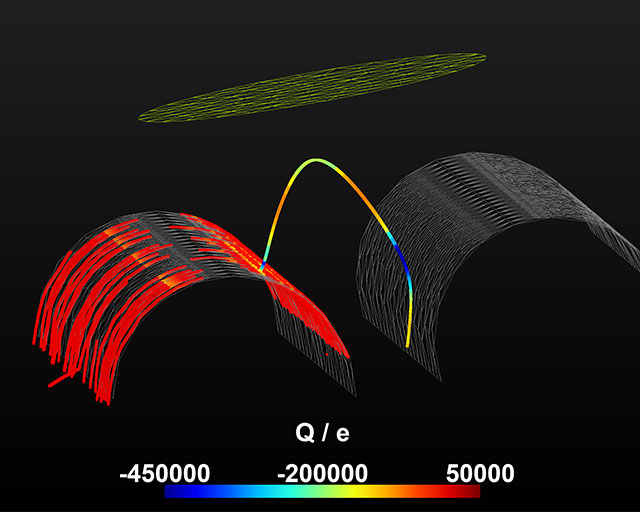

PALADIN – Plasma Lattice Dust Integrator

The PALADIN software is able to simulate the movement of particles in any chosen three-dimensional geometry. Grid-arranged results from a previously performed plasma simulation, also developed at the Fraunhofer IST, are thereby used in order to calculate the forces and currents acting on the particles based on a physical model. Furthermore, collisions of the particles as well as their adhesion in dependence of the geometry are calculated and recorded.

By simulating a large number of particles, statistics can be generated, e. g. concerning the acting forces or the size distribution of the particles adhering to the substrate. In addition, the path of the particles can, in principle, be reconstructed back to their origin; this makes it possible to determine where most of the particles impairing a surface actually come from.

Investigations for an avoidance strategy

Within the scope of the project, a multitude of influencing factors were examined with regard to their impact on particle pollution during the coating process. The aim was the development of strategies for the avoidance of particles. For this purpose, various process parameters, such as process pressure, gas flow, discharge power and pulse frequency, as well as the influence of the target material and the manufacturing method, were tested experimentally. The alteration of the target-substrate distance and a variation of the magnetic field during magnetron sputtering also formed a part of the investigations.

The results

The correlation between the frequency of occurrence of so-called “arcs”, i. e. arc discharges, and the particle pollution in the coating process has proven to relatively clear. Such arcs usually occur in areas in which insulating layers form and a high electric field strength is present. Furthermore, the results showed that silicon-based particles – the standard material for low-refractive layers – cause a higher particle pollution than typical high-refractive materials such as tantalum pentoxide. The most plausible reason for this is the lower mass of the Si atoms compared to other materials, such as tantalum (Ta) or niobium (Nb). FIB-REM analyses on selected samples support these results. It was also observed that the magnetic field of the cathodes appears to have an influence on the formation of particles.

Outlook

In the future, further investigations should expand the database, thereby providing better possibilities for statistical statements concerning the various influencing factors in the coating process with regard to their relevance for particle pollution as well as enabling a deeper understanding of particle formation. The aim is a continuous improvement of the coating process and thereby a minimization of the defect density.

The project

“EVAPORE – Entstehungsdetektion und Vermeidungsstrategien von Mikropartikeln in Plasmabeschichtungsprozessen für die optische Industrie” (EVAPORE – Origin-Detection and Avoidance Strategies for Microparticles in Plasma Coating Processes for the Optical Industry) is an IGF project (funding number 18590 N) of the Forschungsvereinigung Feinmechanik, Optik und Medizintechnik e. V. (Research association for precision mechanics, optics and medical technology).

This article is part of the annual report 2019.