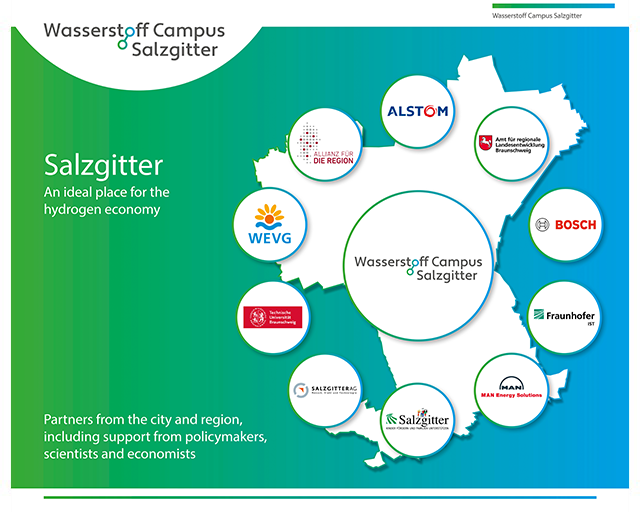

At the Wasserstoff Campus Salzgitter, a broad alliance from industry – Salzgitter AG, MAN Energy Solutions, Robert Bosch Elektronik, Alstom Transport Deutschland and WEVG Salzgitter – in collaboration with local government partners, including the office for regional development and the city of Salzgitter, as well as the Allianz für die Region and the Fraunhofer Institute for Surface Engineering and Thin Films IST, is conducting application-oriented research of business models along the entire hydrogen value chain, with a focus on decarbonization of the industrial sector. In addition to working on projects, the goal of the campus is to translate research results into consulting, education and training services for higher education and vocational training. By setting up a hydrogen demonstration infrastructure, the campus also allows for the testing and demonstration of innovative technologies in practice.

Transformation of the Salzgitter industrial site with green hydrogen technologies

Technical work at the Wasserstoff Campus Salzgitter

At the beginning of 2021, four projects were started at the Wasserstoff Campus Salzgitter. These involve the decarbonization of factory systems, a concept for supplying the Salzgitter region with green hydrogen, the development of steel tanks for transporting and storing the energy source, and the establishment of an overarching innovation network. The State of Lower Saxony and the City of Salzgitter are supporting the projects with around five million euros from the structural assistance program.

The primary goal of the campus is to develop innovative solutions for Salzgitter as a CO2-neutral industrial center and to consolidate the campus itself by setting up a demonstration infrastructure and developing consulting, training, and continuing education offerings.

Testing the decarbonization of the industrial sector on real hydrogen infrastructure

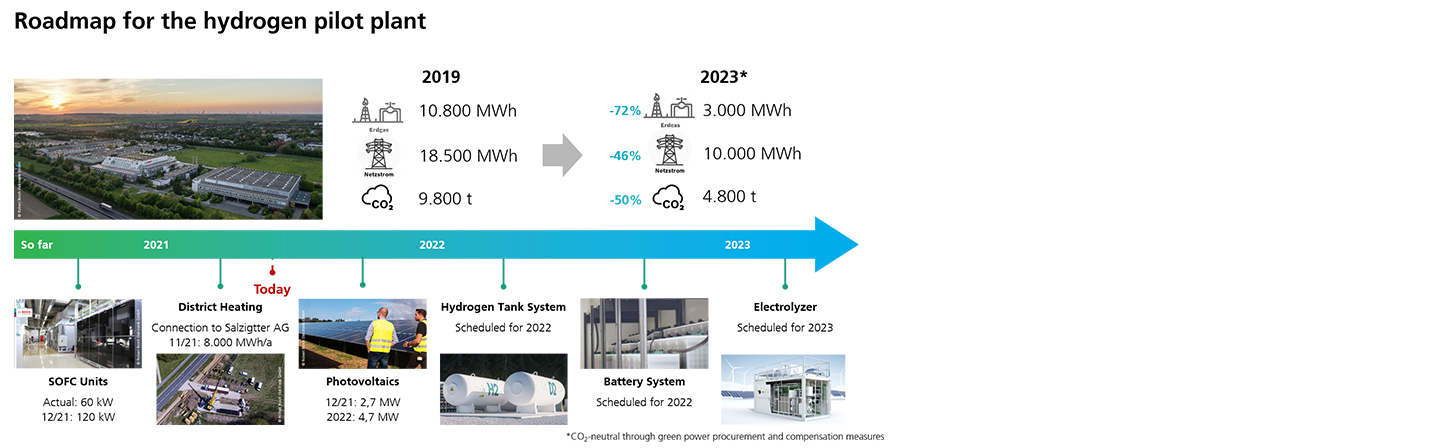

In the ”Factory Transformation” project, a blueprint is being developed for the decarbonization of factory systems, from planning to plant operation. With the aid of a digital factory image produced by Fraunhofer IST, design and operating scenarios for hydrogen technologies are being evaluated in terms of technology, economy and the environment, thus laying the groundwork for the assessment of investment in new hydrogen infrastructure. In the course of the investigations, an additional five million euros have been invested in new infrastructure at the pilot factory of Robert Bosch Elektronik GmbH, in particular in photovoltaic systems, district heating and fuel cell systems. This has particularly increased the potential for the CO2-neutral provision of heat and power. In the coming years, further investments will be made to integrate additional elements such as battery storage or electrolysis and refueling systems for hydrogen in order to reduce CO2 emissions from the pilot plant by 50 percent, or 5,000 metric tons of CO2.

Prerequisites for the transition to low-carbon industry

Based on the factory model developed, and using the potential CO2 savings demonstrated from the Bosch Salzgitter pilot factory, it is possible to implement the design of further factory systems in different application areas, so that significant savings effects can be generated by means of scaling across the industrial sector. Identifying sustainable business models for individual hydrogen technologies in the factory system under current boundary conditions enables the early establishment of a market, thus creating good conditions for system and component development in Germany. The project demonstrates how decarbonization of the industrial sector can succeed with the use of renewable energy and energy storage systems, in this specific case hydrogen and batteries, through generic approaches from research combined with practical expertise from industry.

Outlook

In 2022, further projects are set to be located at the Wasserstoff Campus Salzgitter, including the manufacture and recycling of fuel cells, the production of electrolyzers, energy flexibilization and the design of refueling systems. Another important cornerstone is the expansion of activities to include education, training and continuing education offerings. In this context, a basic training course on hydrogen economy and hydrogen technologies will be offered at the campus at the beginning of the second quarter in collaboration with the Fraunhofer Academy and other campus partners.

The project

The ”Factory Transformation” project is funded by the State of Lower Saxony and the City of Salzgitter.

This article is part of the Annual Report 2021.