X-ray photoelectron spectroscopy: XPS / ESCA

How XPS / ESCA works

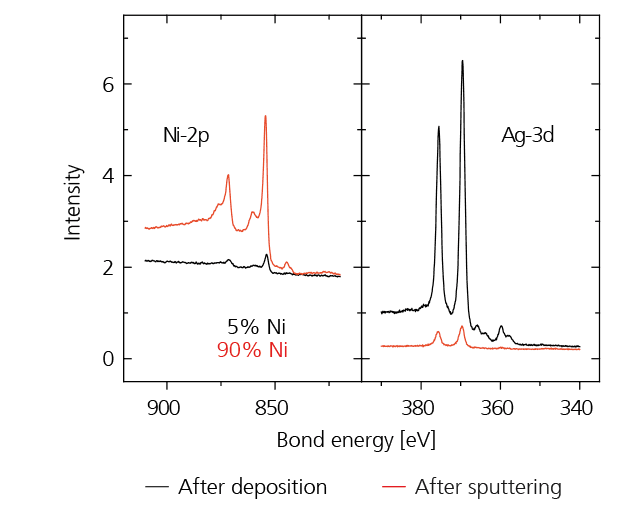

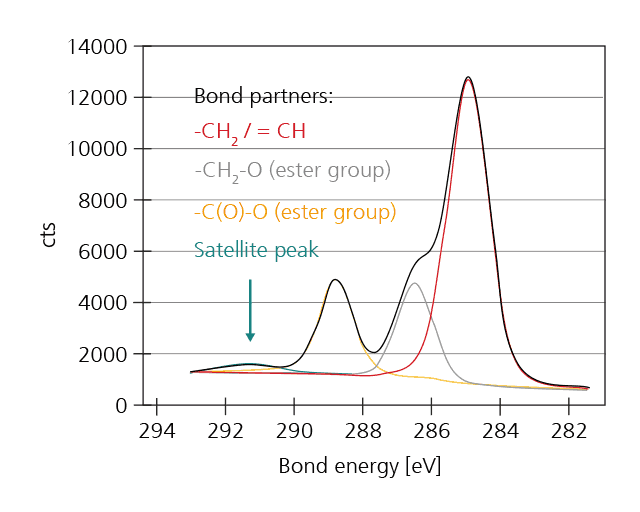

The X-ray photoelectron spectroscopy or also photoelectron spectroscopy (XPS, often also electron spectroscopy for chemical analysis, ESCA) is a chemical analysis method that is characterized by secular surface sensitivity with a signal depth of around only 5 nm. X-ray bombardment produces photoelectrons whose energy allows conclusions to be drawn concerning the material composition on the basis of element-specific energy levels (all elements except H and He). Since the chemical environment of an atom influences the energy levels of the electrons, XPS also offers the possibility of making statements regarding bonding states, oxidation states or the proportion of different bonding partners.

Applications of X-ray photoelectron spectroscopy (XPS / ESCA)

XPS analysis provides information on chemical composition and bonding states near the surface and also allows depth profiles as a result of the integrated ion gun. XPS analysis is used, for example, in the following areas:

- Analysis of surface impurities, e.g. in the form of slight discoloration

- Inspection of cleaning processes

- Chemical analysis of ultrathin layers, e.g. passivation layers

- Analysis of surface treatments, e.g. surface analysis for plasma treatments