Fields of application for atomic layer deposition

Homogeneous and nanometer-precise coatings are playing an increasingly important role in numerous fields of application, such as in the manufacture of fuel cells, lithium-ion batteries and corrosion-resistant coatings for automotive parts. For this reason, the Fraunhofer IST has long been successfully developing ALD processes with which such coatings can be produced. In a joint project with the Institute for Particle Technology at the TU Braunschweig, the Fraunhofer IST has, amongst other things, utilized atomic layer deposition to selectively functionalize battery materials.

The technology

Atomic layer deposition (ALD) is a modified process of chemical vapor deposition. The characteristics of the process are two successive self-limiting surface reactions which allow the deposition of extremely thin, defect-free and exceptionally homogeneous layers. These advantages of ALD technology are increasingly being exploited in other industries, such as battery technology.

Current challenges in battery technology

Current challenges in battery technology are, firstly, to optimize the manufacturing processes of lithium-ion batteries and, secondly, to develop appropriate processes for new types of energy storage technologies such as all-solid-state batteries (ASSB). In both cases, material, process and production parameters must correlate with the electrochemical performance, i.e. the desired performance characteristics of the batteries. All steps of the entire process chain ultimately influence the product properties: material production and assembly as well as mixing and dispersing, the extrusion of electrode suspensions, and coating and calendering. A decisive factor is thereby presented by the interfaces between the deployed materials and components. Depending on the cell chemistry, these interfaces are subjected to differing requirements. A targeted functionalization of the surfaces by means of atomic layer deposition allows a corresponding adaptation.

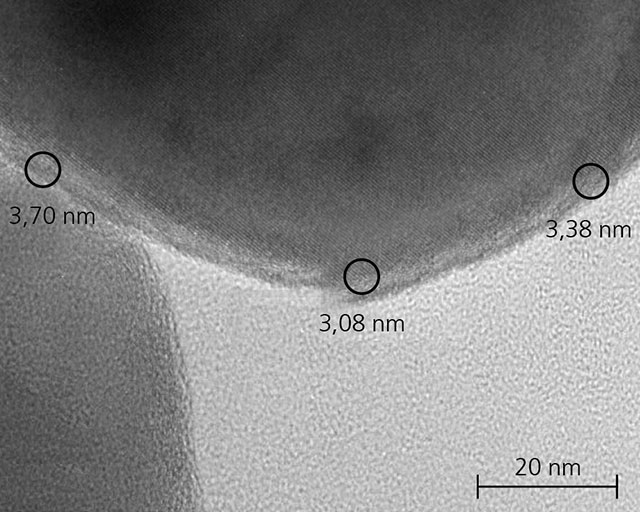

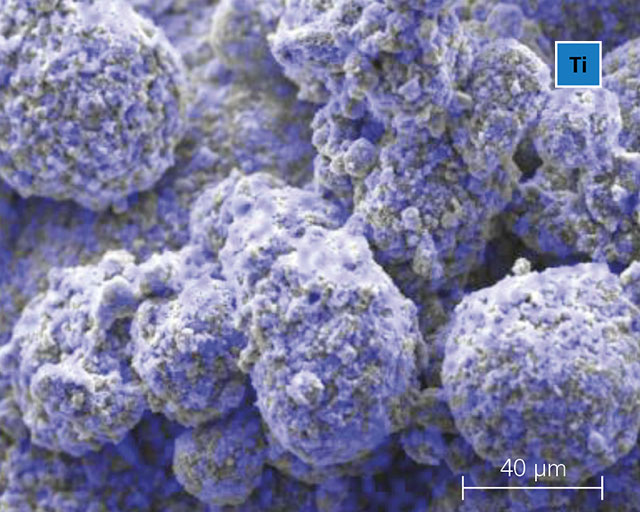

One example is the coating of composite materials by means of ALD as shown in the adjacent Figure above left. Through the coating, it was possible to improve the flow properties of the granulates under the given conditions, thereby simplifying the processability. Furthermore, the coating material has a positive effect on the resulting cell properties.

ALD in battery technology

The fields of application for ALD in battery technology range from the functionalization of particulate materials such as active materials and granulates through to layer structures such as electrodes. Through the targeted application of functionalities, various effects can be achieved, such as the reduction of interfacial resistances, the improvement of the chemical resistance, and enhanced adhesion properties.

This article is part of the annual report 2019.