Plasma coating of particle surfaces

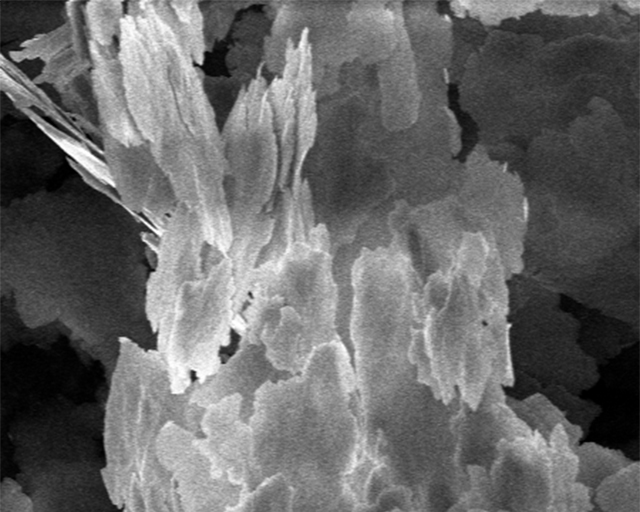

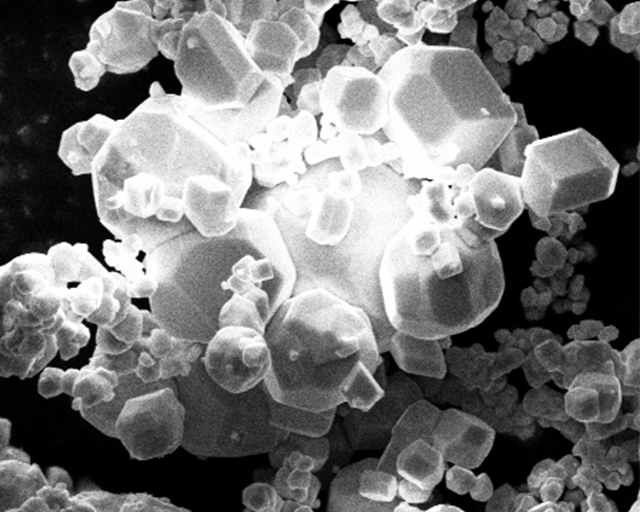

Particle coating for multi-component systems

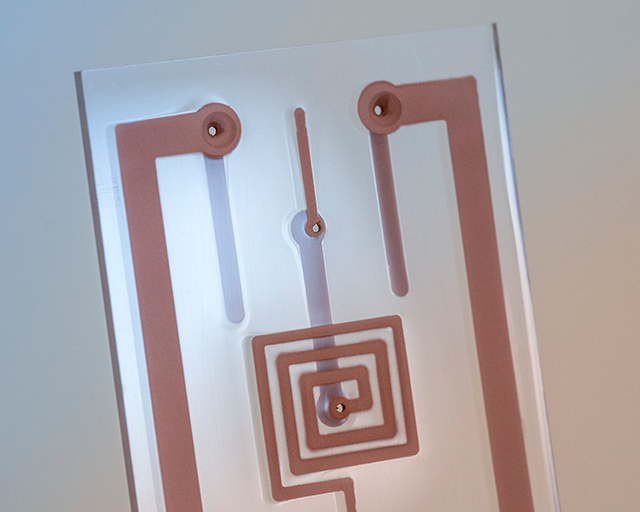

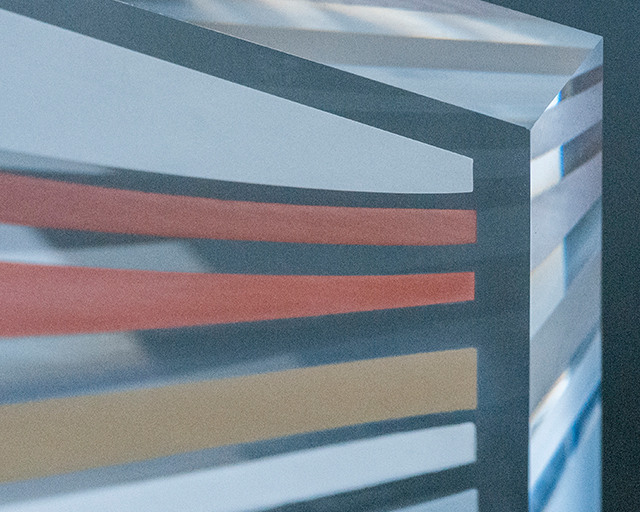

The chemical composition of a coating can be significantly influenced by the starting materials. Through the utilization of modified particles, which e.g. have a core or shell structure, multi-component systems or multi-component layers with new properties can be created.

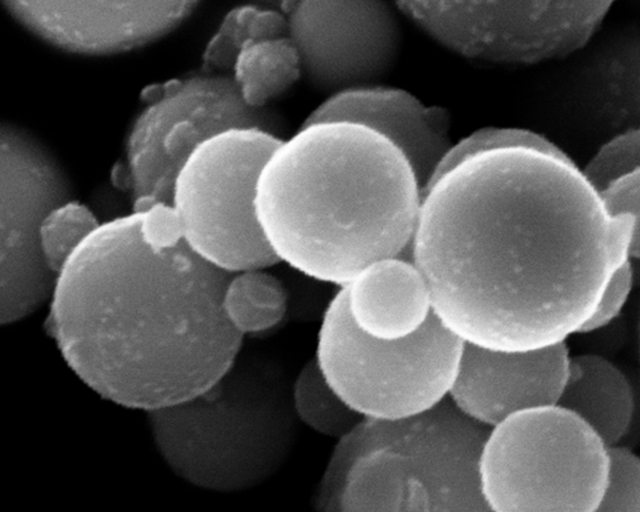

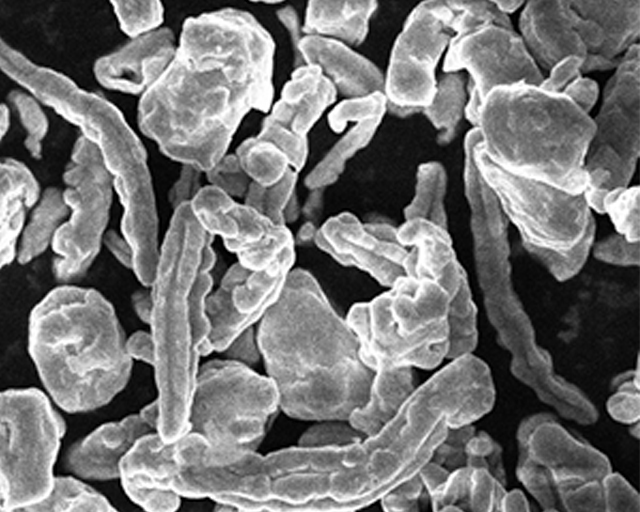

Particle modification for cold plasma spraying and 3D printing

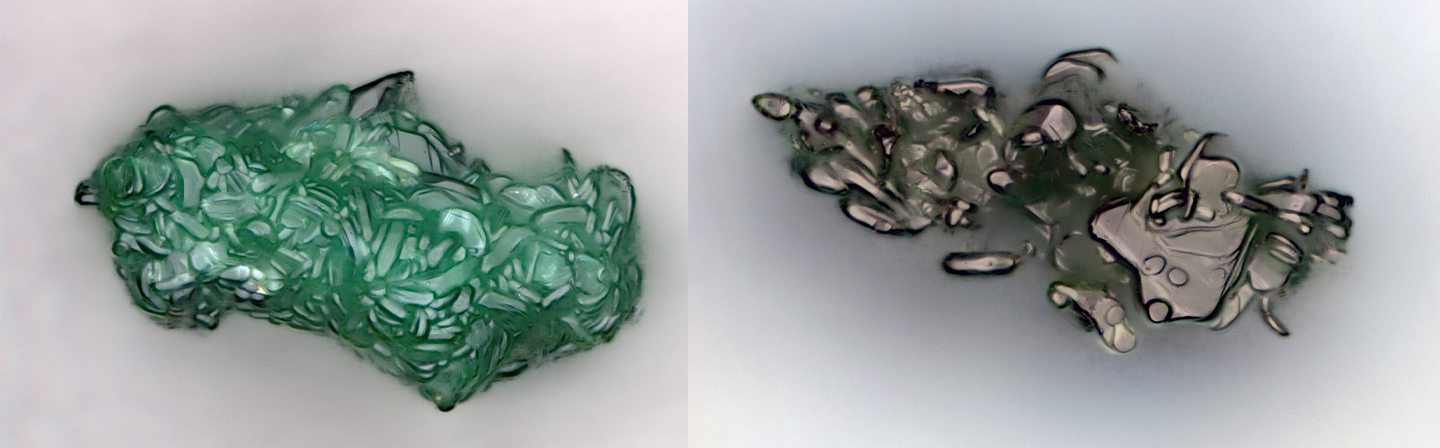

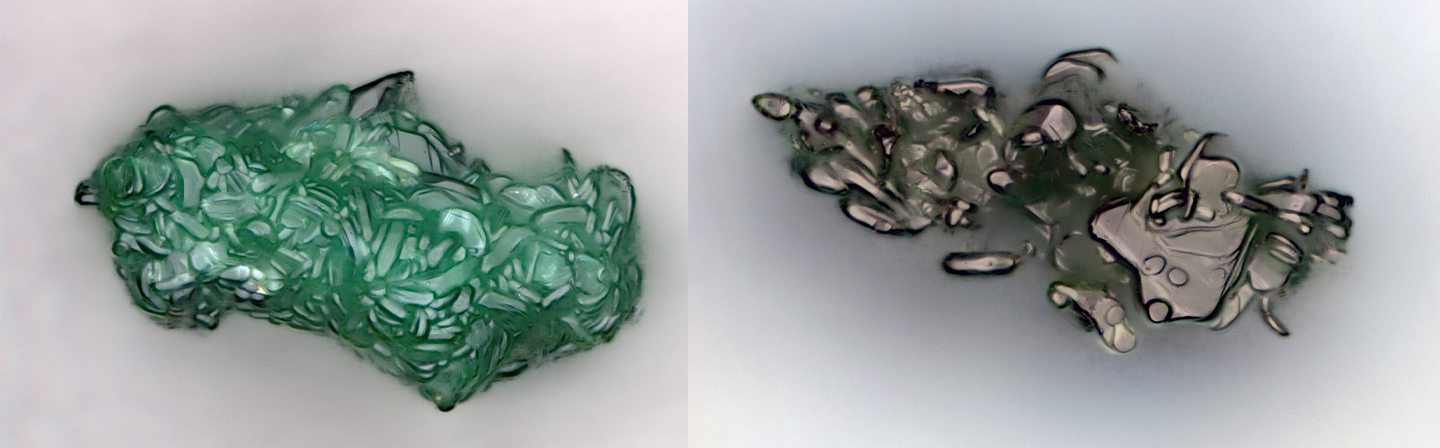

The chemical or physical and morphological properties have a significant influence on the potential spraying capabilities and the resulting coatings. In the special application case of cold plasma spraying in the field of atmospheric plasma spraying, limitations exist in comparison to the conventional thermal spraying process with regard to the low temperature input. In order to nevertheless be able to deposit high-melting materials, one approach is the use of nanoscale particles. Stable particle aerosols necessary for this can be provided.