Metal diffusion

Metal diffusion systematically expands the application range of materials

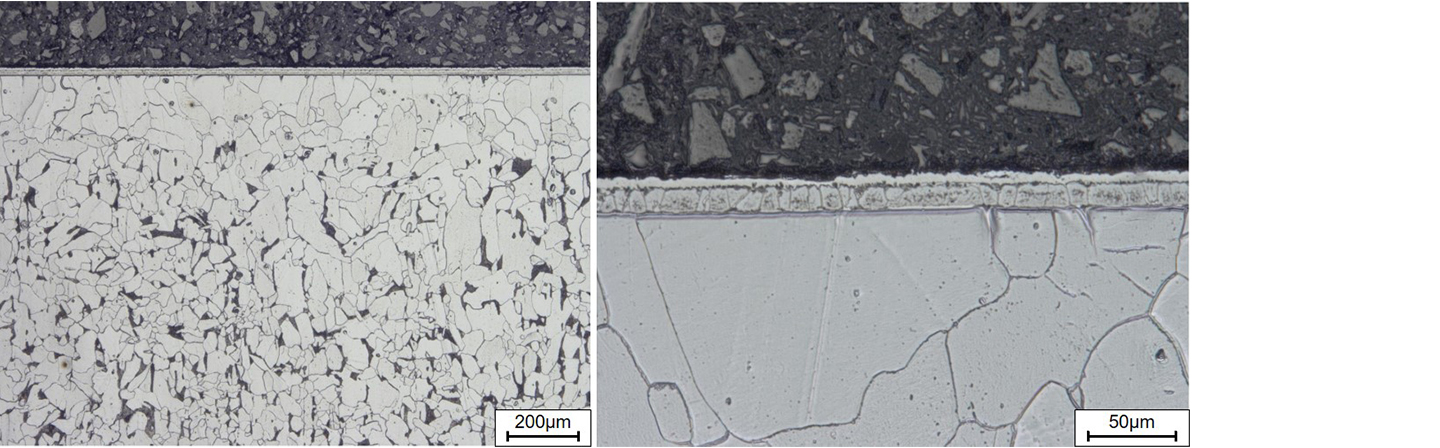

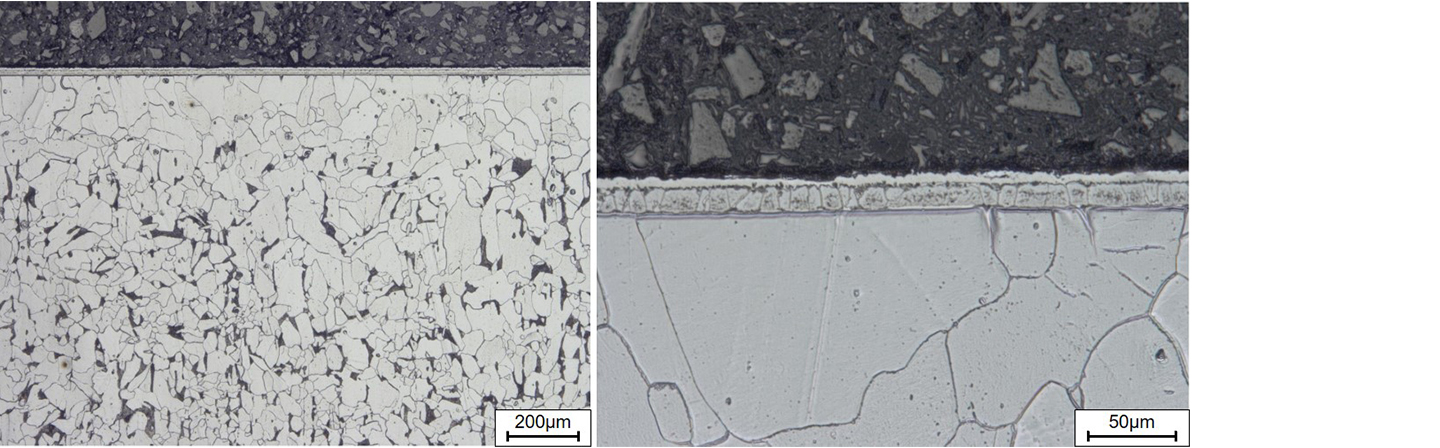

Metal diffusion is a procedure for modifying the edge-zone properties of metallic materials. In this procedure, diffusion processes occur between a substrate and a previously applied metallic layer by means of a subsequent heat treatment. The modification enables a more specific adjustment of edge-zone properties than is currently possible with classical diffusion procedures. The focus is on hardness as well as protection against carburization and oxidation. With this alternative treatment method, new problems in the industry can be solved.

Protection against external conditions – through the power of the elements

With the aid of metal diffusion, materials in the edge region can be specifically adjusted to suit their subsequent property profile. Low-alloy steels can, for example, be utilized in areas of application in which their usage would originally have been inconceivable. Differing alloying elements can increase strength, reduce tempering embrittlement or increase oxidation resistance. Through the appropriate selection of elements, the property is significantly altered.