Surface functionalization: Precisely fitting bone implants from the printer

Cancerous tumors, infections or bad fractures can make it necessary to surgically remove bones and insert implants in their place. In collaboration with European partners, Fraunhofer researchers have now developed a technique with which bone implants that are precisely fitting, stable and variable in dimensions can be 3D-printed from a special plastic. The secret lies in the printing process, where the individual layers are treated with a cold plasma in order to improve the bonding of bone-forming cells.

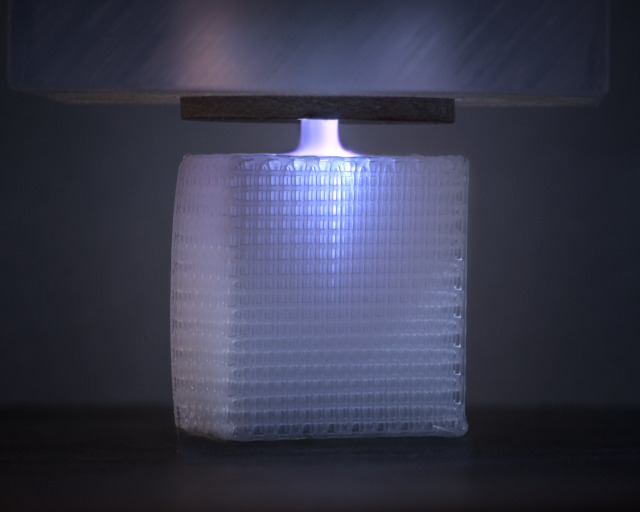

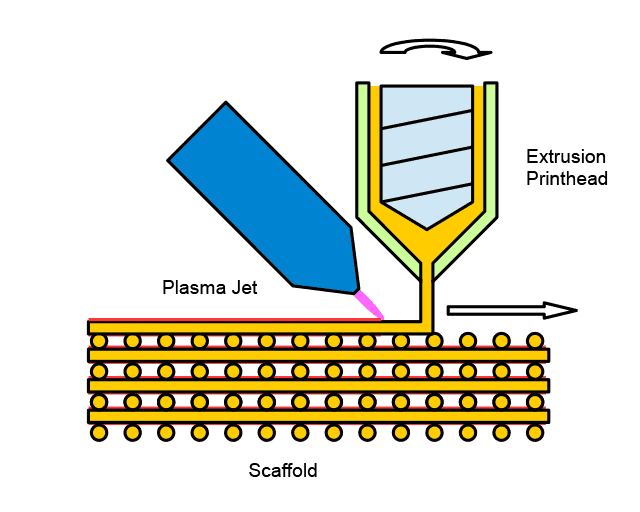

Whereas conventional surface treatments using low-pressure or atmospheric pressure techniques have a limited penetration into the interior of bone implants, the new method makes it possible to apply a cell-growth-promoting coating also to the interior of the implants. To this end, the team of researchers at the Fraunhofer Institute for Surface Engineering and Thin Films IST uses a plasma jet. The device blows a cold jet of plasma containing reactive groups directly onto the printed layers. The amino groups bond with the surface and ensure that bone cells find a convenient substrate to which they readily adhere. A unique feature of the technique is that the 3D printing and coating processes go hand in hand and are combined in one device. Because no chemical pretreatment with solvents is required for the coating, it is not only cost-effective, but environmentally friendly also.

The scaffold around which the implant is built is made from a special copolymer that is modeled on the natural bone. The 3D printing technique permits very individual, precisely fitting design and stability. “Our goal is for the bone cells to grow into the synthetic structure as quickly as possible and finally replacing the implant which is broken down gradually by the body’s own enzymes,” explains Dr. Jochen Borris, who heads up the Life Science and Ecology business unit at Fraunhofer IST.

Variable thanks to sophisticated fillers

The mechanical stability of the implant can be controlled not only via the density of the printed scaffold structure, but also via special fillers that are added to the copolymer: the higher the filler concentration, the greater the stability. “This development by our project partners from Maastricht University makes it possible to individually vary the stability inside the implant. Like natural bones, implants can now have areas with different strengths,” says Dr. Thomas Neubert, manager of the EU project at Fraunhofer IST.

Moreover, active drug ingredients such as antibiotics can be incorporated in the filler to reduce the risk of infection. The project team has successfully completed the project steps to date; now it plans to modify the technique and bring it to application maturity. At present, the experimental set-up is still on a laboratory scale.

“We’re currently working on simplifying the process and making it more stable. To be able to further pursue development and carry out clinical studies, we’re on the search for industrial partners,” says Borris. The innovative technique offers a lot of potential for adapting bone implants very precisely to the individual needs of patients. “With our method, we’re able to control the shape, porosity, mechanical stability and biomechanical characteristics well and vary them within the implants. This means that we can produce areas with different strengths or porosities, which can also be coated with various functional groups.” In the future, doctors could be able to formulate the requirements for each patient based on scanned images and send the data to medical print shops, where the precisely fitting implants would then be printed.

The FAST project at a glance

Eight European companies and research institutes have teamed up in the EU-funded research and innovation project “FAST”, which stands for “Functionally graded Additive Manufacturing (AM) scaffolds by hybrid manufacturing”, to make a new 3D printing technology available for the manufacture of implants customized to the patient at affordable cost.

Project partners

- Abalonyx AS, Norway

- Fraunhofer Institute for Surface Engineering and Thin Films IST, Germany

- Fundacion Tecnalia Research & Innovation, Spain

- GeSIM Gesellschaft für Silizium-Mikrosysteme mbH, Germany

- Maastricht University, The Netherlands

- Nadir Srl, Italy

- Polyvation BV, The Netherlands

- Prolabin & Tefarm S. r. l., Italy

- University of Padova, Italy

Further information:

http://project-fast.eu/en/home

Last modified: