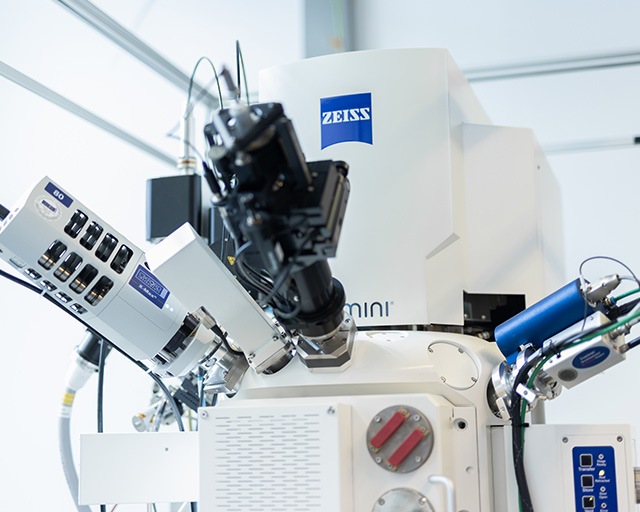

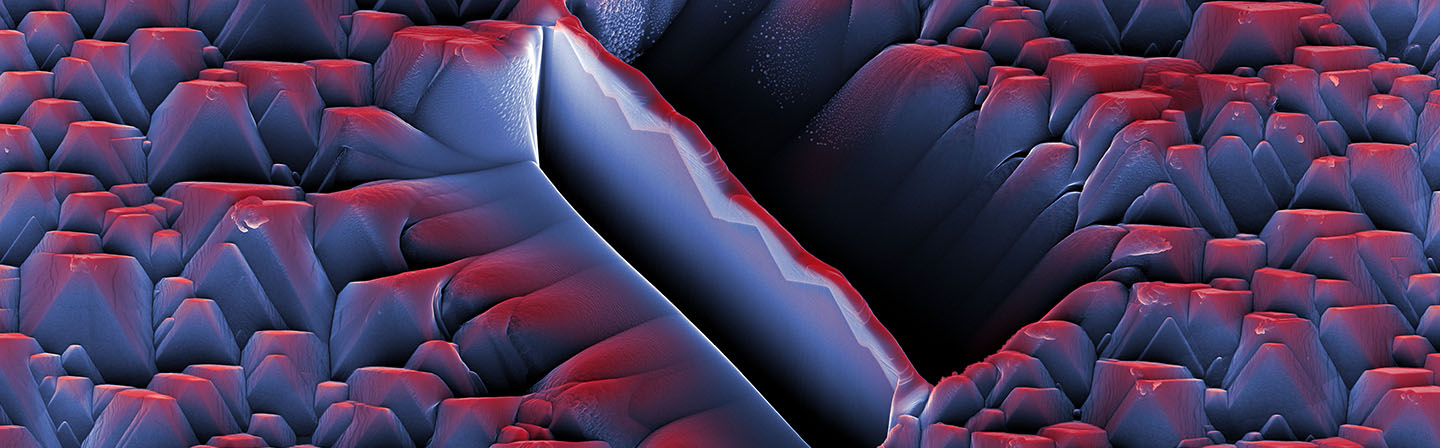

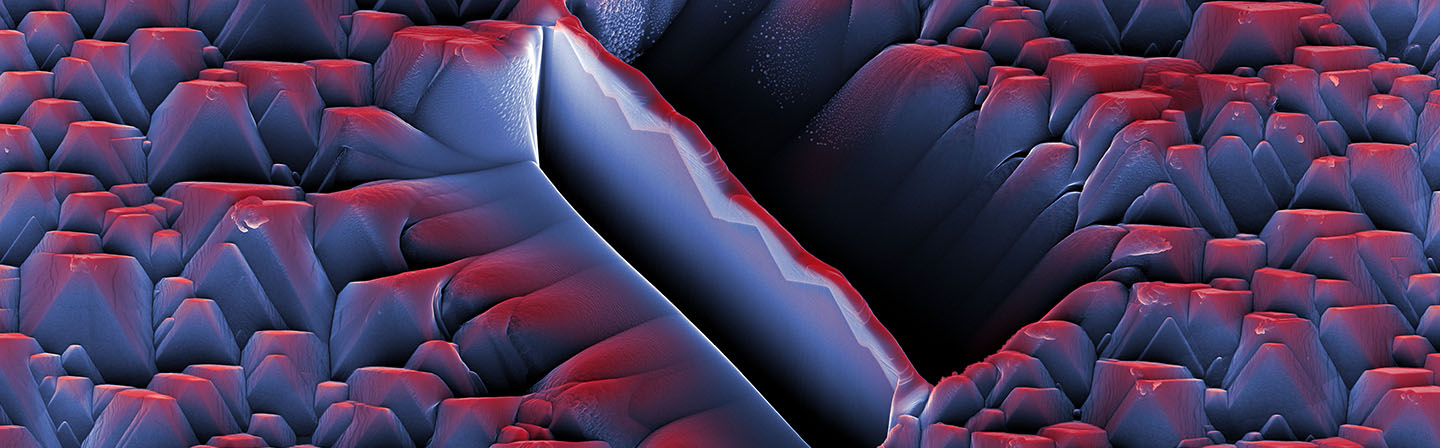

Targeted material cross-sections on the microscale using Focussed Ion Beam (FIB)

Functionality of the Focussed Ion Beam (FIB)

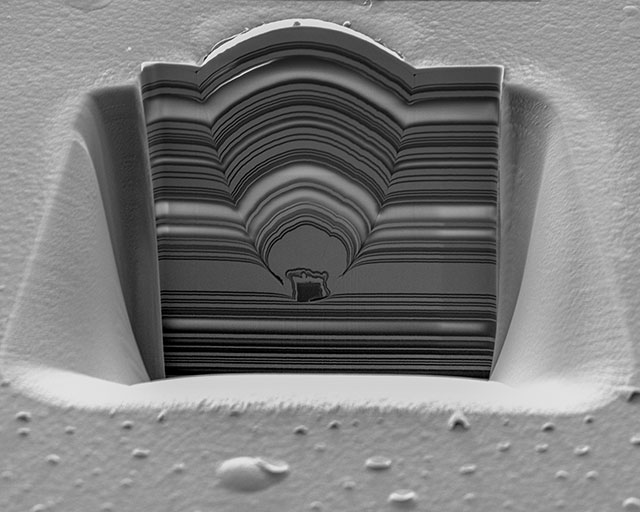

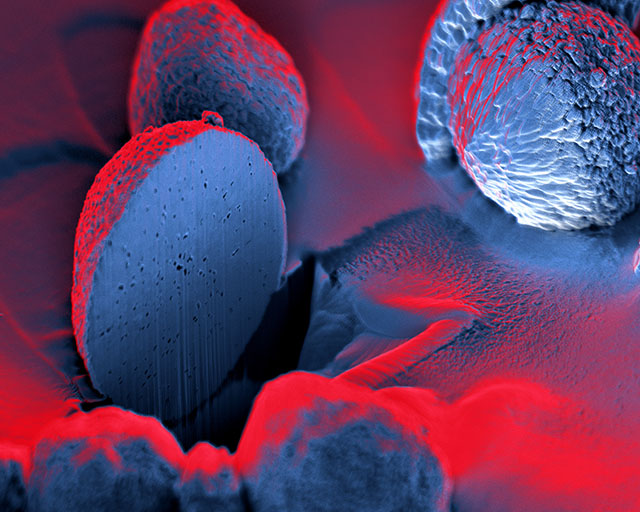

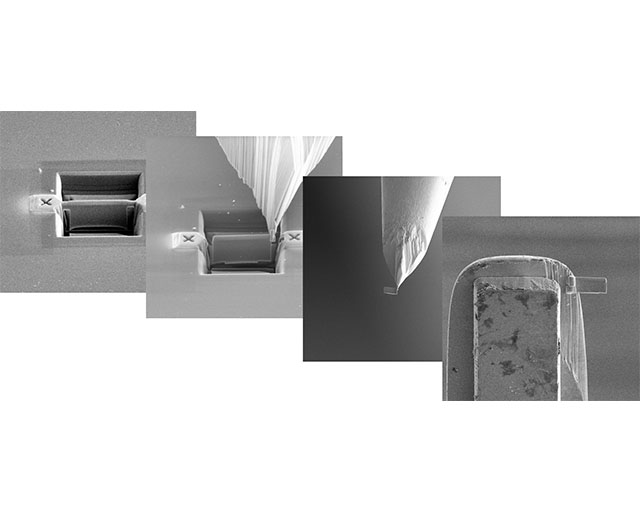

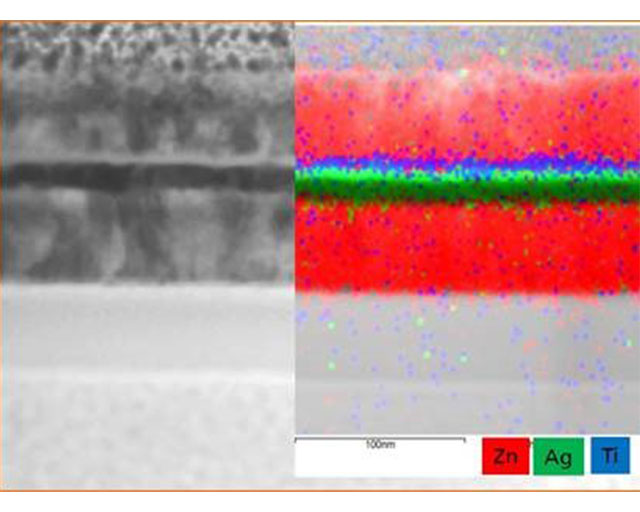

The combination of scanning electron microscope (SEM) and focused ion beam (FIB) makes it possible to specifically cut into material on the smallest scale (nanometer range) and directly image the material structure below the surface. This allows, for example, the precise localisation and chemical analysis (EDX) of local faults. This works for almost any material in a solid state, whether soft or extra hard, polymers, metals, ceramics, textile fibers, wood, etc.c.

Areas of use

- Local cross-sections e.g. at defect sites such as thin-layer growth defects, corrosion, trapped particles, etc.

- TEM lamella preparation

- High-resolution cross-sectional investigations in transmission (STEM)

- 3D tomography of the microstructure or local defects

- Writing of structures by means of targeted material removal

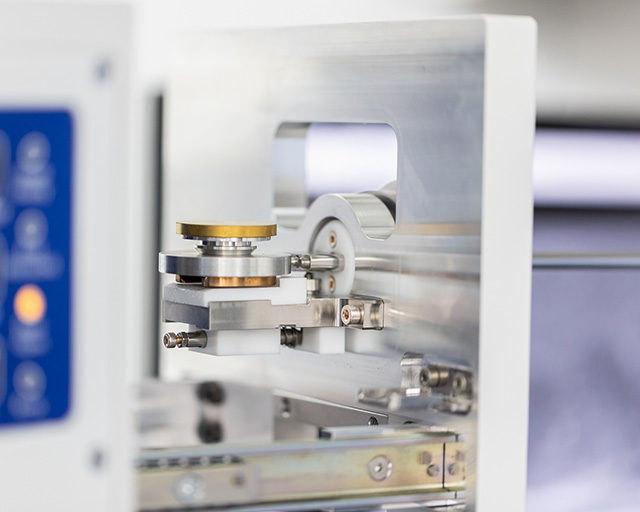

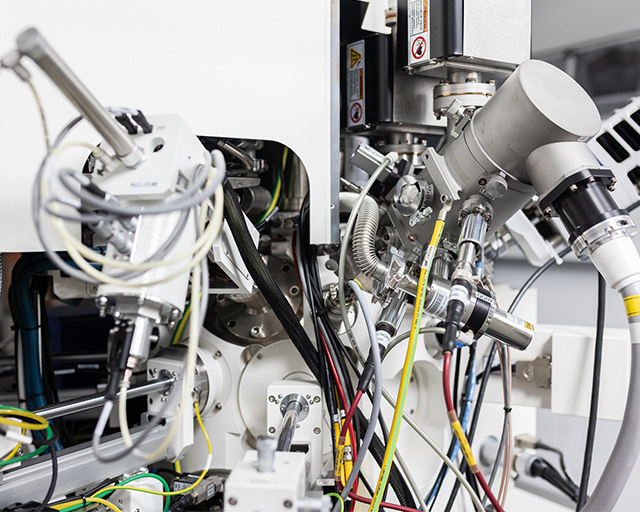

The Focussed Ion Beam (FIB) device ”Cross-Beam 340” from Zeiss is used for the preparation of local cross sections and TEM lamellae. Equipment: Ga ion source (1-30keV), FE Schottky emitter, detectors: In-Lense, SE, BSE, STEM and EDX, micromanipulator, PtC precursor, variable pressure mode, plasma cleaner, large airlock.