Abrasive wear-testing of surfaces

The crater grinding wear test (DIN EN 1071-6, EN ISO 26423)

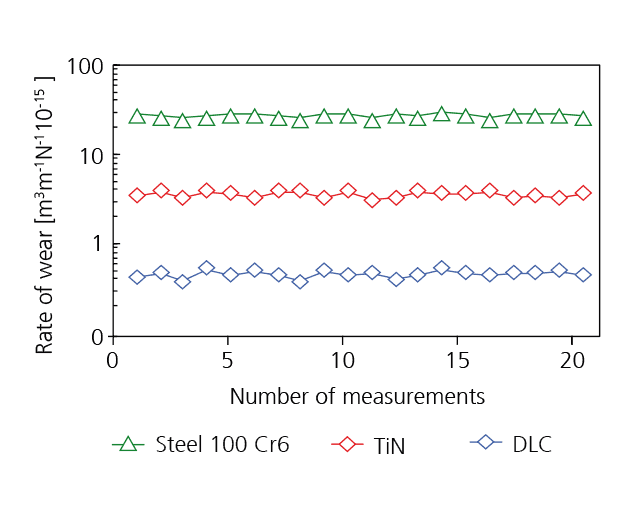

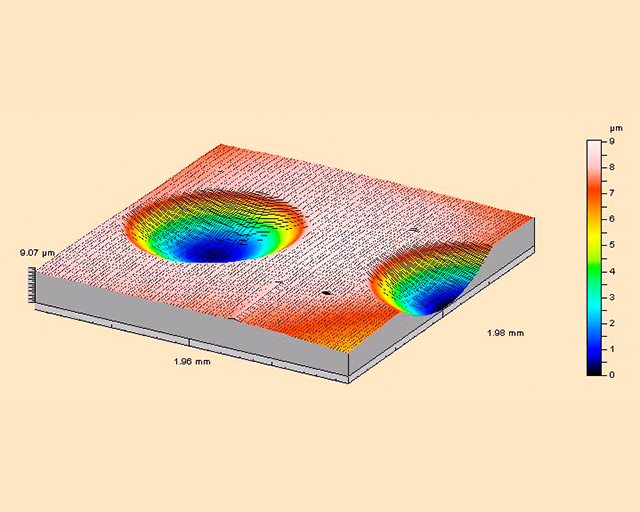

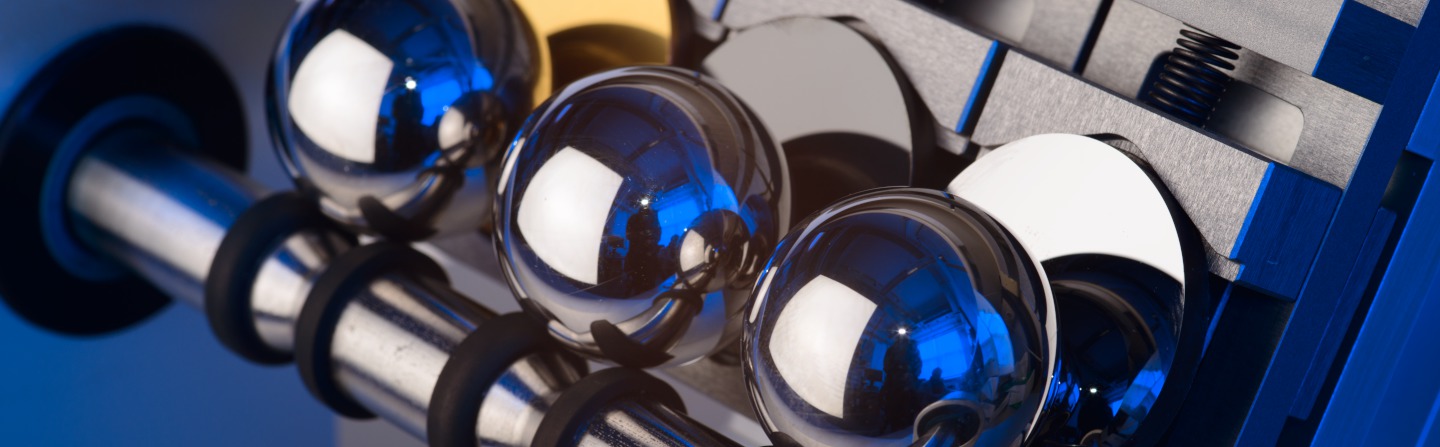

The crater grinding method can be used to precisely determine the wear resistance of coatings and surfaces. A steel ball wetted with an abrasive fluid and rotating against the specimen grinds a crater into the layer to be tested. The wear coefficient can be calculated from the volume of the crater.

Application in quality assurance

The method is suitable for testing coatings with thicknesses ≥ 1 μm. Abrasive wear is very sensitive to changes in coating composition and structure. It can therefore be used as a parameter for evaluating coating quality in production and for optimization during the development of coating systems.

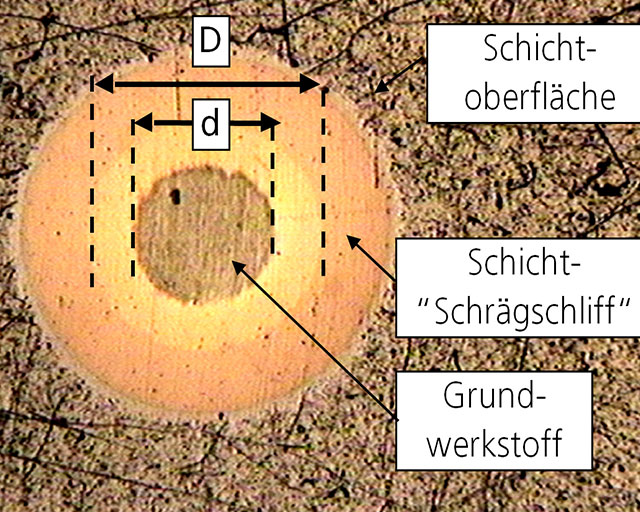

If the crater is ground through the layers into the substrate, the thickness of the layers can be determined from the diameters of the rings. The accuracy of the coating thickness measurement is approx. 0.1 µm, depending on the surface.

Crater wear (abrasive)

Calotte crater

Crater grinding for determining layer thickness

If the crater is ground through the layers into the substrate, the thickness of the layers can be determined from the diameters of the rings. The layer thickness t is then given by the formula: t = (D2-d2)/8R, where D, d = outer and inner ring diameters and R is the sphere radius. The accuracy of the coating thickness measurement is approx. 0.1 µm, depending on the surface. µm.