#WeKnowHow – The Fraunhofer IST vs. Corona

The corona pandemic has changed the world and confronts us with major challenges in many areas. The Fraunhofer-Gesellschaft has launched the “Fraunhofer vs. Corona” action program in order to pool the diverse proficiencies of the institutes Fraunhofer-wide and, in so doing, to contribute towards mastering the direct and indirect consequences resulting from the SARS-CoV-2 virus. With its expertise in process-engineering and manufacturing technology, in particular for process and application-oriented surface technology, the Fraunhofer IST is addressing the corresponding solution approaches in the fields of protective textiles, medicine, and hygiene and disinfection.

Surface technology for medical solutions

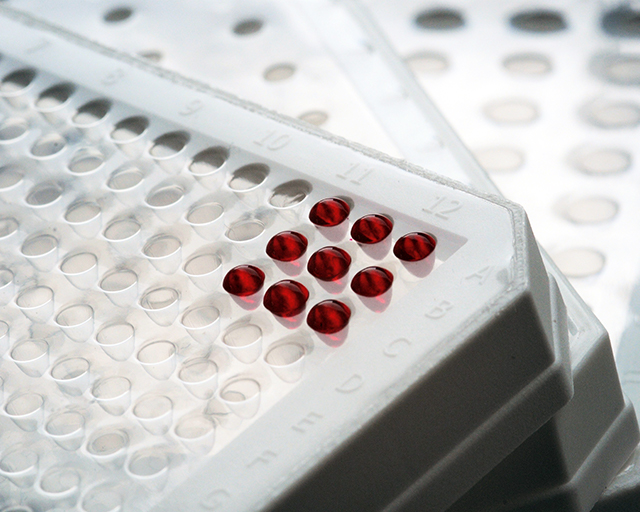

Reliable tests for the rapid determination of a SARS-CoV-2 infection are an important building block in the fight against the corona pandemic. In cooperation with the Städtisches Klinikum Braunschweig (Braunschweig Municipal Hospital), the Fraunhofer IST is participating in the further development of ultra-fast PCR tests. For such “disposables”, which are needed in quantities of millions, the manufacturing costs are a decisive factor. The IST researchers are thereby optimizing the films utilized in the test by means of a spatially selective functionalization of the surface by means of plasma technology. In this way, the films can be made locally wettable in such a way that the sensitivity of the fluorescence-based diagnosis is increased, as a result of which the accuracy and reliability of the test systems are enhanced.

Surface technology can also play a significant role in medical care. Patients with a severe case of COVID-19 illness, which, in most cases, is accompanied by pneumonia, often require artificial respiration. In order to determine at what point artificial respiration becomes necessary and how long non-invasive respiration will suffice, reliable respiratory monitoring is necessary. Furthermore, affected patients and also medical staff should be protected against viral infection to the greatest extent possible. In cooperation with two Fraunhofer institutes and industrial partners, the Fraunhofer IST is therefore working on a smart virus filter – an innovative combination of fast sensor elements for measuring respiratory flow, pressure and respiratory gas together with a filter. The Fraunhofer IST is hereby concentrating on the development of a manufacturing technique for thin-film sensors for pressure measurement which are inexpensive to produce and which can be easily integrated.

Protective textiles – sustainable and antiviral

At the beginning of the corona pandemic, there was a lack of suitable protective clothing as well as face masks with FFP2 and FFP3 classification for medical personnel and nursing staff. The need for high-quality protective masks remains particularly acute. Optimal disinfection of masks represents a sustainable and resource-saving option in order to enable multiple reuse of protective masks. In collaboration with the Städtisches Klinikum Braunschweig, the Fraunhofer IST therefore investigated suitable test methods which, in addition to sterilization effects, can also be used to test particle permeability and the impermeability of the material following sterilization.

Functional protective clothing which, in addition to its protective function, also kills viruses and other germs offers both medical and nursing staff improved protection against infection. In collaboration with eight other Fraunhofer institutes, the focus is being directed on the development and testing of novel carbon-based coatings for antiviral protective textiles. For this purpose, innovative materials and process-engineering approaches of gas-phase-based coating processes are being investigated at the Fraunhofer IST. The coatings produced in this way are validated regarding their anti-microbial functionality and mechanical stability. The aim is to establish a sustainable, scalable and reliable manufacturing process for the antiviral finishing of textile materials.

Disinfection and cleaning

In times of crisis and disaster, such as the corona pandemic, mobile, decentralized systems for cleaning and for the provision of disinfectants in the medical care of the population can be a crucial supplement to the health infrastructure. With this in mind, a team from six Fraunhofer institutes is developing an integrated system of mobile, decentralized medical care. Drawing on its experience in decentralized and autonomous water treatment, the Fraunhofer IST is working on a system for surface disinfection which can make disinfectants directly available via a spray system by means of diamond electrodes or plasma processes. This system is intended to be used autonomously for surface sterilization and can be deployed, for example, in a mobile test platform which can also be utilized in emerging and developing countries.

Furthermore, the Fraunhofer IST is also conducting research within a Fraunhofer team on technologies for mobile disinfection robots which disinfect potentially contaminated surfaces in public buildings or on public transport in a targeted, efficient and gentle manner. The focus of the IST’s work lies thereby on the development of miniaturized plasma systems and their integration into the disinfection robots as well as on the investigation and evaluation of material damage caused by the various cleaning tools such as plasma, UV-C or aqueous cleaning.

In the field of mobile disinfection, a further objective of the Fraunhofer IST is the development of a mobile room-air cleaning system. This device is intended to effectively destroy viruses, bacteria and fungi in the room air in order to reduce the risk of infection. The Fraunhofer IST is therefore working on the calculation and simulation of the flow dynamics of bioaerosols in indoor areas. On the basis of these results, the development of a regulated plasma air purifier should be made possible.

Outlook

The process-engineering and manufacturing solutions based on plasma and surface technology addressed within the anti-corona projects lay the foundation for future work on combating infectious diseases. As a result, in the future it will be possible in the medical sector to utilize functional coatings with antimicrobial efficacy and cleaning technologies for the automated and active combatting of infectious agents in order to prevent the spread of or immediately disinfect microbial contaminations. Through the optimization of medical technology solutions in diagnostic testing and monitoring systems, improved patient care will be established in the long term. Sustainability and resource-saving processes hereby play a decisive role. Here at the Fraunhofer IST, the appropriate demonstrators are being created, which, in the next step, will be optimized in collaboration with industrial partners and subsequently transferred to the application.

This article is part of the annual report 2020.