Air cleaning to reduce aerosol-borne germs

Cleaning of room air by means of plasma

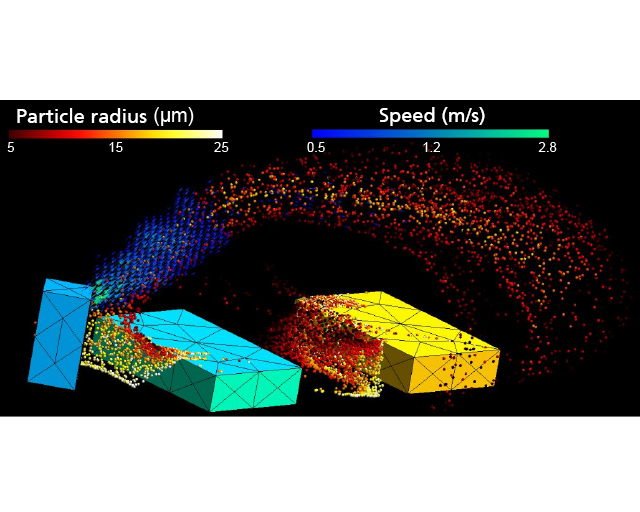

The rapid transmission of infectious diseases through airborne germs such as the SARS-CoV-2 virus is particularly problematic in closed rooms. The development of new and practical solutions for the purification of indoor air has been accelerated, particularly in connection with the COVID-19 pandemic. Researchers from the field of plasma and surface technology at the Fraunhofer IST, in collaboration with the HAWK Göttingen and the Fraunhofer WKI, have developed an air purifier which combines the advantages of plasma, UV-C and photocatalysis, fulfills the function of air cleaning and, at the same time, enables surface disinfection, for example in hospital rooms.

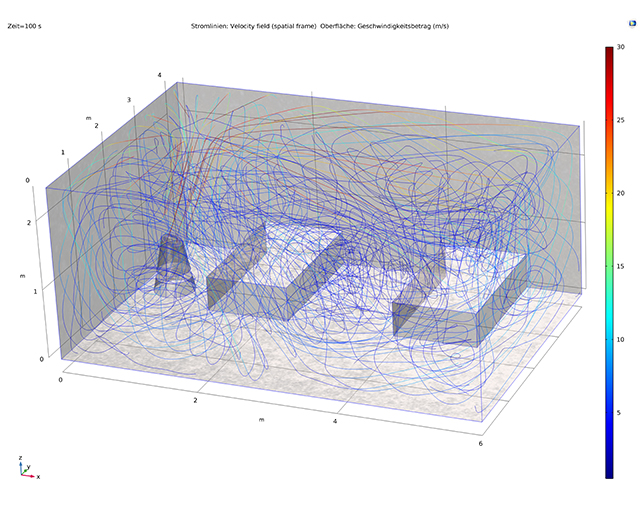

Combining expertise in plasma technology, surface technology and simulation

The active principle is based on the combination of a number of physical methods in two different process modes: the direct cleaning of the room air as a result of flowing through the air purifier, and the cleaning and disinfection of the surfaces in the patient’s room by means of released ozone. The latter is automated without the presence of people in the room. In the design and optimization of the air purifier, flow simulations played a significant role. The air purifier will be tested and further optimized in the patient room of the future.