Thermodynamic modeling of alloys using the CALPHAD method

Modeling of thermodynamic processes and diffusion in metal parts

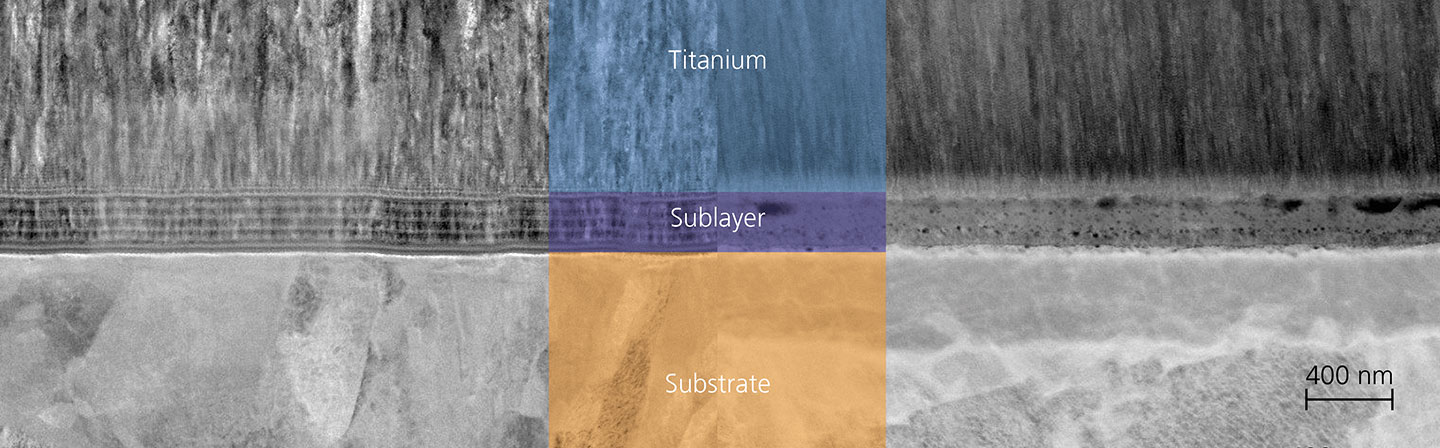

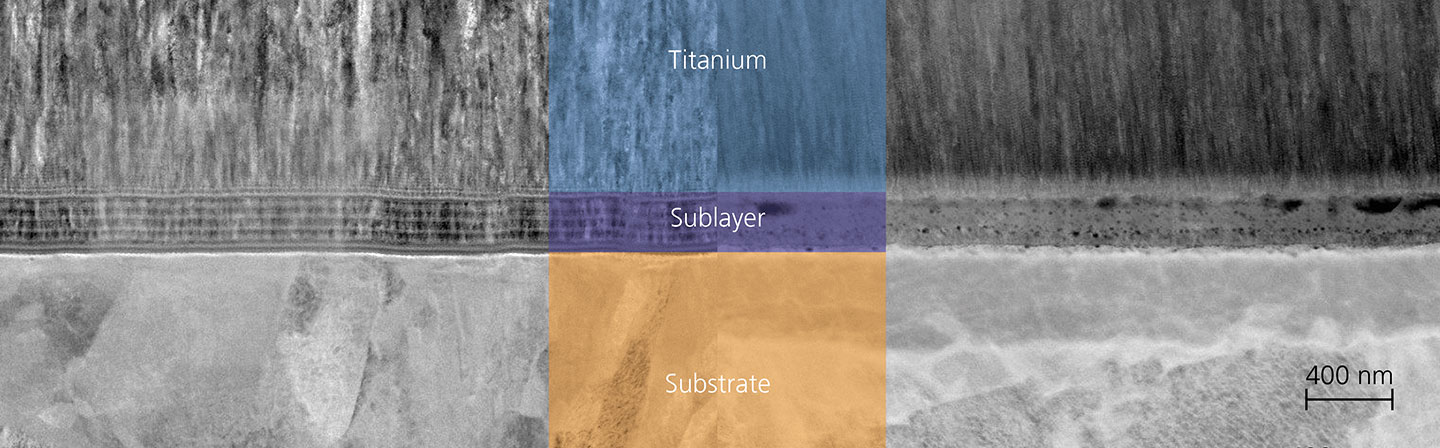

Thermodynamic modelling of metal parts during plasma diffusion or electron beam treatment yields predictions of alloy composition and structual changes close to their surface. This information enables to tailor machining processes with respect to optimized mechanical component properties. Fraunhofer IST offers experience in thermocynamical modelling via the CALPHAD method and the software packages Thermocalc and DICTRA.

Optimization of diffusion and deposition processes with respect to mechanical performance of parts

The CALPHAD method allows to identify parameter windows in machining processes such as plasma diffusion or electron beam treatment, that enable to ensure the specified alloy composition and mechanical performance. For the development of new component and material compositions, the number of experimental trials can be minimized via thermodynamical simulation studies.