Sensor technology for temperature measurement in mixed-friction-loaded contacts

For the optimization of partially or fully lubricated tribological systems, knowledge concerning the temperature in the lubrication gap is of great importance. In order to be able to create a better design for the scuffing load capacity of gear teeth, the temperature in the mixed-friction-loaded tooth-flank contact must be measured. Whilst thin-film sensor systems are suitable for this purpose, they are, however, subjected to very high wear in these contact zones. Within the framework of an AiF research project (No. 19330 BG), the Fraunhofer IST, in collaboration with its partners, is therefore developing a wear-resistant thin-film sensor system for long-term stable temperature measurement in tooth-flank contacts which are subject to mixed-friction loading.

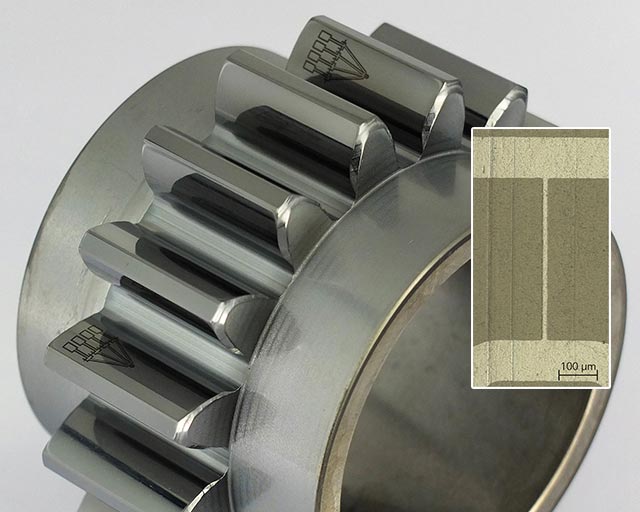

Film system with integrated temperature sensors

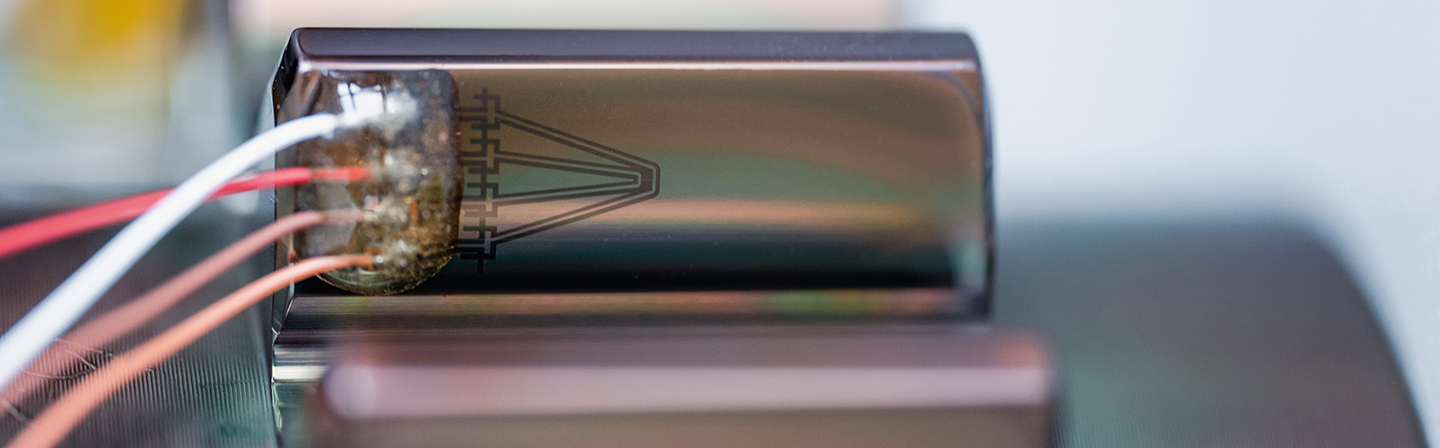

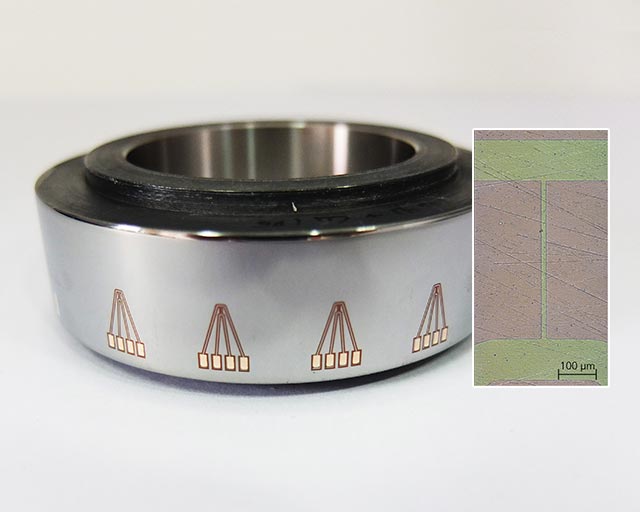

The thin-film system is built-up directly on the polished surfaces of steel rings and gear-tooth flanks (Rz value of 0.1 µm). Aluminum oxide (Al2O3) is homogeneously deposited as a base layer in the form of an electrical insulation layer with a thickness of 4 – 6 µm. Subsequently, the samples are coated with 200 nm-thick chromium, which is structured using a combination of photolithography and wet-chemical etching. A steel ring with sensor structures is presented in the adjacent Figure, whilst the Figure above shows a gear wheel. Over the course of the project, it was possible to considerably reduce the minimum structure width down to 10 µm (see in the two adjacent Figures), which results in a high spatial resolution and sensitivity of the sensors. In conclusion, a 1 – 2 µm-thick layer of SiCON®, an amorphous hydrocarbon layer modified with silicon and oxygen (a-C:H:Si:O), is applied as an insulation and wear-protection layer. The thin-film system for temperature measurement in mixed-friction-loaded contacts thereby has a thickness of less than 10 µm.

Characterization of the sensor structures

To record the thermoresistive resistance characteristics, the sensors are measured in a so-called four-wire circuit, i. e. a constant current is applied via two supply cables, and the voltage drop across the sensor is measured via two further cables. The sensor resistance is then calculated according to Ohm’s law. During the measurement, the samples are located in a furnace, where they are initially heated to approx. 170 °C and then subsequently cooled down again to room temperature. The resistances of the individual sensor structures exhibit the linear dependence on temperature expected for metallic structures.

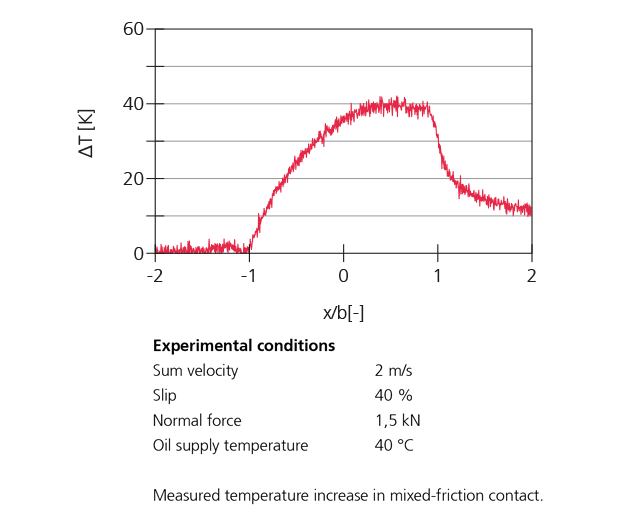

Temperature measurement in mixed-friction contact

The functionality of the thin-film sensors and their wear-resistance are tested in a series of experiments under mixed-friction conditions. The adjacent graph shows an example measurement conducted using thin-film sensors of the temperature increase when the sensor is traversed.

Outlook

In the future, the sensor system is to be further developed in such a way that pressures and gap heights can also be determined. Such a multi-sensory thin-film system could, in a next step, also be used in other contacts subject to mixed friction, such as rolling bearings, plain bearings or seals, whereby all three variables – temperature, pressure and gap height – can be measured either together or individually.

The project

The described results were achieved within the FVA project 789 I “Sensors for mixed-friction” on the topic of “Development of a robust thin-film sensor system for measuring the temperature in mixed-friction-loaded thermo-elastohydrodynamic contacts”, on which the Fraunhofer IST was working in collaboration with the Institute for Machine Design (IMK) of the Otto von Guericke University Magdeburg. The project was funded by the German Federal Ministry for Economic Affairs and Energy (BMWi) on the basis of a resolution of the German Bundestag and the German Federation of Industrial Research Associations (AiF, funding project No.: 19330BG).

This article is part of the annual report 2019.