Robust temperature sensors for warm forming

In order to better understand tool-wear processes in warm forming, the actual temperature distributions across the tool surface during the forming process must be recorded. To determine these, a forging die is coated with a thermoresistive and simultaneously wear-resistant thin-film system which, in direct contact with the glowing steel blank, measures the temperature distribution in the mold.

Structure of the temperature sensors

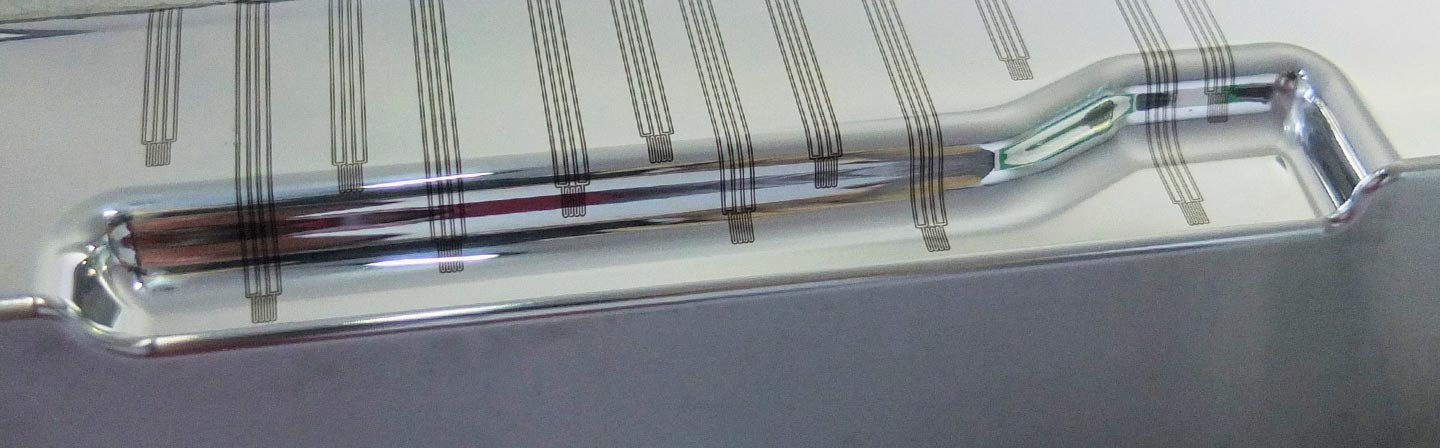

A sensory layer system is deposited on one half of the tool. Prior to receiving a primer coating of aluminum oxide (Al2O3) with a thickness of approx. 4.5 µm, the tool surface is polished in order to attain an average roughness depth of 0.1 µm. A 0.2 µm-thin chromium layer is then homogeneously deposited upon it. By means of photolithography and subsequent wet-chemical etching, the sensor structures, with their meandering shapes, are arranged in different areas of the tool. These temperature sensors, whose conductor paths run from the forming area over complex contours into the unstressed contacting area, are covered with a second 3 µm-thick insulating and wear-protecting Al2O3 layer.

Measurements in the warm process

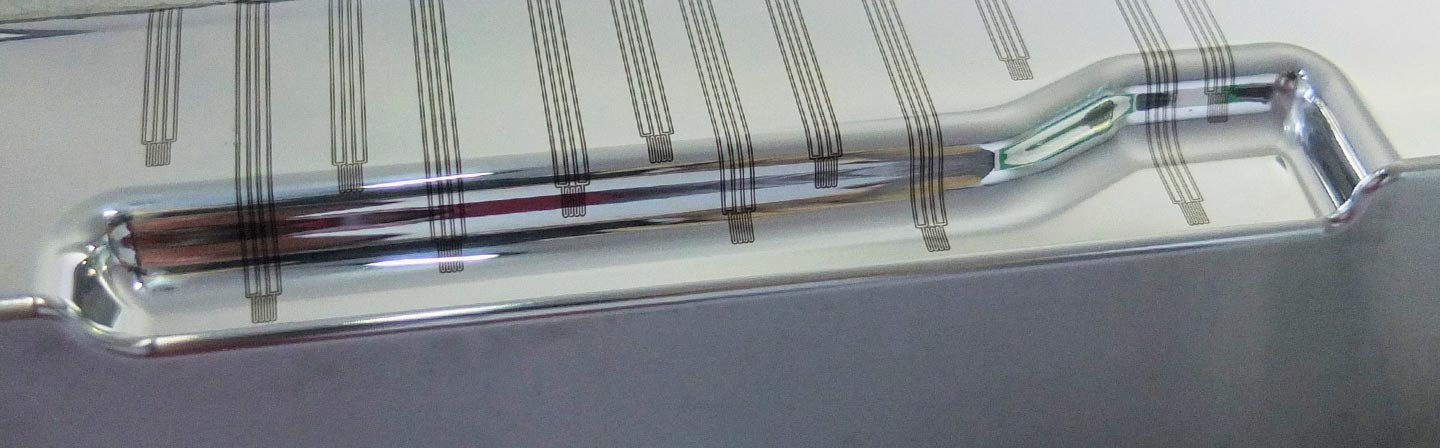

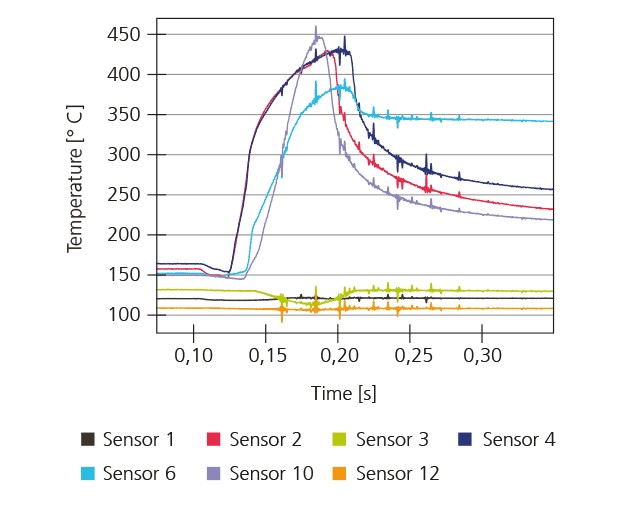

The adjacent Figure (above) shows the forging die installed in a press and equipped with temperature sensors with the glowing steel blank for warm forming. In the adjacent Figure (middle), the position of the formed workpiece in the die is presented. The individual sensor structures measure the temperature distribution via four-wire technology with spatial resolution. A corresponding measurement progression is shown in the adjacent diagram. A force of 2600 kN and a strike height of 32.5 mm were selected as process parameters.

The project

These results were achieved within the project “Warm forging of steel with carbon-based coating systems (Halbwarm DLC2)”, (funding ref. BR 2178/42-1), funded by the Deutsche Forschungsgesellschaft (German Research Foundation), in cooperation with the Institut für Integrierte Produktion Hannover gemeinnützige GmbH (IPH) and the Institute for Surface Technology IOT in Braunschweig.

This article is part of the annual report 2019.