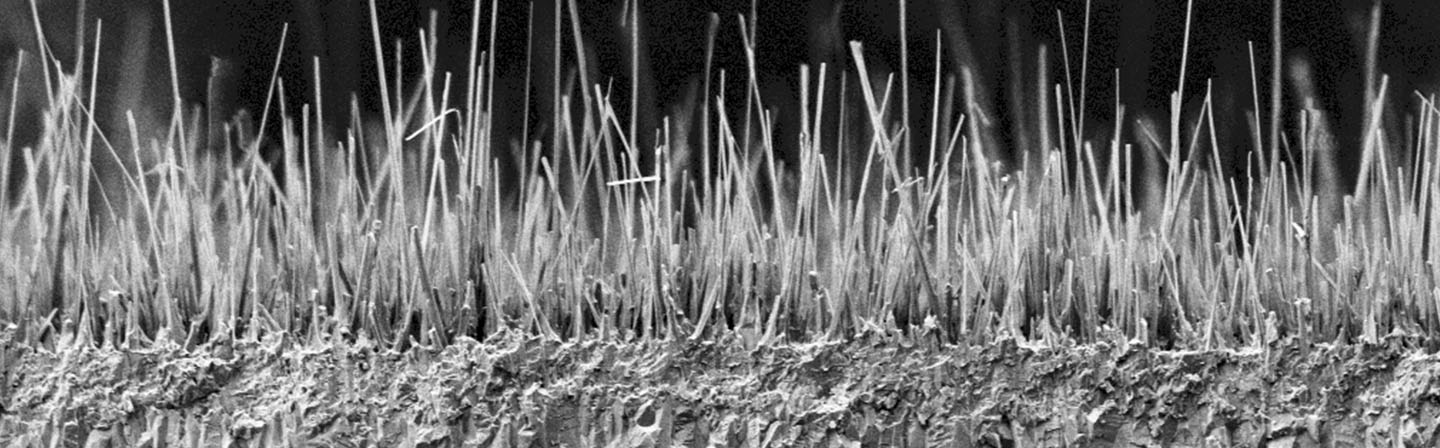

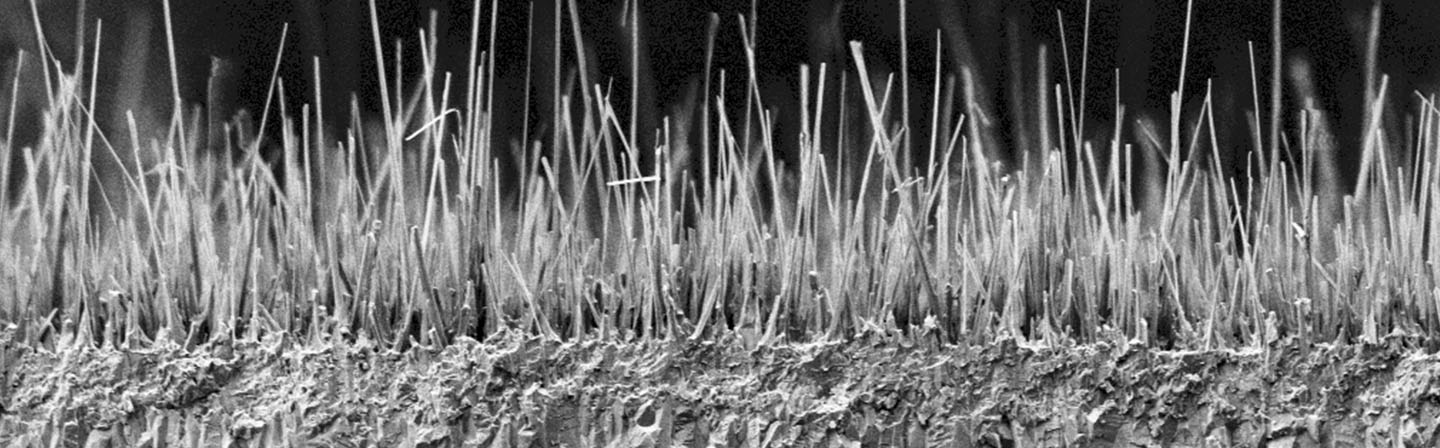

High-resolution surface imaging using scanning electron microscopy: SEM

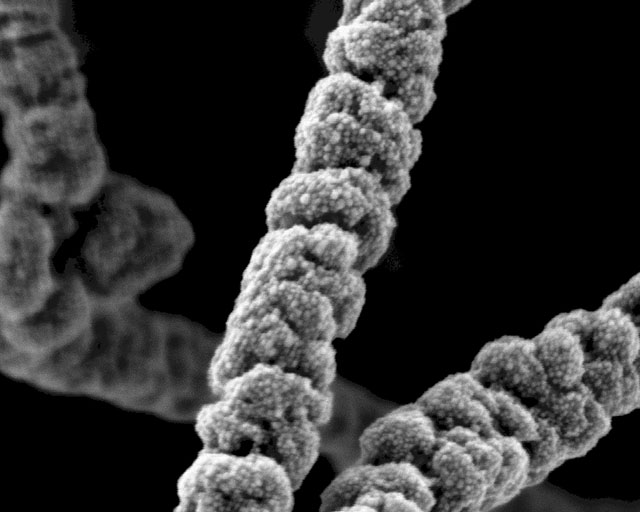

SEM image of a fracture edge with copper whiskers.

Scanning electron microscopy in materials analysis

Scanning electron microscopy (SEM) allows the imaging of surfaces, fracture surfaces or transverse sections with high resolution (2 - 5 nm) and high depth of field. It is a versatile tool that permits movement through the magnification range by a factor of 20 to 200,000 times within seconds, quick changes from one sample to the next, and the imaging of non-conductive surfaces using vapor deposition. In combination with X-ray spectroscopy (EDX), SEM analysis is the ideal tool for damage analysis, as it combines microscopic visualization and chemical point analysis.

Special analysis methods on the scanning electron microscope (SEM)

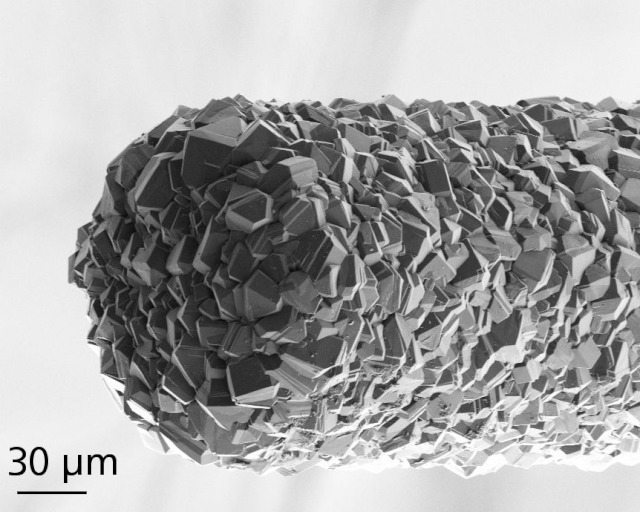

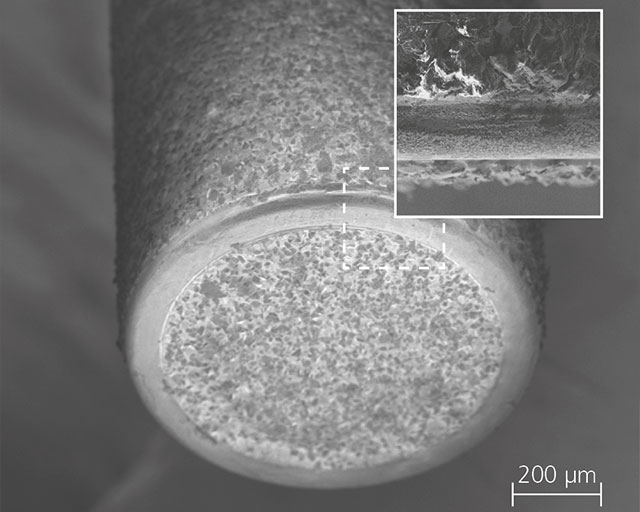

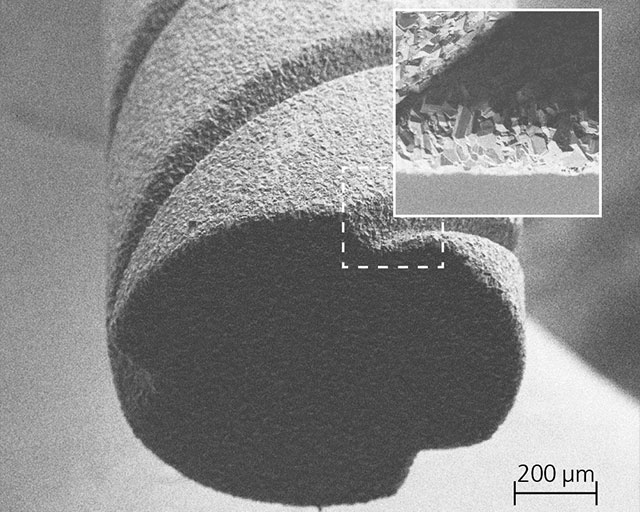

- Precise layer thickness determination in the nanometer to millimeter range by measurement of (cryo-)fractures or transverse sections

- Imaging optimized for elemental or topographic contrast, through the use of different detectors (Inlens, SE, BSE)

- Representation of the structure of materials through contrast optimization or etching of the surfaces

- Analysis of microdefects through fabrication of local precision sections using Focused Ion Beam (FIB)

- Production of lamellae for transmission imaging of the inner material structure