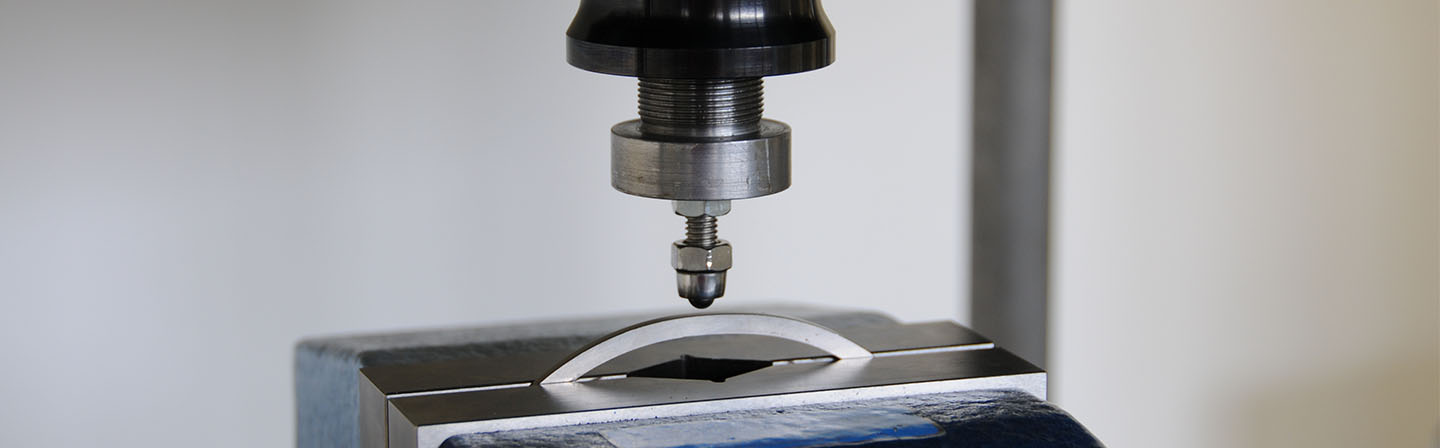

The impact test for testing the fatigue strength of coatings and materials under continuous load

Impact test of coatings

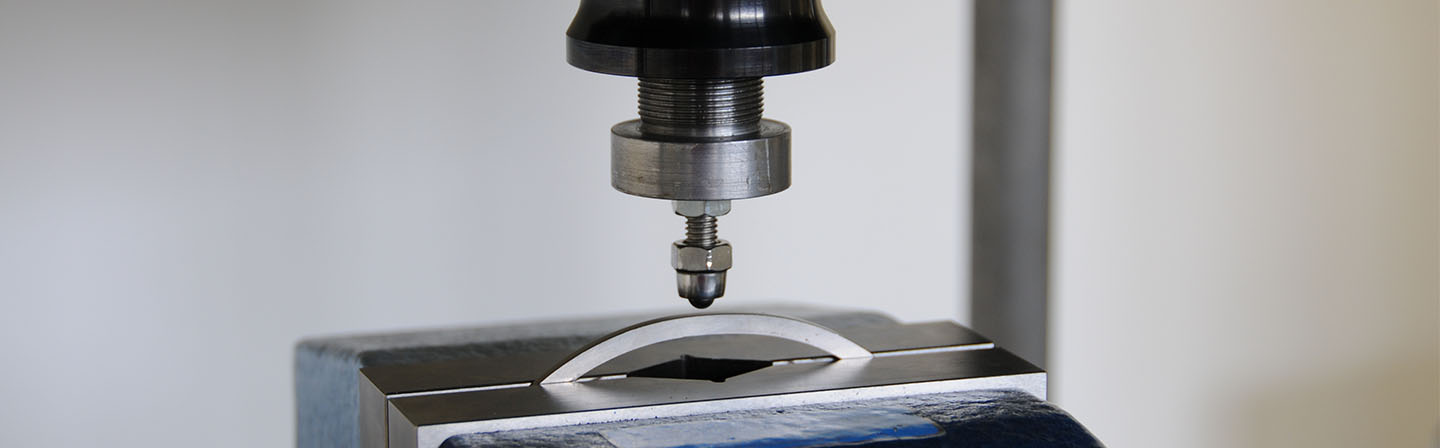

The impact test is a test method used to test the behavior of thick or thin layers, but also of solid materials with regard to permanent load. A fixed test ball exerts a long-term cyclic load (up to 1 million cycles) on the component to be tested. Depending on the area of application, the impact test can generate a fluctuating or repeated load (contact mode or lifting mode). The impact test provides a statement concerning the fatigue strength of the surface.

How the test is used

Die charakteristischen Prüfparameter beim Impact-Test sind:

- The characteristic test parameters in the impact test are:

- Load: 500 - 5000 N

- Duration: 100 - 1,000,000 cycles

- Frequency: 20 - 70 Hz

- Counterbody: carbide or ceramic balls

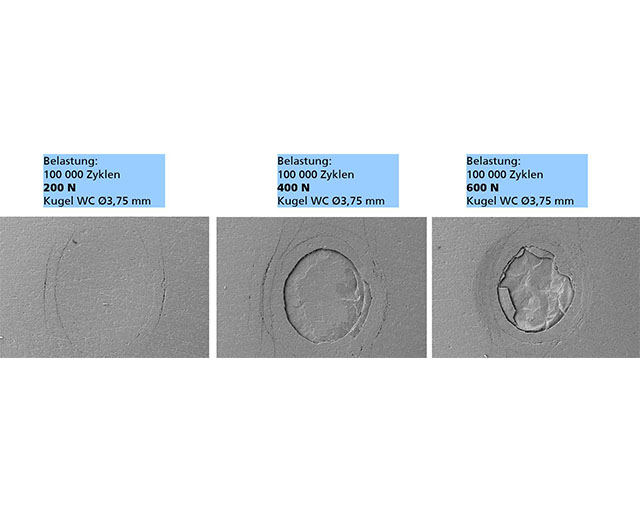

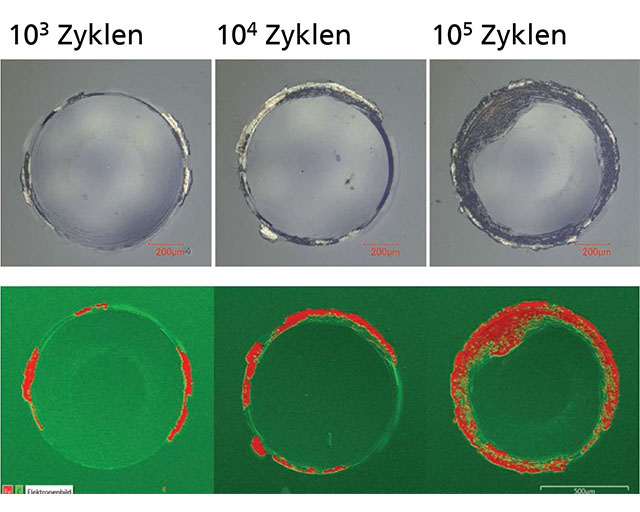

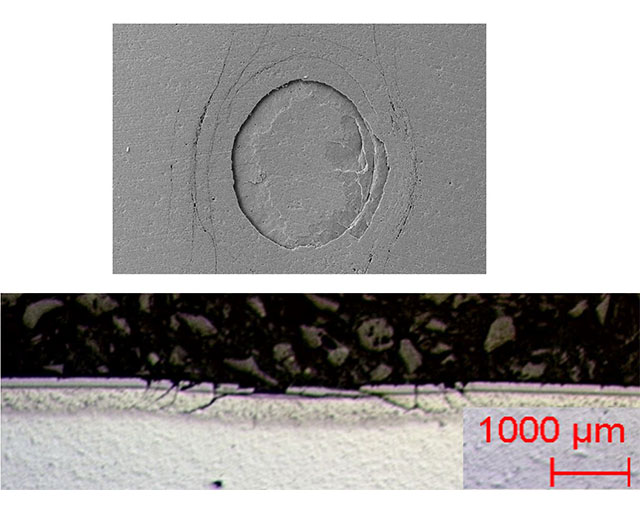

The evaluation is usually carried out under an optical microscope or a scanning electron microscope, whereby deformations, cracking or spalling can be documented and quantified, including in cross-section if necessary.

Load series (e.g. 1, 2, 3, 4, 5 kN) or cycle series (z.B. 102, 103, 104, 105, 106 Zyklen) are possible in order to determine the damage threshold or service life of the materials.