High-Power Impulse Magnetron Sputtering HIPIMS

The Fraunhofer IST has unique equipment at its disposal in the field of HIPIMS power supplies, plasma and layer characterization, and industrial plant technology

The Fraunhofer IST maintains an international network in the field of HIPIMS technology. Within this network, close contact exists with a large number of manufacturers of HIPIMS generators, suitable plasma diagnostics, and process monitoring and control. From the principal feasibility through to industrial pre-series or transfer to the customer, the Fraunhofer IST covers the entire range of development steps.

With the Fraunhofer IST, you have found the ideal development partner for the implementation of your ideas, from feasibility all the way to industrialization

The Fraunhofer IST has unique equipment at its disposal for the development of customer-specific HIPIMS processes. On industrial coating facilities with the latest pulse technology, individual projects can be realized - from feasibility through to scaling-up to production level. In addition to coating and process development, the Fraunhofer IST offers individual training and courses as well as consultation and support - from the initial idea all the way through to implementation with an international network.

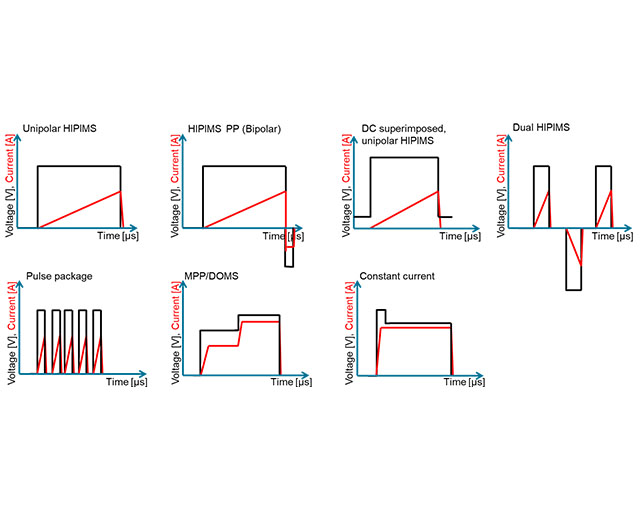

HIPIMS generators

The Fraunhofer IST has numerous commercially available HIPIMS generators at its disposal. Should the desired power supply not be included here, an individual solution can be found as a result of close contact with virtually all suppliers. Commercial HIPIMS generators are currently available at the Fraunhofer IST from the following manufacturers: hipV AB, Magpuls GmbH, Melec GmbH, nano4energy SL, Starfire Industries LLC, Trumpf Hüttinger, ZPulser LLC.

Specifications / Technical data:

- Unipolar mode

- Dual-magnetron mode

- Planar cathodes, tubular cathodes (single- and double-cathode arrangement)

- Constant-current pulse

- Positive reverse pulse

- Superimposed operation: HIPIMS+DC, HIPIMS+MF, HIPIMS+RF

- Deep oscillating magnetron sputtering (DOMS)

- Modulated pulse power (MPP)

Reactive HIPIMS process control

For the active control of reactive HIPIMS processes, the Fraunhofer IST uses systems from Gencoa (Speedflo) and PLASUS (EMICON). Furthermore, the Fraunhofer IST is developing solutions for active process control on the basis of lambda probes and, in cooperation with industrial partners, on the basis of optical emission spectroscopy.

Specifications / Technical data:

- Regulation by characteristic emission lines

- Regulation by ratios of different emission lines

- Regulation on multiple emission lines

- Regulation of electrical power supply parameters, e.g. fixed peak current

- Active power control by off-time modulation (WO07147582 A1)