Development of a sensory kingpin

Challenge

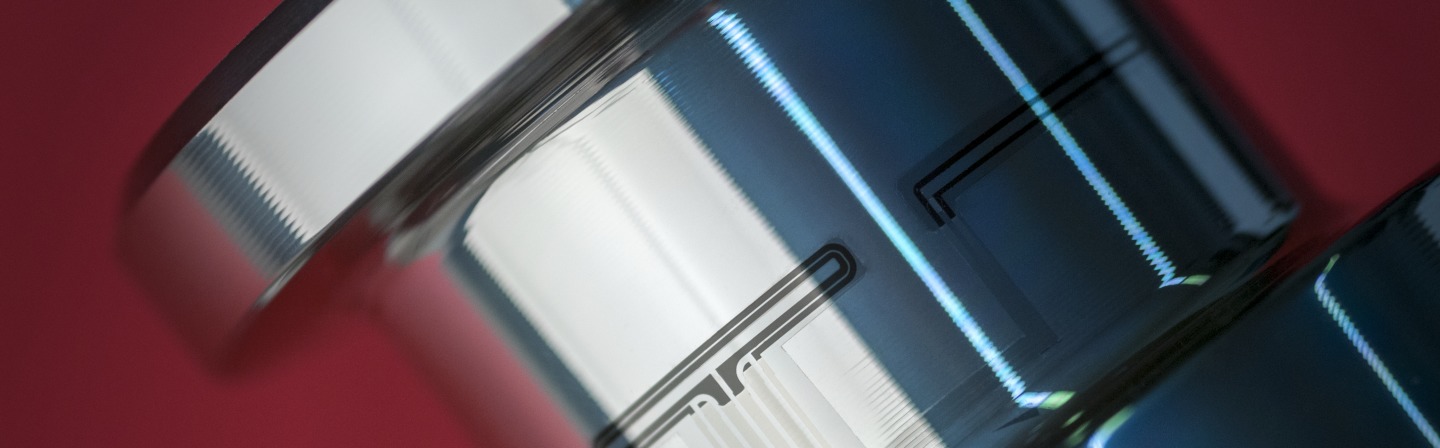

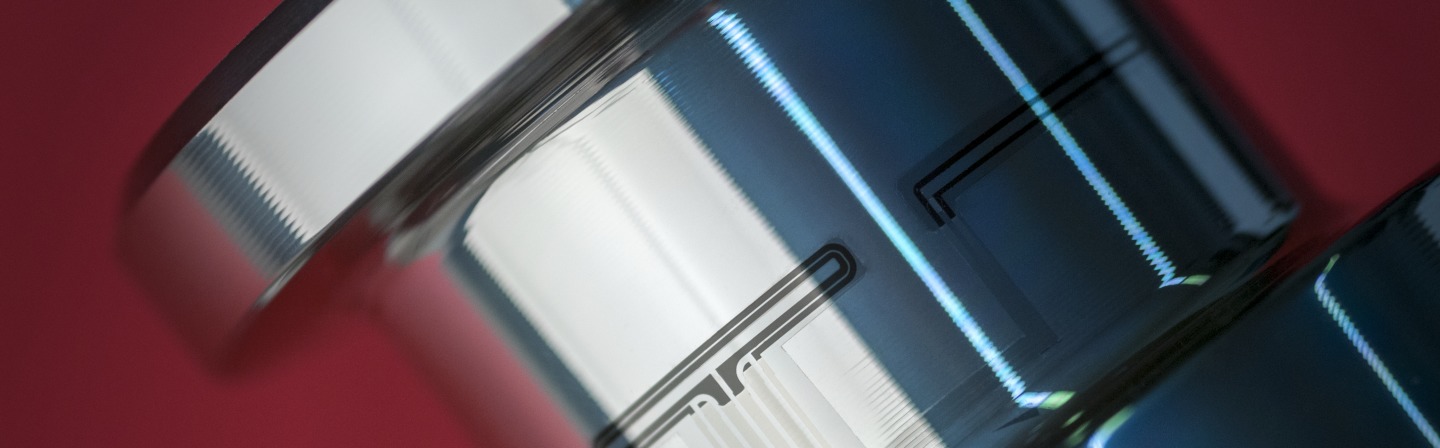

The task of the Fraunhofer IST within the project was the integration of thin-film sensor systems for measurement of force and temperature distribution in the main load zone of the complexly shaped kingpin, which is situated between tractor unit and trailer. The measurement of force by means of the sensory kingpin is important for the interplay of different components such as the electric drivetrain, traction battery and battery management system and is ensured by intelligent control algorithms.

Solution

At the Fraunhofer IST, a piezo-resistive thin-film system for force measurement was developed. For this, the film system presented in the adjacent lower figure is deposited and structured on the manually polished surface of the kingpin, which weighs 6 kg, in such a manner that the measurement areas are located in the upper part. The conductive paths to the contact areas must be routed over several edges, in order for them to be arranged in the lower screw-connection area.

Added value

The results of the local tensile force measurement of the sensory kingpin are used for control purposes in order to compensate for any tensile or shear force occurring in the trailer coupling. Energy from the braking power, which is recovered via the electric motors during downhill driving and then stored in batteries, can be made available to the vehicle again as drive power when required, i.e. during uphill driving or acceleration phases. The load on the towing vehicle is reduced, thereby minimizing energy consumption and CO2 emissions. As a result, the sensory kingpin developed by Fraunhofer IST contributes to the reduction of environmental damage caused by vehicles.