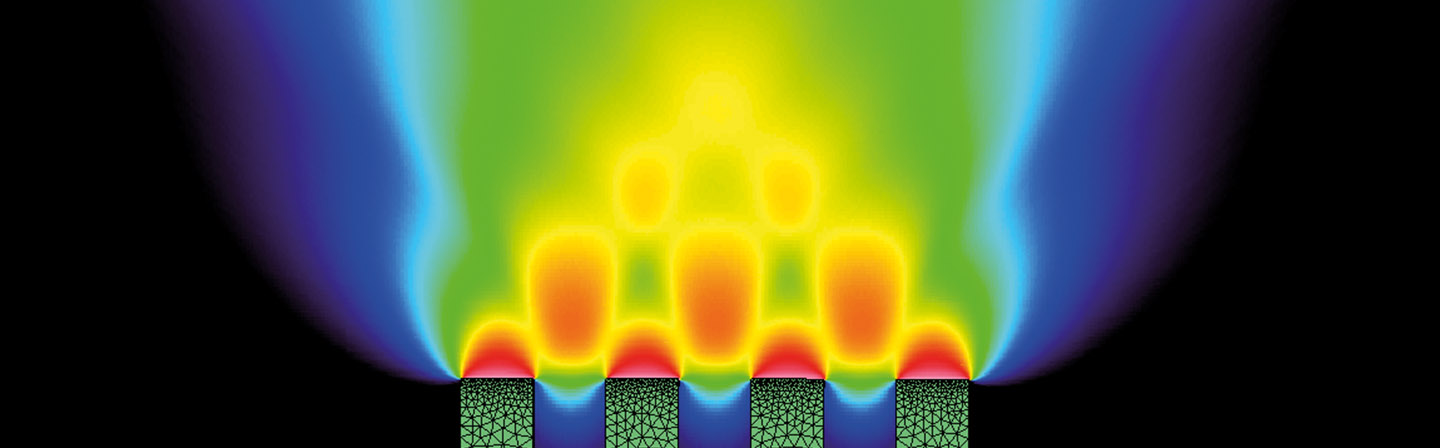

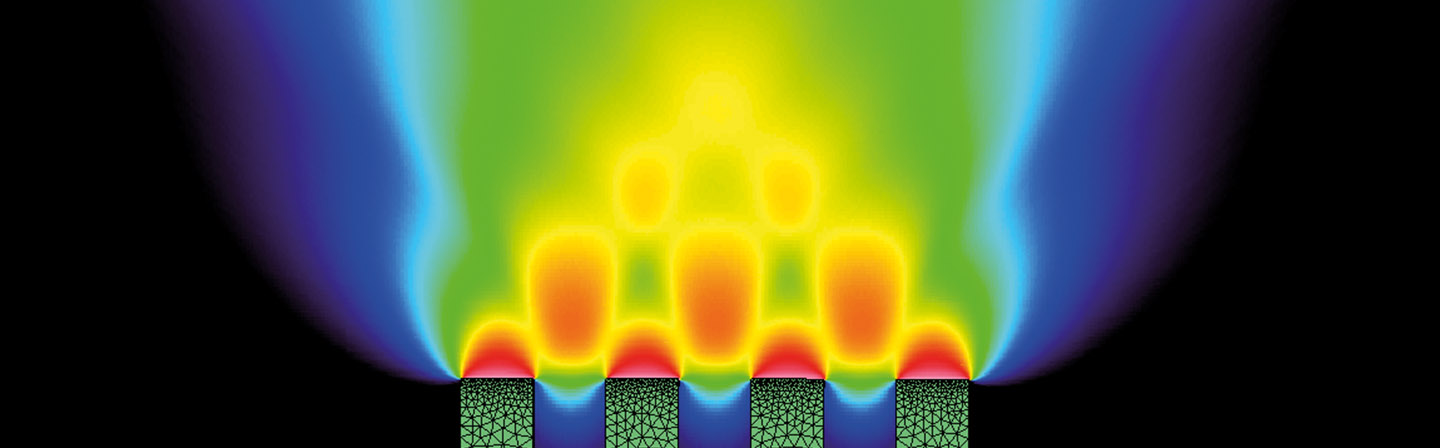

Direct Simulation Monte Carlo: Kinetic plasma simulation and transport simulation for coating processes with low pressure

Gas flow simulation for coating processes and transport simulation in combination with long-term process experience

Fraunhofer IST has long term experience in modelling of industrial deposition coaters and experimental validation. For this purpose, we use our own simulation software, which we have been developing for more than 20 years. The experience enables us to perform meaningful simulation case studies for novel coater concepts and judge the applicability of results. Besides of simulation studies we are also offering know-how transfer via courses, hands-on training workshops and licensing of our DSMC (Direct Simulation Monte Carlo) / PICMC (Particle-in-Cell-Monte Carlo) simulation software.

Model based product and process improvement, improved process knowledge

Product and process simulation enable to perform feasibility and optimization studies and require minimal experimental effort. DSMC and PIC-MC simulation allows to analyze the plasma dynamics, deposition rate uniformity and film stoichiometry also for 3D coater geometries and thus is a basis for decision making in the development of coater components and processes. Also, it often serves as a foundation for new directives, with which coating processes can be enhanced.