Although metallized plastics have been industrially produced and utilized for several decades now, the direct metallization of plastics still remains a highly topical issue. Due to the vast number of different plastics and the necessary individual development of intermediate layers and/or targeted pretreatment, there is a high demand for processes which enable a strongly adherent metallization of plastics. High power impulse magnetron sputtering (HIPIMS) is a process which offers considerable application potential in this respect. At the Fraunhofer IST, studies into direct metallization with aluminum and with chromium have been carried out; these studies have produced promising results with regard to the adhesive strength on plastics.

Direct metallization of plastics by means of HIPIMS

Direct metallization with aluminum

Within the framework of the investigation, various plastics were coated with aluminum. Thereby, no form of pretreatment outside the coating chamber was performed and no form of plasma pretreatment was used. After being enclosed, the plastics were coated directly with aluminum. Particularly for the polyamides PA6 and PA6.6 and for the polymethylmethacrylates (PMMA), an excellent adhesion (HK 0) could be achieved. As regards PMMA in particular, a direct plasma coating with reliable adhesion has not been known until now. Usually, a laquer is applied or an intermediate layer is vapor-deposited without plasma prior to the actual metallization. In the present case, it was determined that the fraction of ions plays a major role in the HIPIMS process.

The higher the ion fraction, the better the adhesion.In the case of plastics, differing behavior during the coating process can indeed occur if the substrates are obtained from different manufacturers. For PMMA, repeated tests have also shown that it is generally possible to achieve excellent adhesion.

Direct metallization with chromium

Particularly with regard to the EU REACH regulation and the prohibition of hexavalent chromium (Cr VI), both the widespread pretreatment with chromium pickling and the galvanic coating, if Cr VI is involved, must be replaced. Furthermore, the color impression of chromium layers which are produced using trivalent chromium differs from the familiar impression of Cr VI layers. Here, HIPIMS technology offers the option of overcoming both of these challenges.

Firstly, the HIPIMS coatings are characterized by very good adhesion to the substrates. It was even possible to produce an adhesive layer on polytetrafluorethylene (PTFE), whereby further development is required in order to achieve good to very good adhesion. Secondly, the HIPIMS chromium layers exhibit a bluish hue, as is familiar from many established coatings. In this case, very good adhesion values of HK 0-1 could again be realized for polycarbonate (PC) and polyamide (PA 6, PA 6.6).

Characterization of adhesion

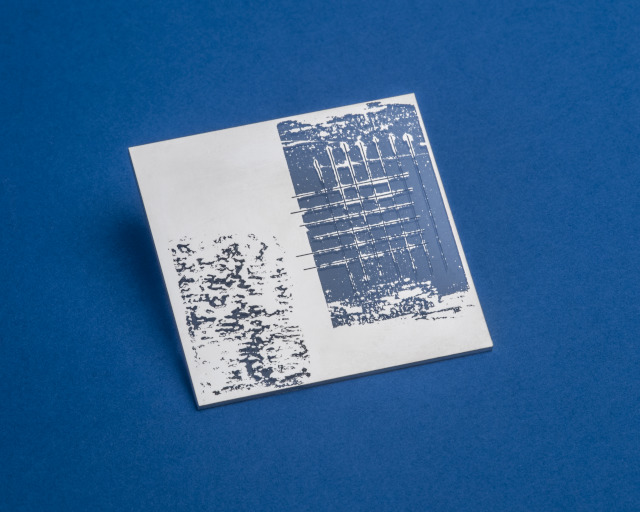

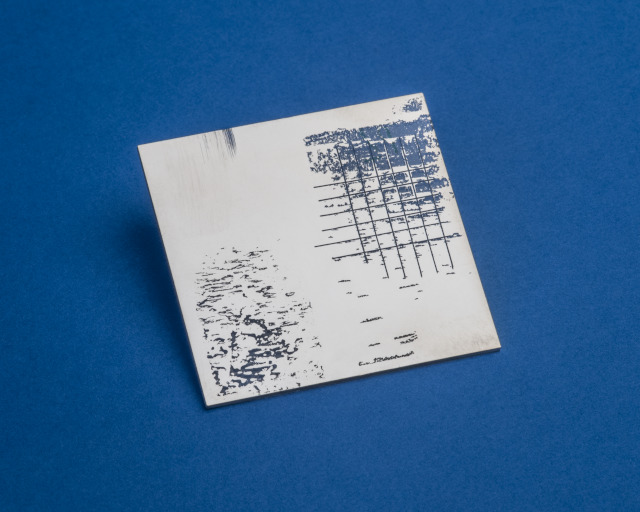

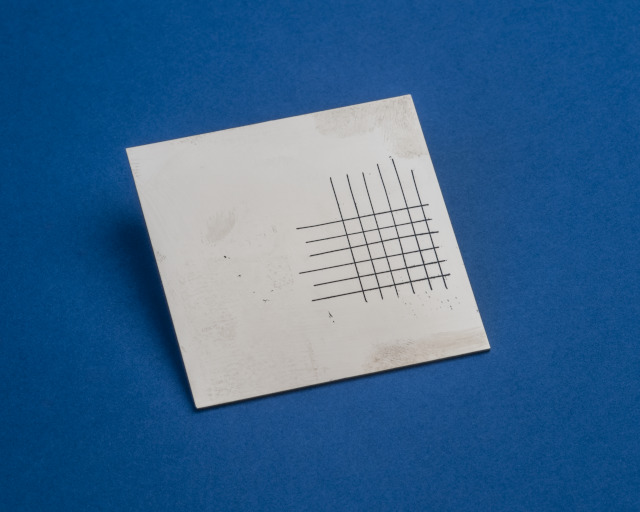

The characterization of the adhesion was performed by means of a combination of a cross-cut test in accordance with DIN EN ISO 2409 and a subsequent tape test. In the cross-cut test, a pattern is scored into the coated surface and the breakouts at the cut edges are evaluated. To exacerbate the situation, an adhesive tape with a defined adhesive force is applied to the scored surface and pulled off abruptly.

Outlook

The Fraunhofer IST has various vacuum systems (batch and in-line coaters) at its disposal with a variety of cathode sizes for the customer-specific development of HIPIMS processes. With its superb industrial equipment, the Fraunhofer IST is able to utilize HIPIMS in order to implement an adhesive metallization, either as a seed layser for further reinforcement or as a thin functional layer, without any additional processes, for various applications.

Please do not hesitate to contact us.